57+ Years Of Experience

HMS Metal Corporation HAVE BEEN in Business of LEAD SINCE 1964. We are global specialists in this field. We innovate and define the industry standard. Our mission is to build long-term customer relationships, and to exceed their expectations in quality, delivery and cost.

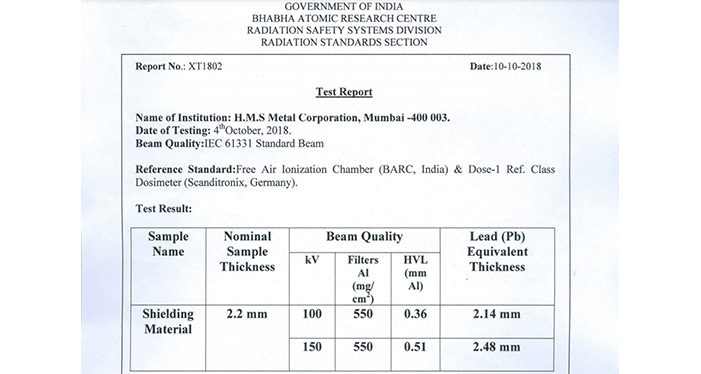

Meeting the highest quality standards of lead manufacture from our ISO, CE & AREB Certification to our internal quality control measures.

DOWNLOAD BROCHUREOur QMS

With Quality Management System (QMS) in a company. QMS impacts a company at every level, from daily administrative operations, to product development, marketing and sales, and through post-market customer service.

DOWNLOAD BROCHUREOur Excellence

- Best business management practices

- Business ethics and good governance

- Quality focus and Innovations

- Advanced marketing and branding strategies

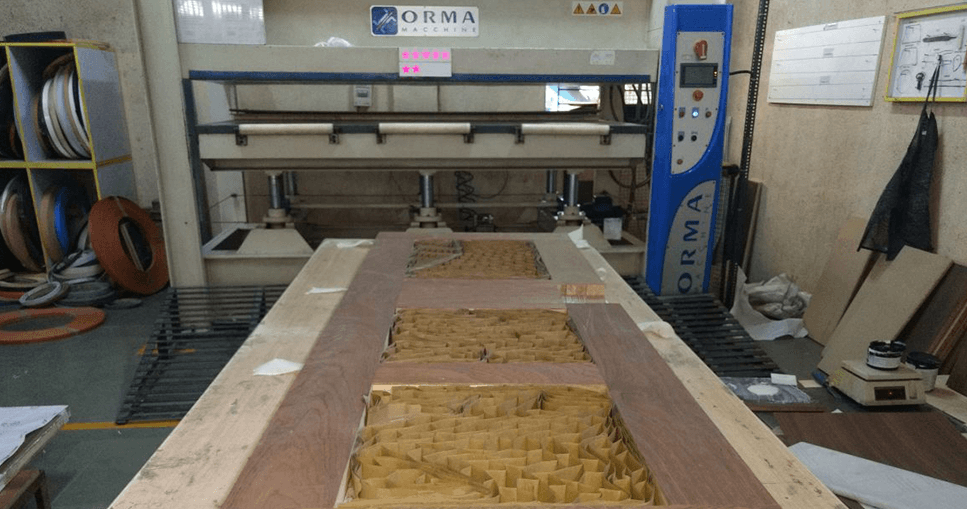

Our Innovation

For decades, the company has been a name that resonates trust, quality and innovation for LEAD Industry. Our Quality standards have gone international & Innovation is well innovation. It changes, it evolves and for us, it has bought in an advantage. A distinct advantage, evident in every inch we expand.

DOWNLOAD PDFOur Values

Our core value is “Business Ethics” which leads us to competitive edge in our Business. We understand present Business Challenges & we constantly invest in Business continuity planning & convert Adversity into Prosperity through Transformation.

DOWNLOAD BROCHUREHMS Metal gives you those assurances.

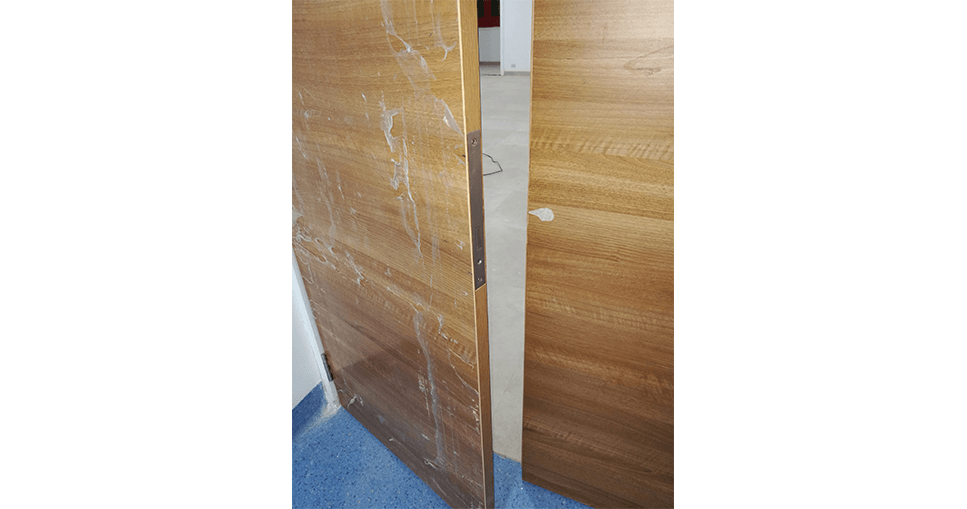

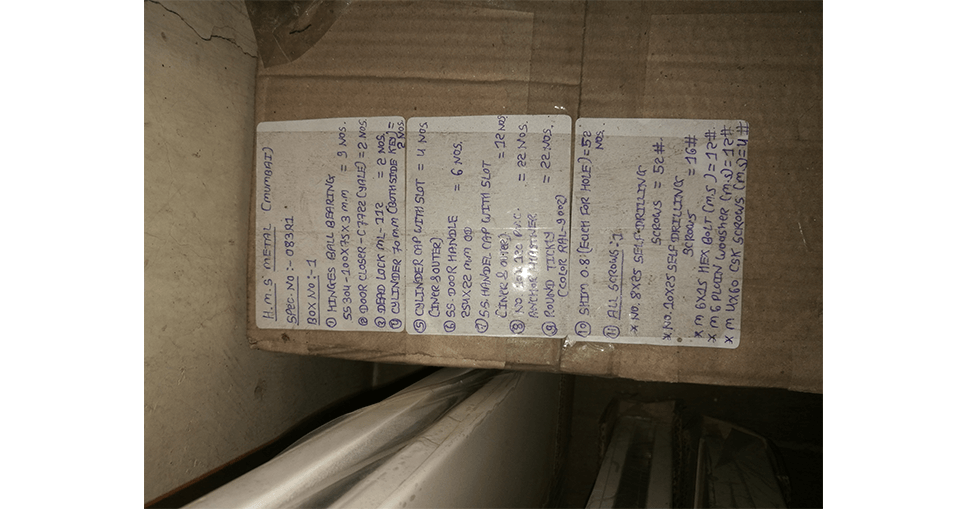

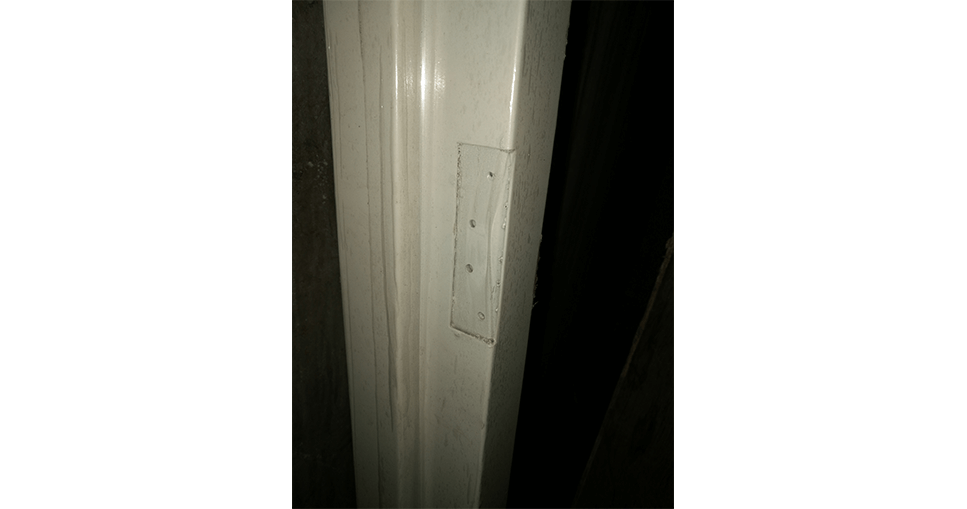

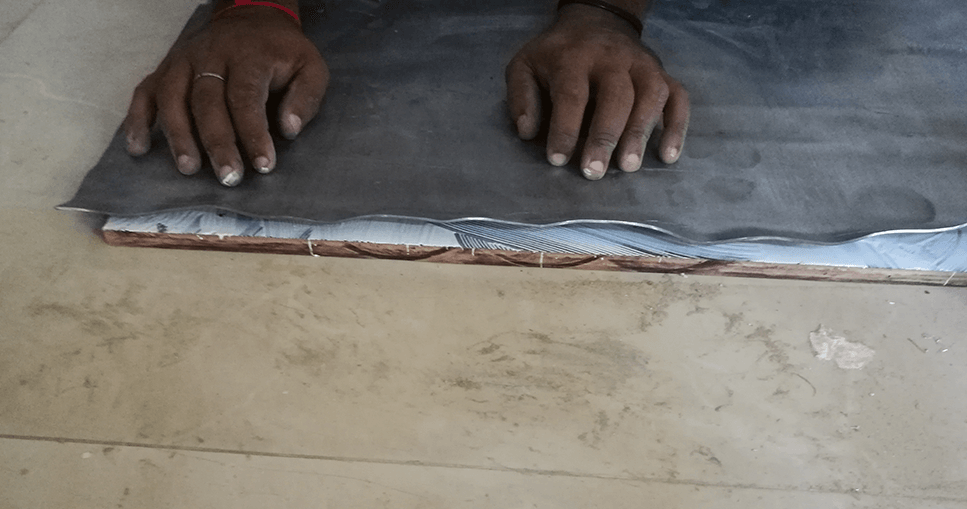

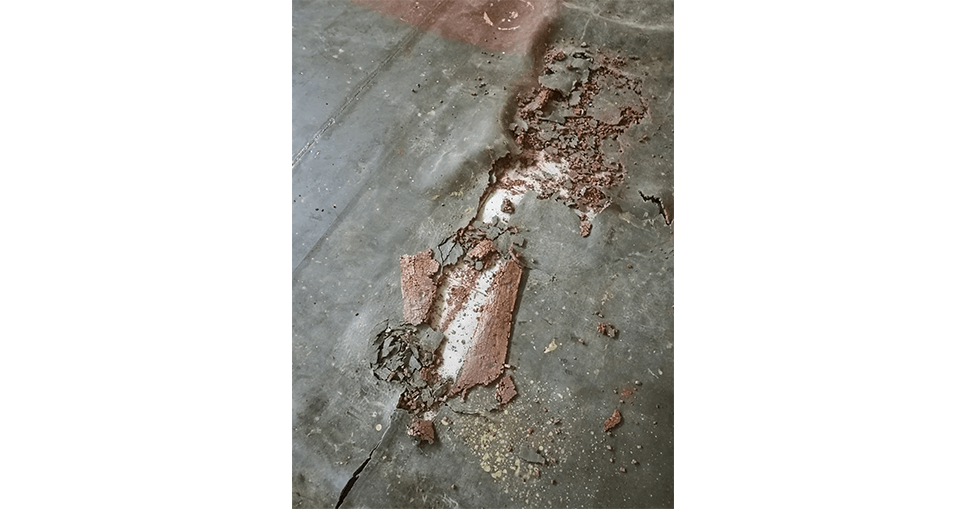

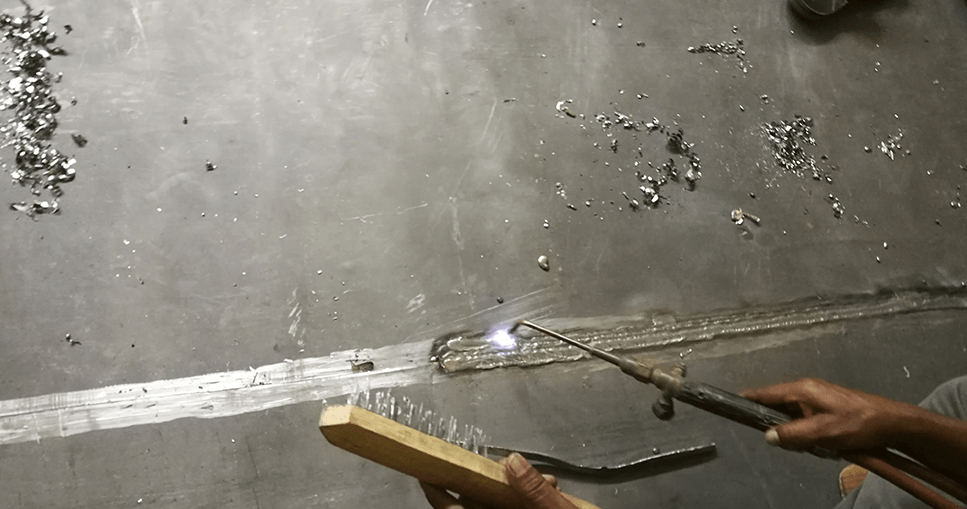

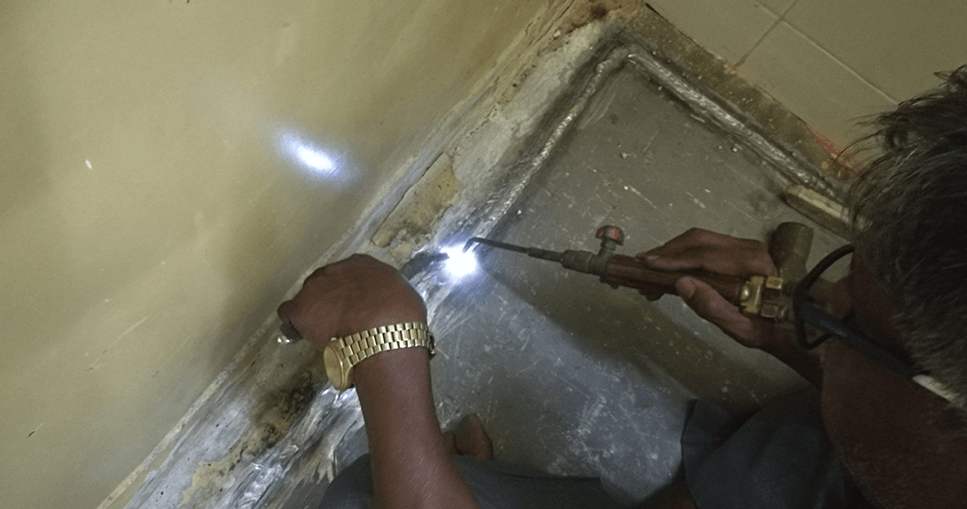

Every single lead product is subjected to rigorous quality checks throughout the entire process from manufacture to despatch. During production constant in process inspection is carried out to check for any pinholes or cracks cause during production. Upon material ready, inspection for proper size & thickness is done for any possible quality issues.

STANDARDS

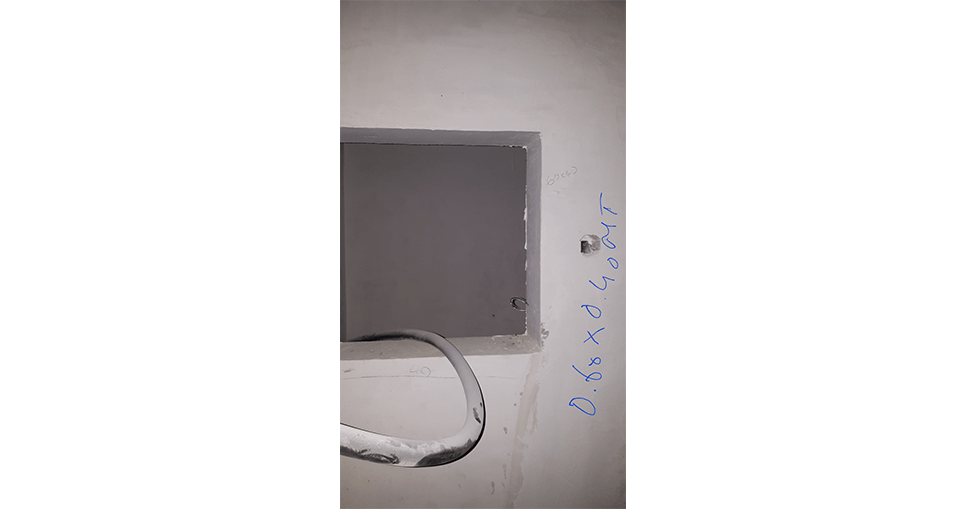

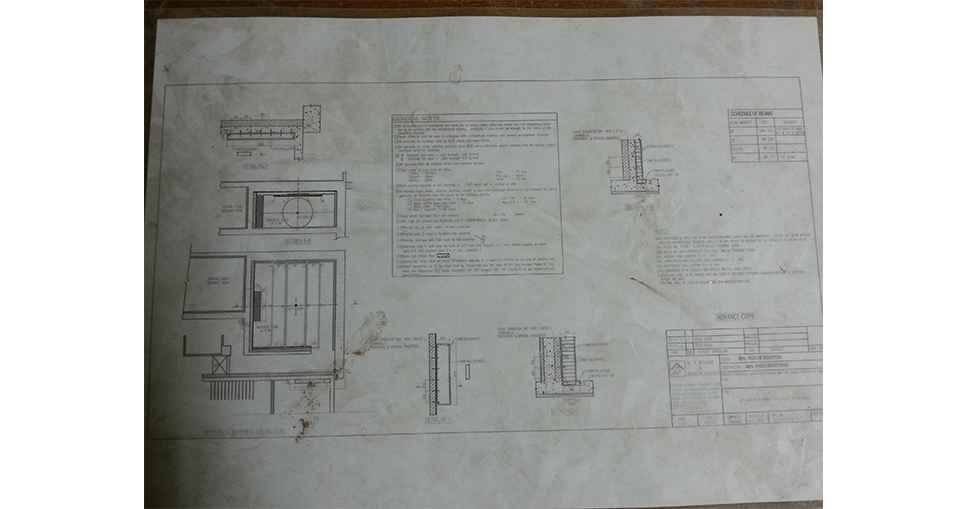

We produced Lead sheet to BS EN 12588. Under this standard, the thickness consistency of the sheet must not exceed a tolerance of +/– 5% at any one point and the alloy used must conform to quality of not less than 99.774% lead. Such is the consistency of the process that lead sheet will not vary in

thickness by more than +/- 5% at any given point.

It is this consistency, which means the performance of rolled lead sheet can be predicted with confidence to ensure optimum performance when specified and fitted correctly in any given application.

Thickness consistency is one of the key attributes that sets Rolled Lead Sheet apart from all other methods of manufacture. Lead can expand and contract considerably due to temperature variations.

Lead Sheet with a consistent thickness will expand and contract at an even rate.

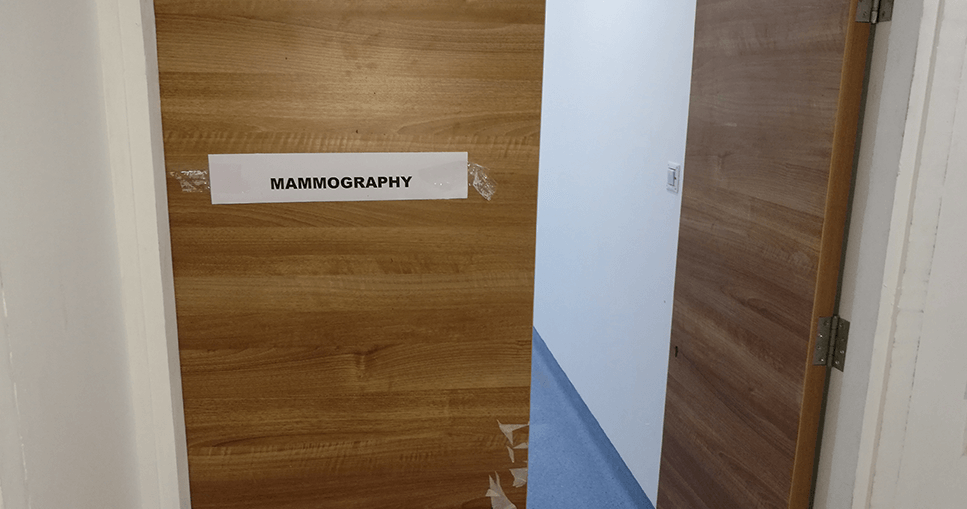

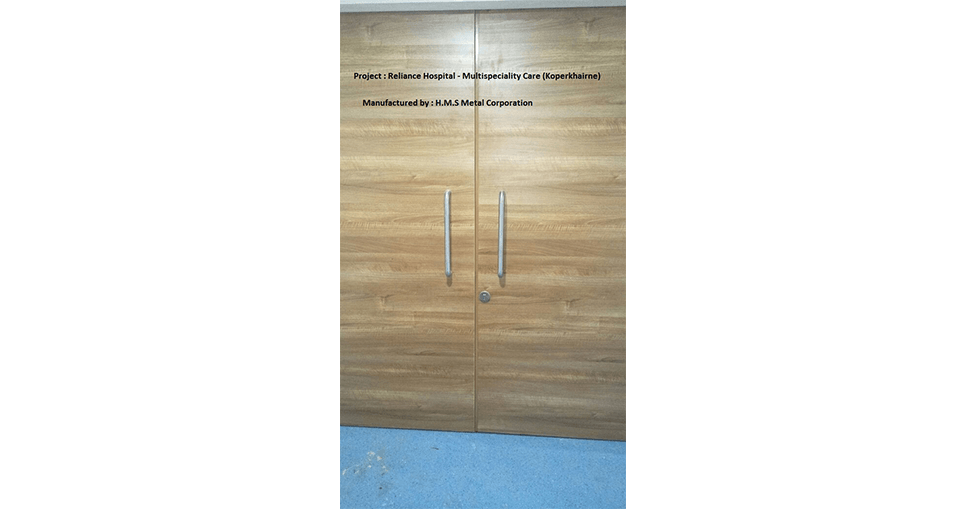

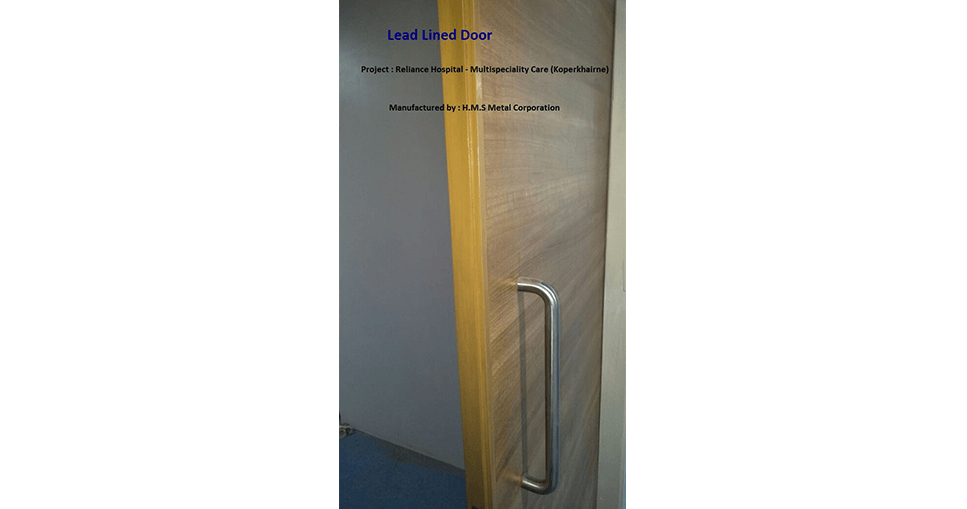

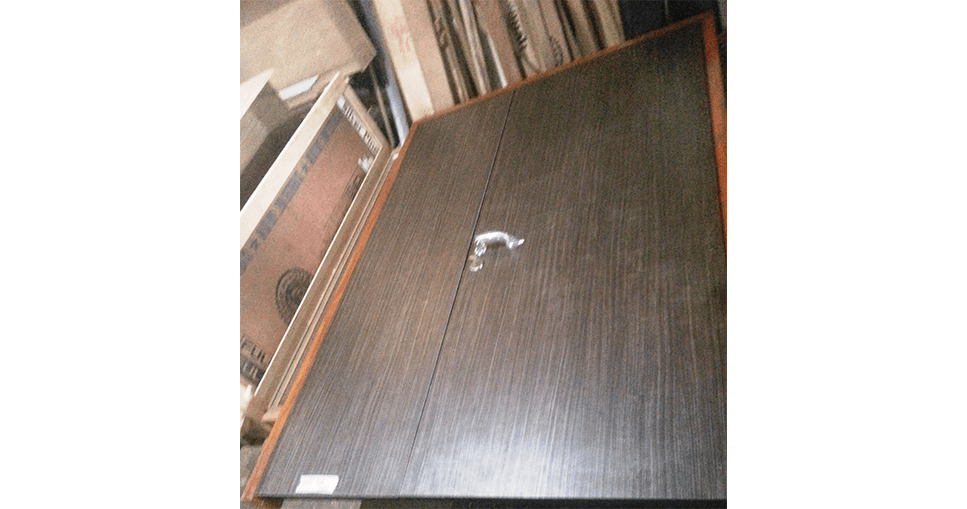

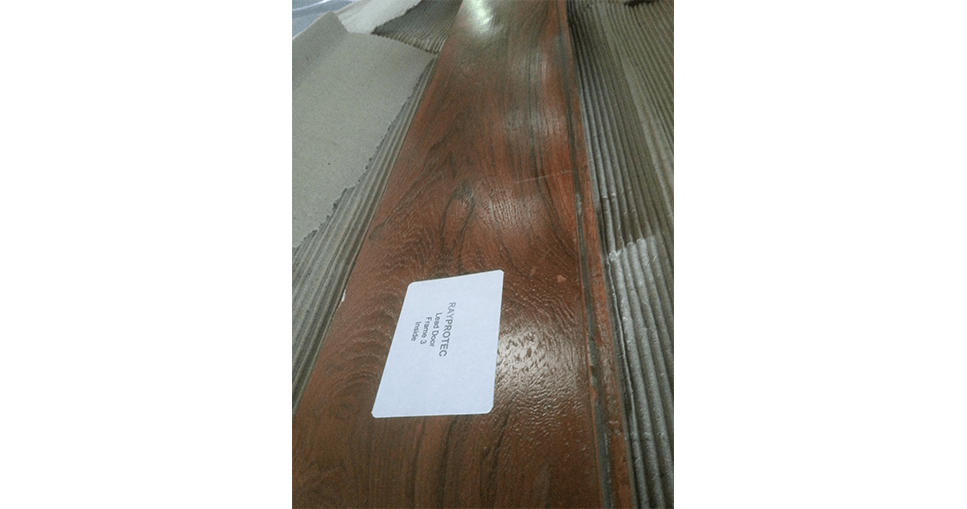

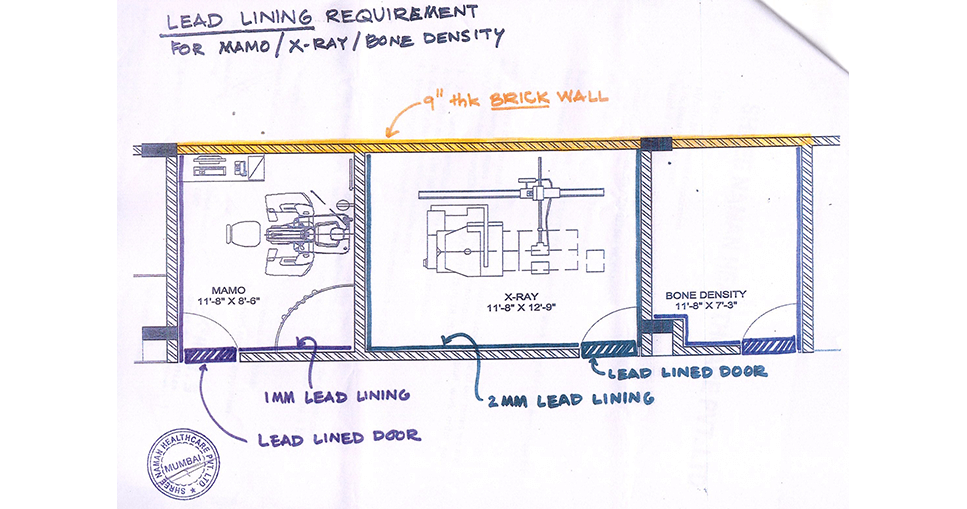

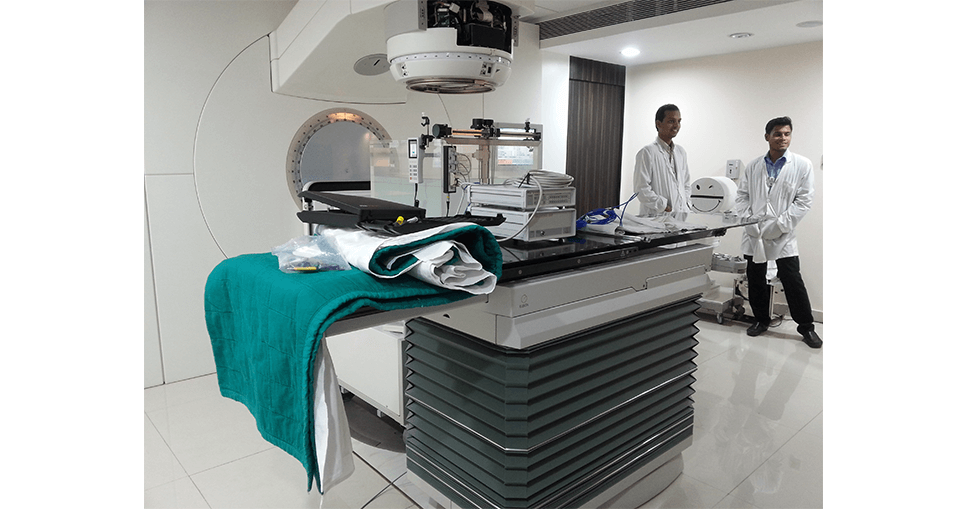

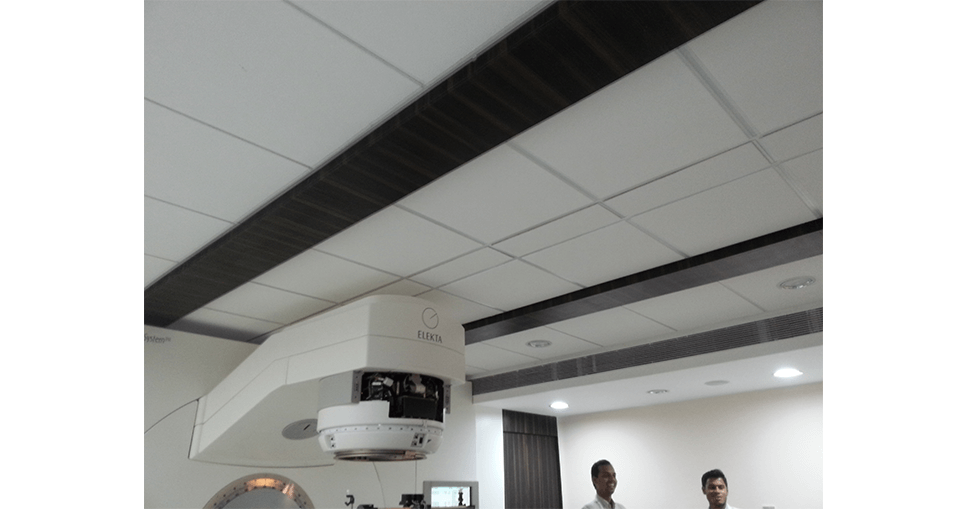

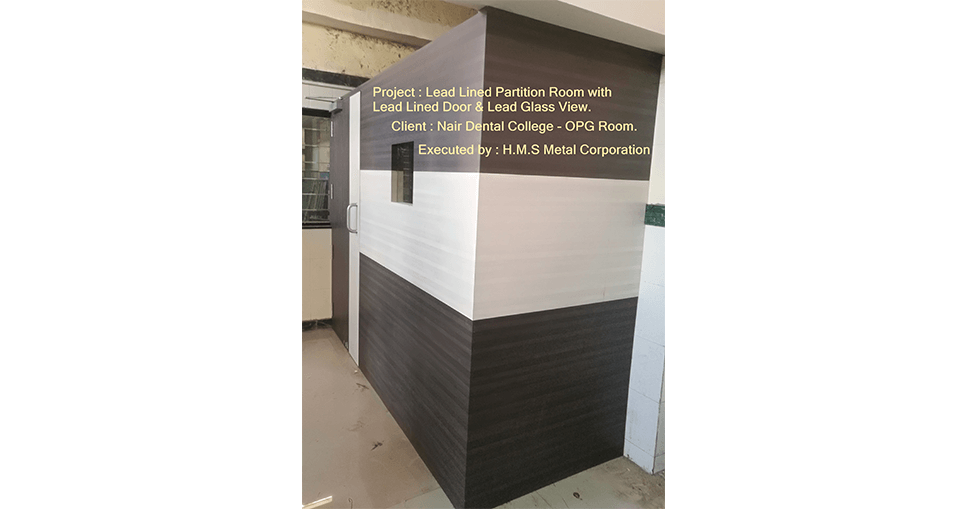

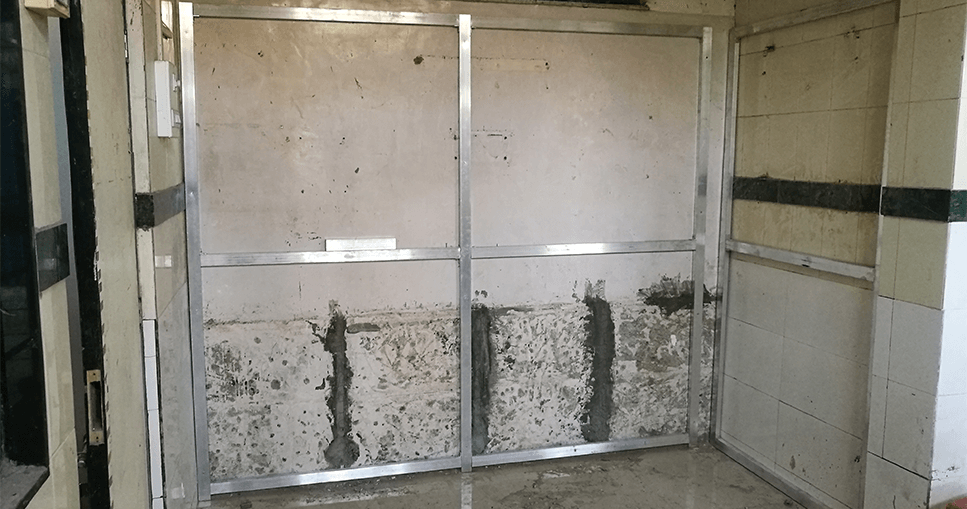

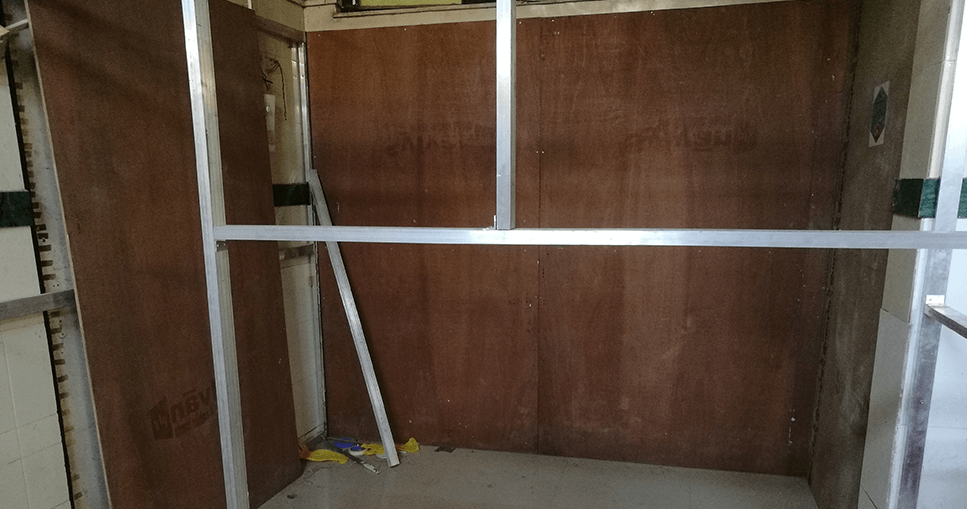

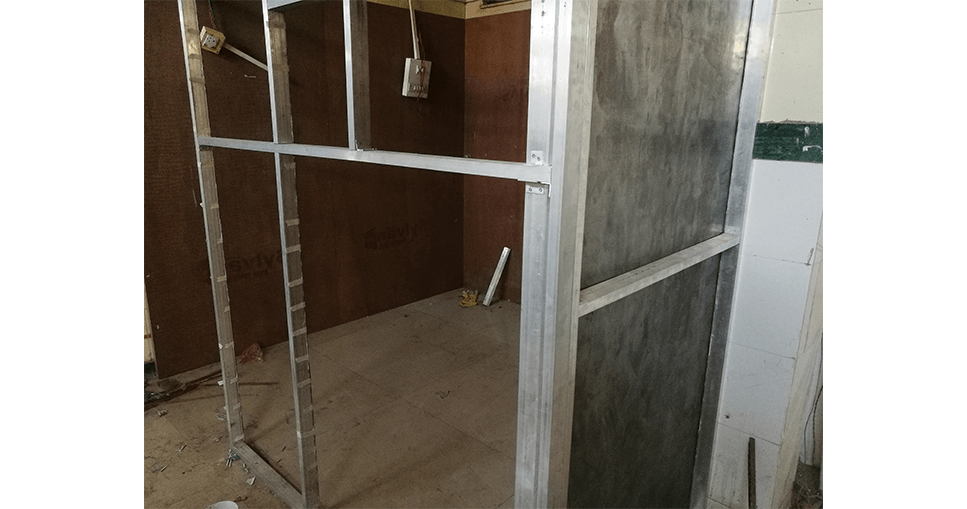

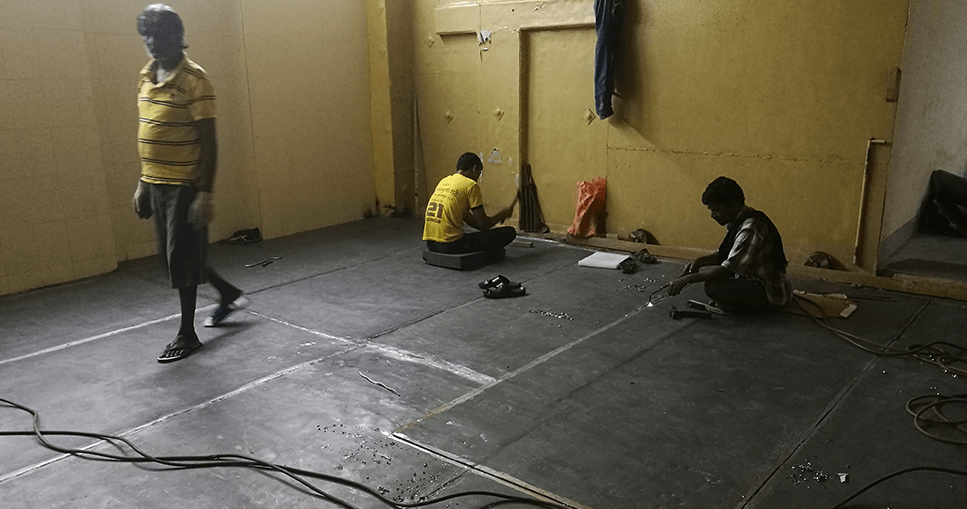

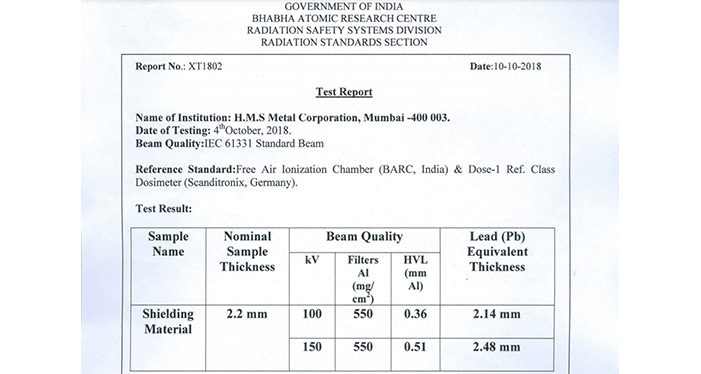

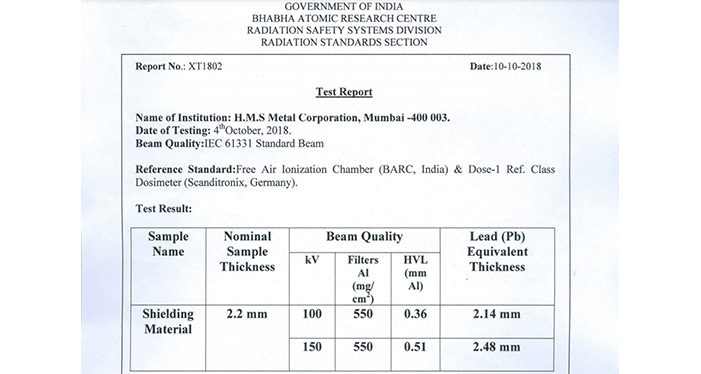

HIGH-QUALITY RADIATION SHIELDING PRODUCTS

Our X-Ray protective products are purpose built by our own expert craftsmen with many years of experience of X-ray shielding. You can be safe in the knowledge that we understand your needs and requirements when it comes to all aspects of radiation protection. We’ve been perfecting our products to the highest level of Radiation shielding working with many professions including architects, hospitals, vets and dental practices.

We pride ourselves on giving a professional approach to supplying radiation protection products to the highest quality available.