Healthcare

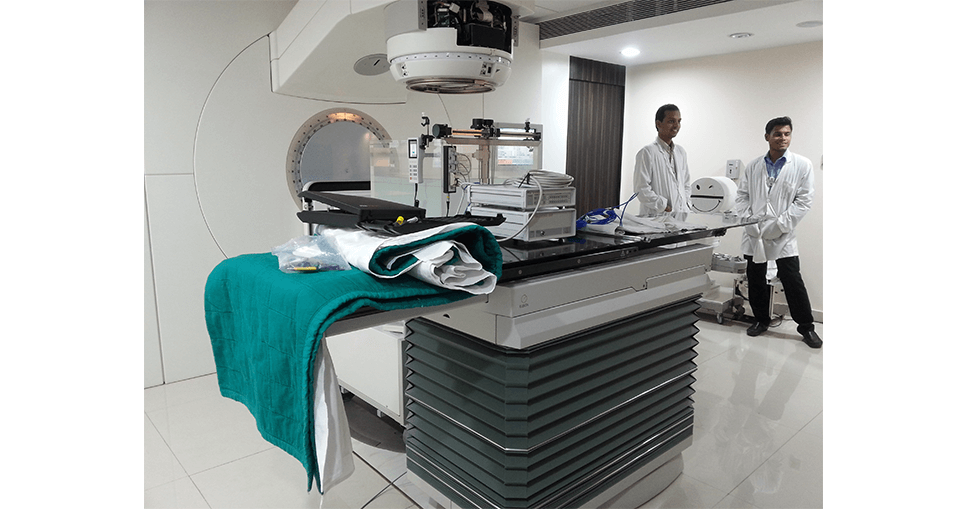

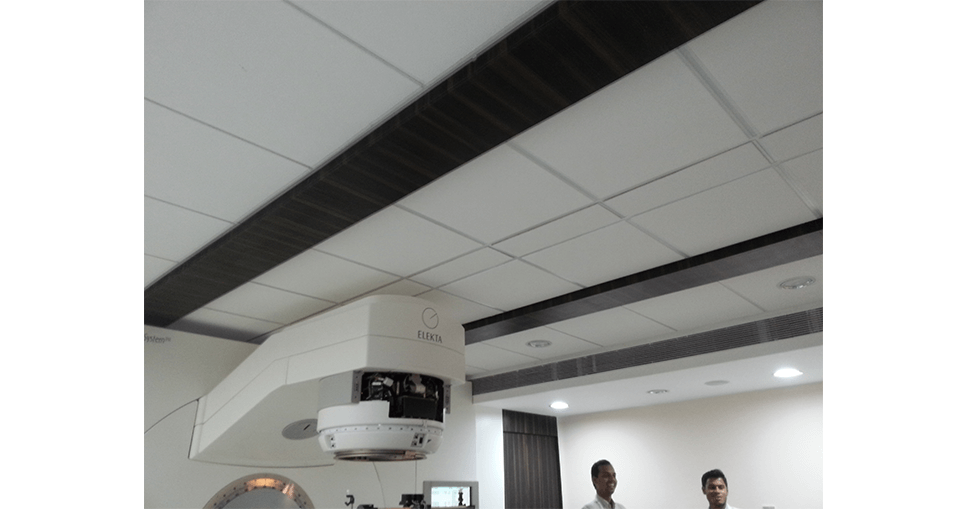

Radiation X-Ray Shielding

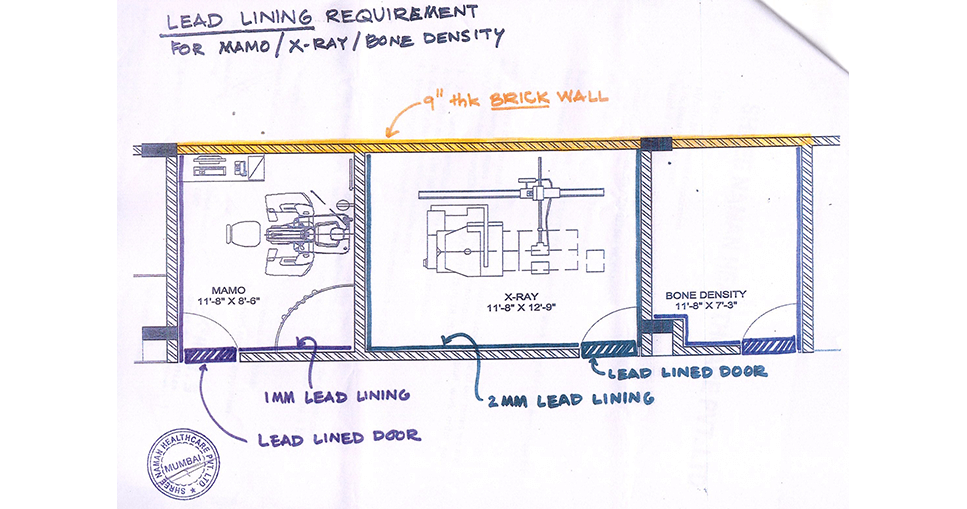

We offer complete Lead X-Ray Radiation Shielding Solutions for a variety of industries & facilities including hospitals, clinics, construction, industrial non-destructive testing, power generation, security & defence, aerospace, and nuclear.

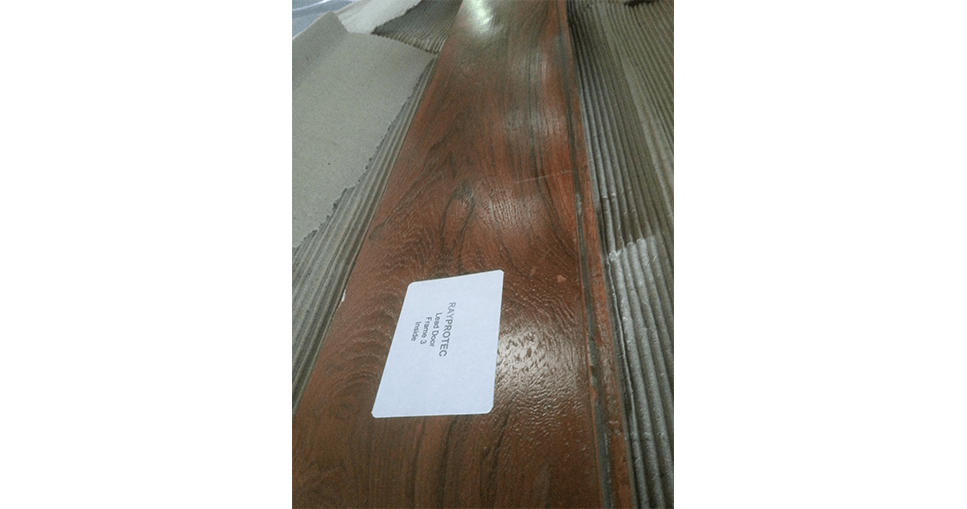

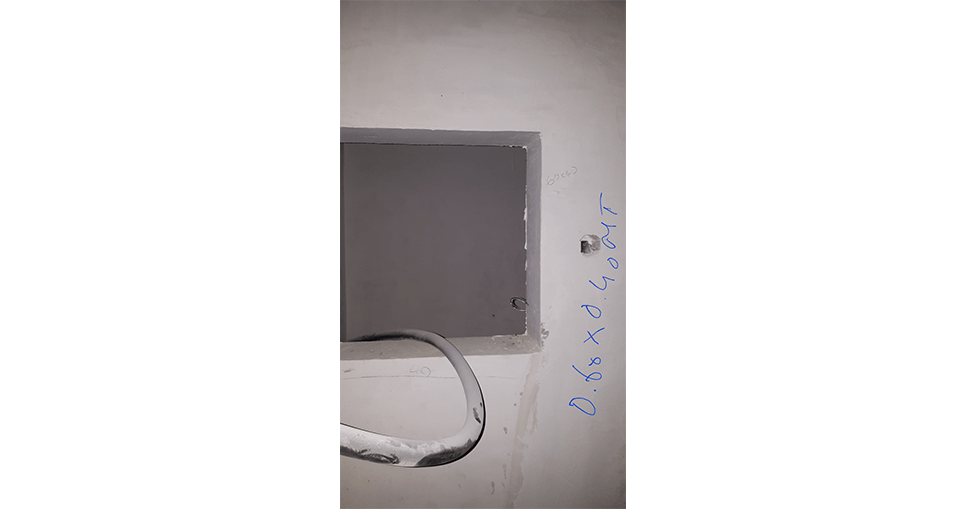

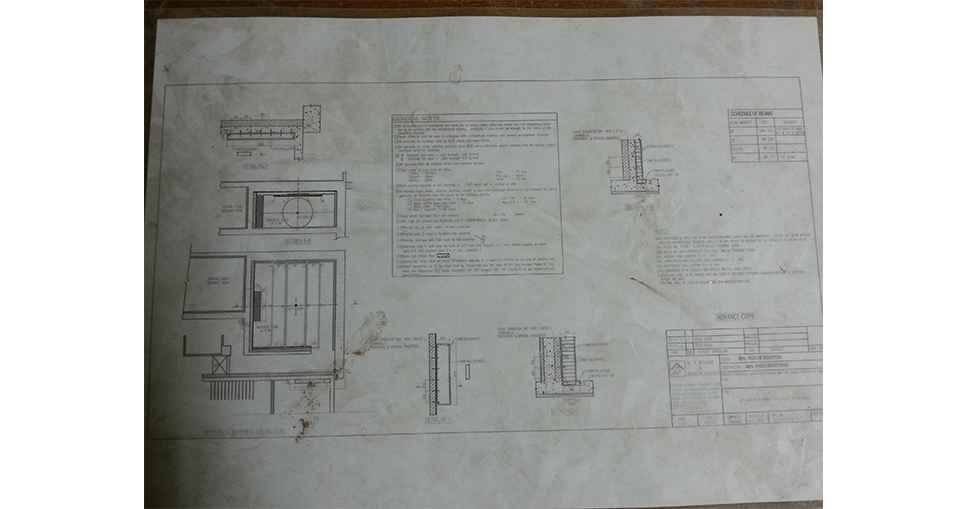

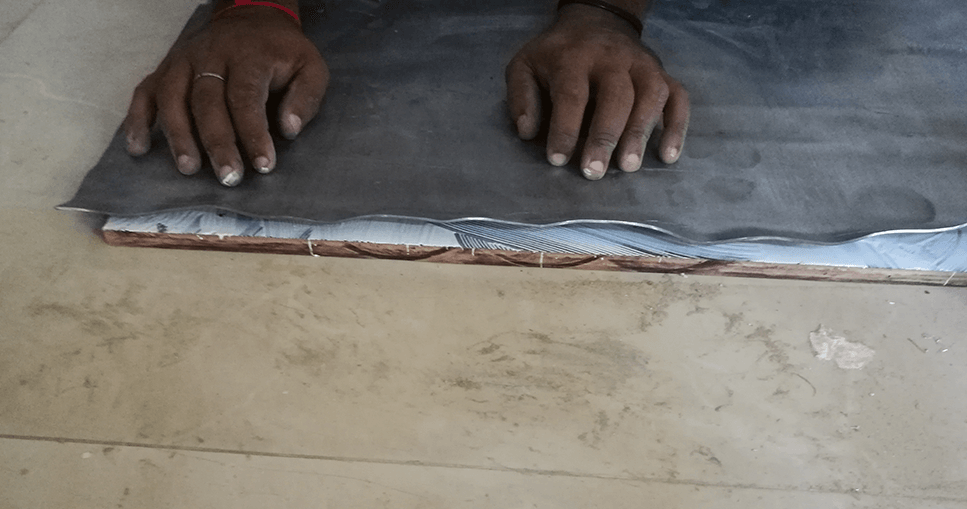

Lead Sheet is commonly used in medical radiation construction projects, lead sheet can be built into walls, doors and frames to protect medical personnel from gamma rays. It can also be used to stop radiation leakage from cut-outs and penetrations in lead-lined walls.

Lead Sheets & Lead Bricks are an ideal solution for your radiation shielding needs. Our lead sheet meets and exceeds Federal QQL-201 and ASTM B749 standard specifications.

Our high quality lead sheet can be adhered to drywall, plywood sheathing or other substrates. Lead Sheet is a very effective to protect medical personnel as well as the general public and the environment from potentially dangerous levels of radiation from x-rays and gamma rays and electron beams.

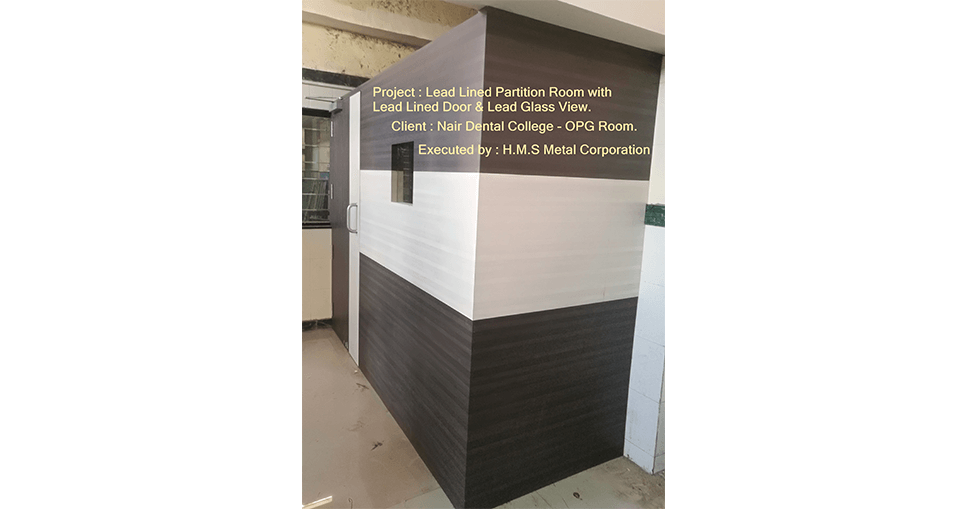

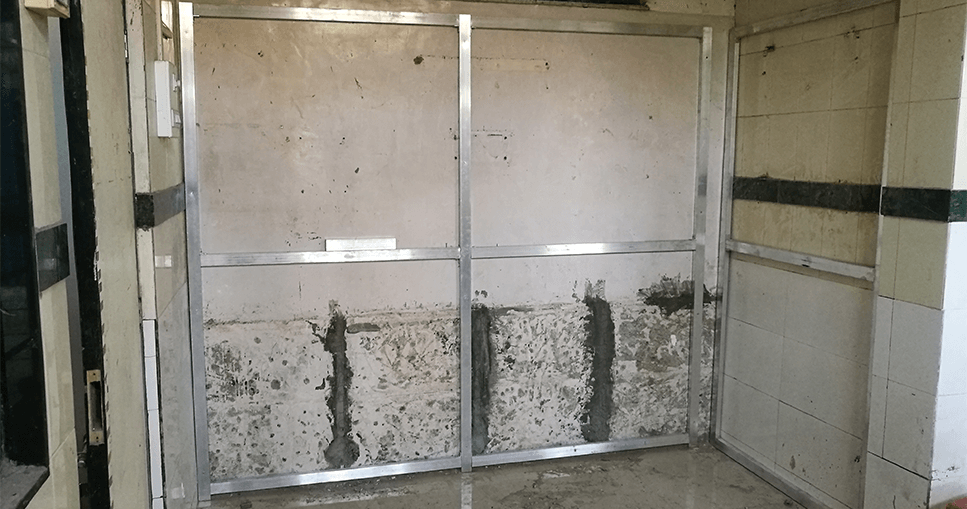

HMS Metal manufactures and customizes all lead and lead-based products used in diagnostic shielding applications. We have supplied the construction and medical industries with innovative products matched to only the best in service. Our wide variety of customized lead radiation shielding products includes such as

- Manufacturing Lead Sheet/Plate/Bricks for Radiation Shielding.

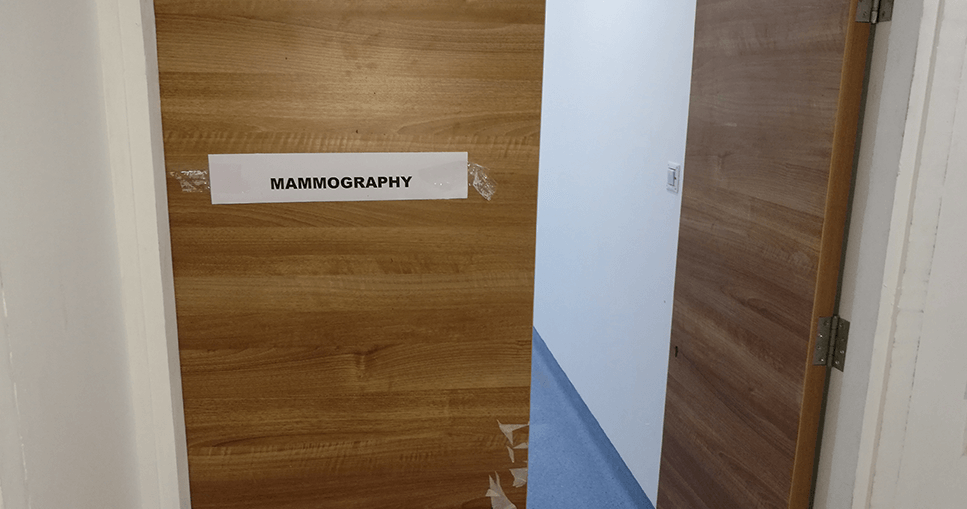

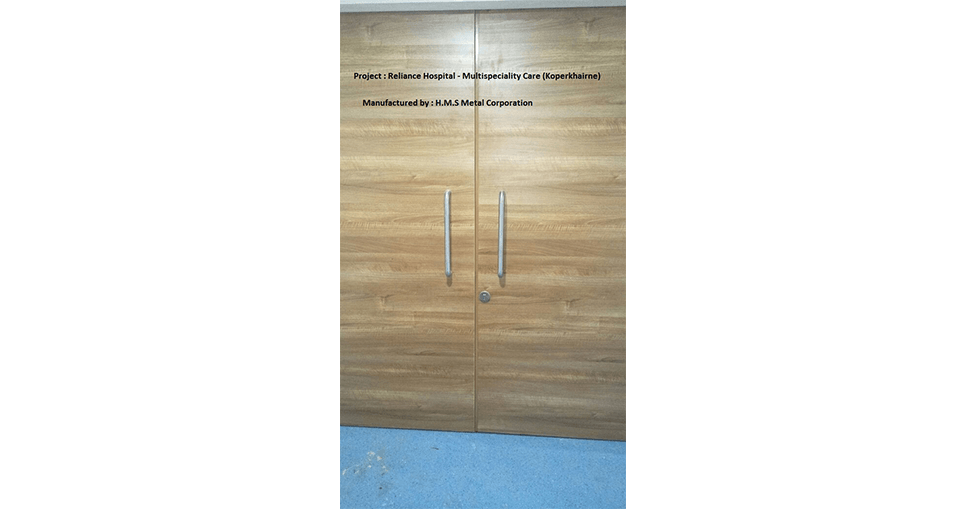

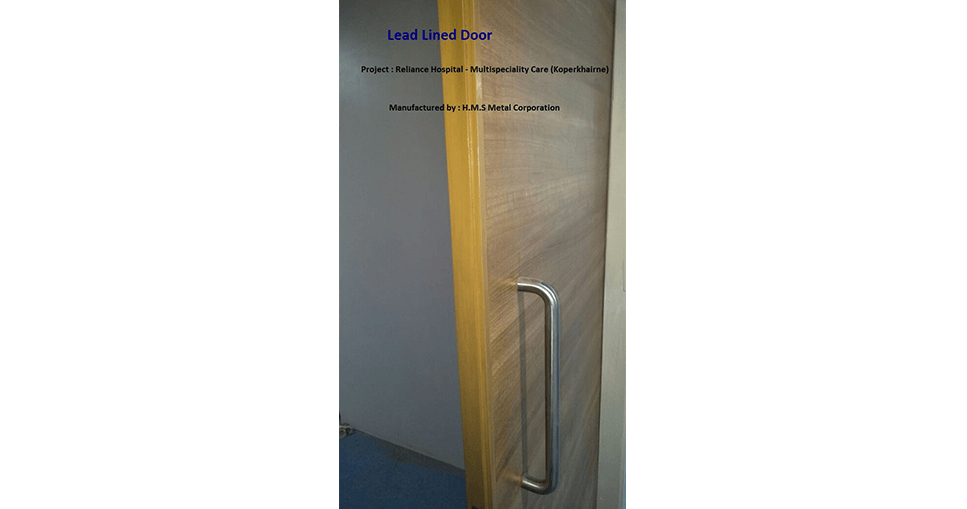

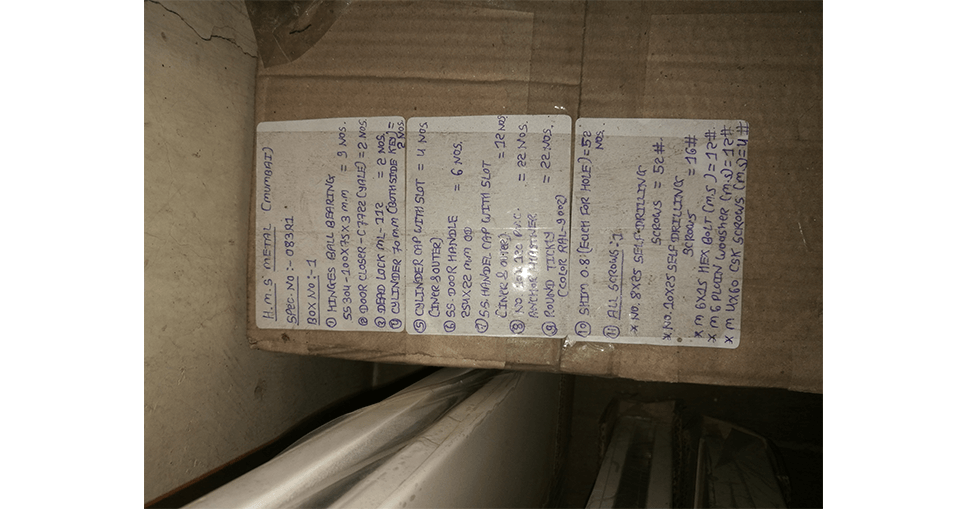

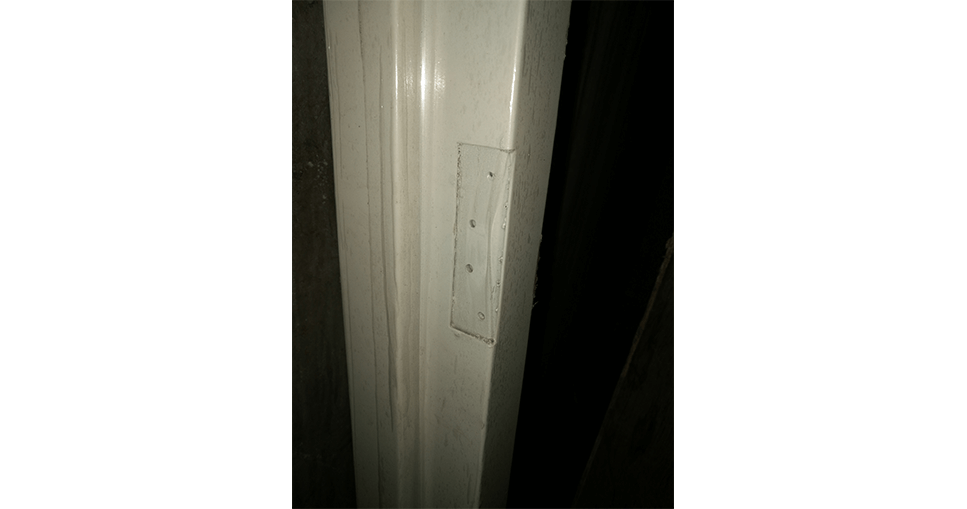

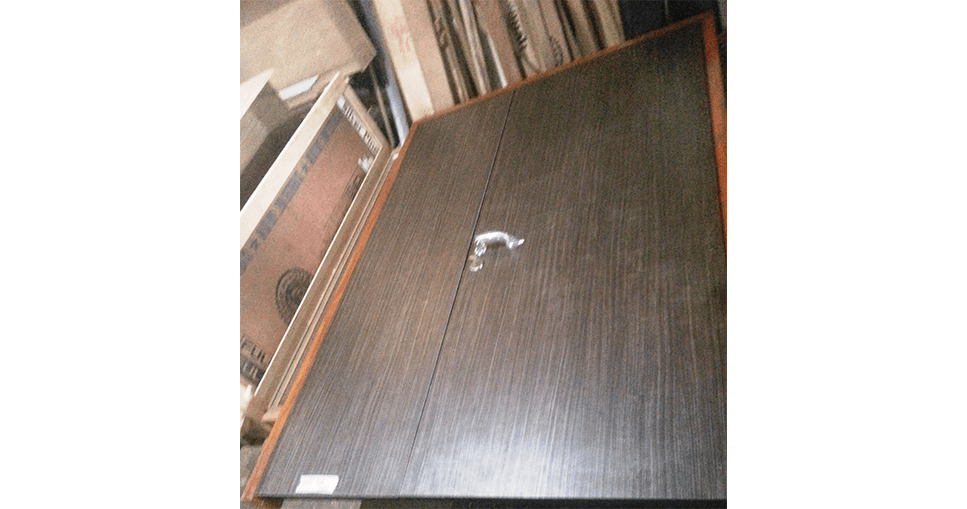

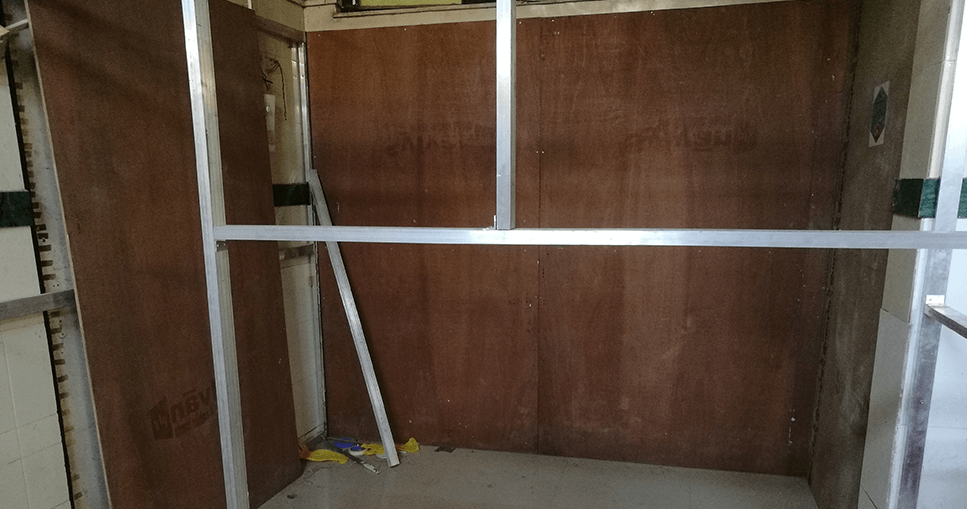

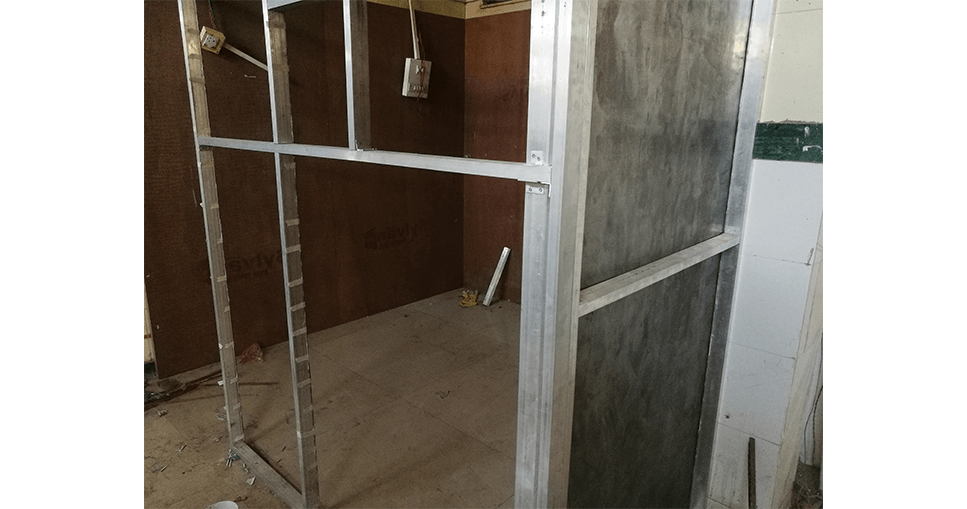

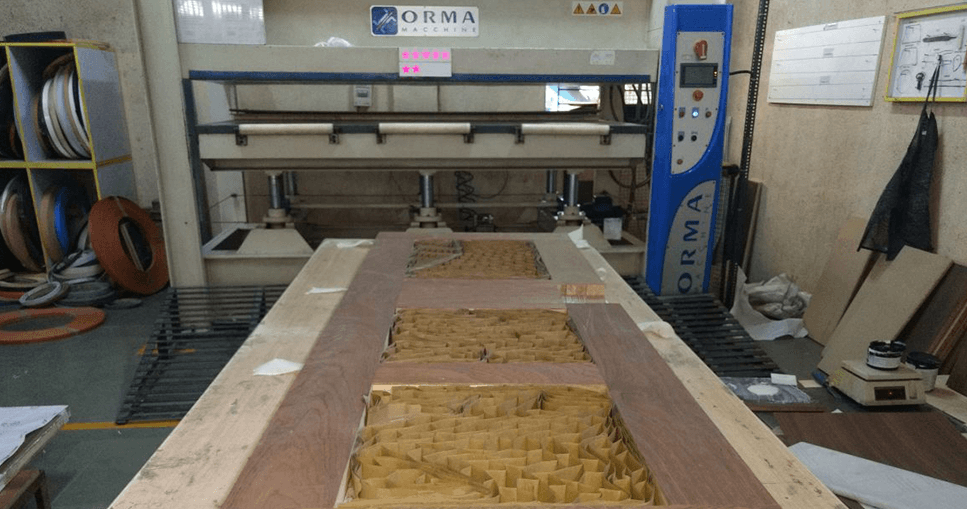

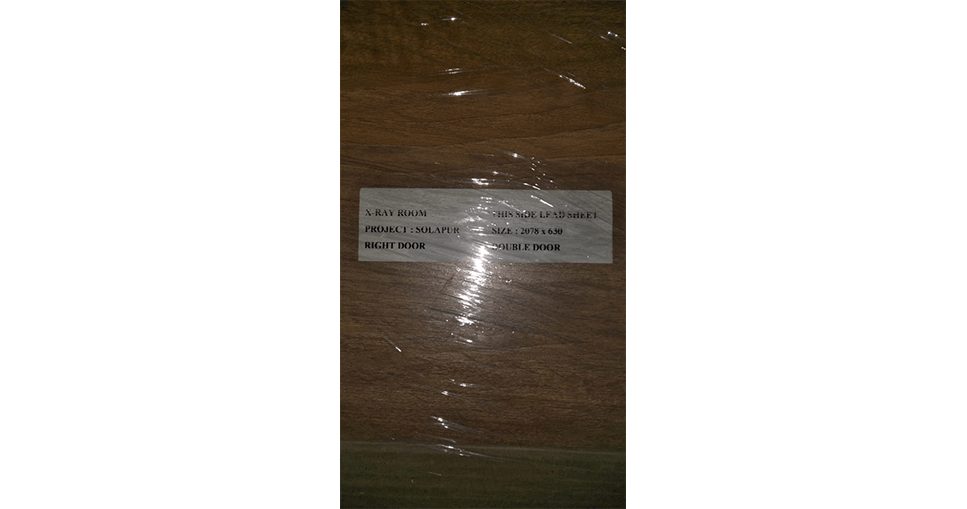

- Modular Factory Press Lead Lined Wood Doors of your Size up to width 1200mm with Door Frame & with complete required Hardware accessories.

- Powder Coated GI Lead Doors & SS Lead Doors

- X-ray Mobile Shield of GI & Wood with Lead Glass & Castor Wheels.

- Lead Lined Partition & Rooms for Dental X-Ray & Imaging Rooms.

- Lead Lined Plywood / Drywall of Gypsum/Fiber Cement Board.

- Lead Glass.

- Lead Apron.

- Lead Goggles.

Lead and some of its alloys are generally the most cost effective radiation shielding materials to protect against the effects of alpha rays, gamma rays and x-rays. The properties of lead shielding which make it an excellent shielding material are its uniform density, high atomic number (82), high level of stability, ease of fabrication, high degree of flexibility in application and its availability at reasonable cost.

Chemical

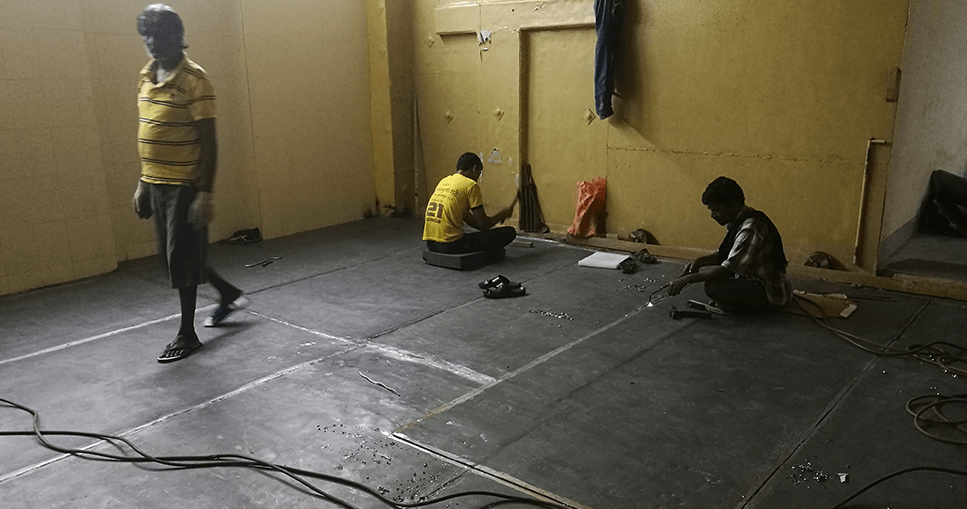

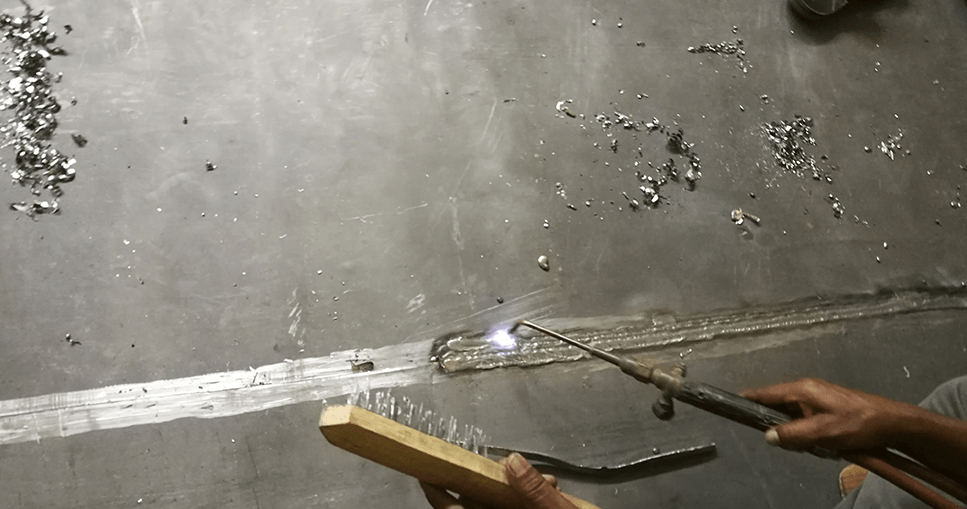

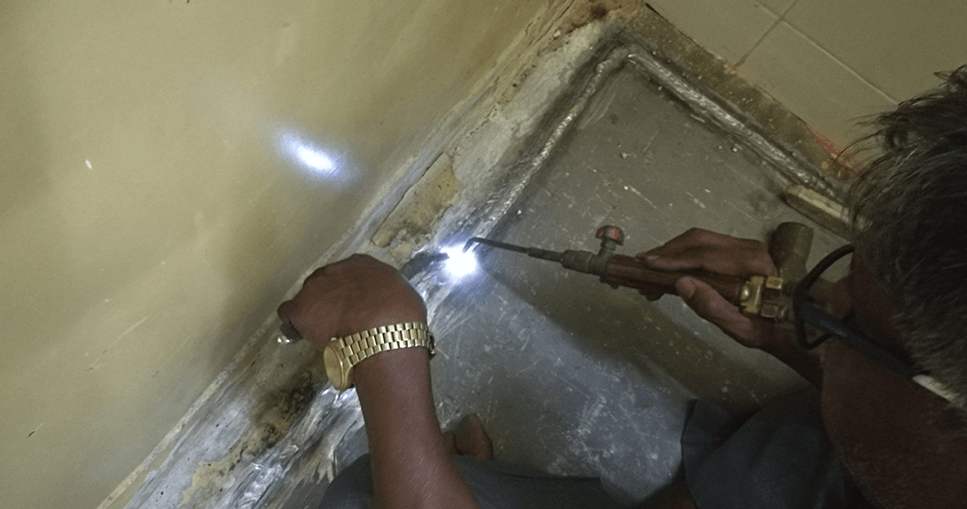

CHEMICAL – TANK / VESSEL LEAD LINING

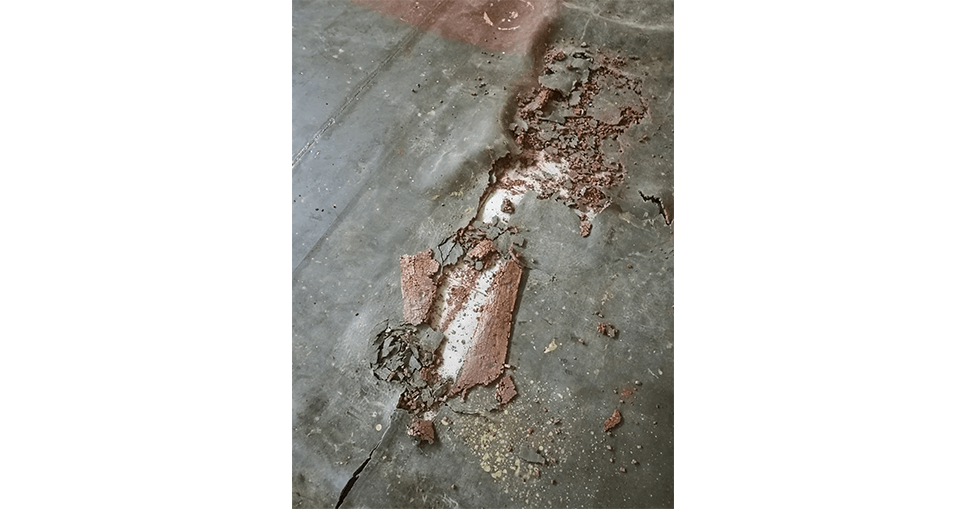

By virtue of its resistance to chemical corrosion, Lead Sheets finds use for the lining & bonding of chemical treatment baths, acid plants and storage vessels/tanks.

Lead is highly appreciated in apparatus construction for the chemical industry and primarily for nonferrous metallurgy, thanks to its special properties such as corrosion resistance to highly aggressive media, high electrical conductivity, great density, good malleability and low melting point, as well as the fact that it is particularly easy to repair. In most cases, lead needs a base or structural material because of its relatively low strength.

HMS Metal produce varying grades and alloys of lead to provide precise degrees of corrosive resistance demanded by the most stringent design requirements and can be bonded to most products, using either a loose or homogeneous lining method.

The inert nature of lead makes it ideal for lining of chemical tanks and components used in chemical processes particularly where acid exposure is involved.

Lead is used in a variety of applications across the Chemical and Refining industries.

These include:

- Lead lined tanks for chrome plating, anodising or pickling

- Anodes for copper electro winning, copper foil production, chrome plating and anodising

- Lead lining for transport vessels for hazardous chemicals, such as phosphoric acids and bromides, to provide a long lasting chemical resistant coating

- Repair and maintenance on existing equipment, such as wet electrostatic precipitators, cooling or heating coils etc.

We can supply certified lead in any alloy such as ASTMB29.

Refining

Lead Anodes for Electrowinning & Electrolytic Refining

We produce world class, high conductivity, low corrosion Lead Anodes for metal refining purposes across the globe.

Lead Anodes are widely used in mining, electrowinning & electrolytic refining of metals such as copper, nickel and zinc.

Electrolytic refining is a process of refining bmetal (mainly copper) by the process electrolysis. As far as the mechanism of the process is concerned, duringelectrolysis, a large chunk or slab of impure b bmetal is used as the anode with a thin strip of pure metal at the cathode.

Today, practically all of the world’s copper production is electrorefined, constituting by far the largest electrolytic refining industry. The process closely related to electrorefining is electrowinninng with insoluble anodes. In this process, the metal is dissolved chemically. The pure metal is then “electrowon” using insoluble anodes, like Lead Anodes.

Accosutics

Lead Soundproofing for Noise Reduction

Lead has a high surface density and is correspondingly heavy. It can provide a very effective sound barrier compared to plaster, glass, concrete or many other materials. Also many other materials tend to become more rigid as they become thicker, rigid materials do not make good sound insulators since they can retransmit sound though vibration and resonances.

Lead, on the other hand, is soft and malleable. This makes it impossible to radiate sound and very difficult to be set into vibration, and has the flexibility needed to make a good sound barrier. Since lead is a metal it has a uniform density compared with wood and other materials and finally it is easy to attach with adhesive bond to gypsum board or plywood to produce structurally sound walls.

Acoustical Lead Sheet has been developed to help control noise in various interior environments: hospitals, schools, office buildings, industrial plants, apartment buildings and other multifamily buildings.

Lead is commonly used as a barrier that absorbs, sound, vibration, and radiation, as a result, lead sheet is commonly used as a sound deadening layer in the walls, floors and ceilings of sound studios. Noise is a challenge for many industries, including the music industry and in many factories with loud machinery. Lead sheet is 10 times more absorbent than glass or concrete and up to 100 times more absorbent than wood.

Marine

Lead Ballast for counterweights

Due to the many practical and protective properties of lead, it is widely used for Marine applications.

The high density of lead makes it an excellent material to use as ballast for vessels and counterweights.

We produce ballast and counterweights for vessels in any size, shape or form you need. From shot and molten lead filling our Standard lead ingots start at 25kgs, but we can supply ballast weighing many tonnes.

A wide range of sizes and lead alloys are available using zinc, copper, tin, antimony, calcium, silver and bismuth.