57+ Years Of Experience

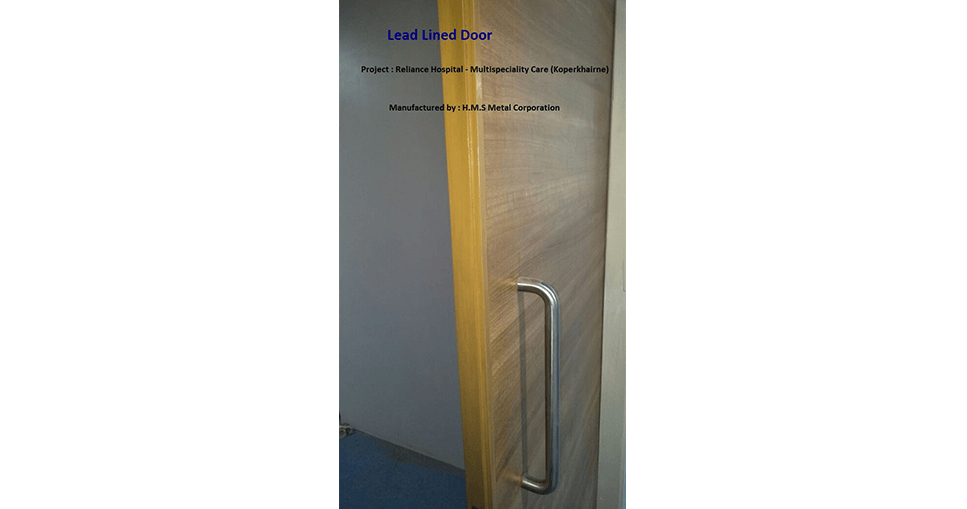

At HMS Metal we find innovative ways to use advanced manufacturing technology to keep costs low while maintaining the highest in quality standards.

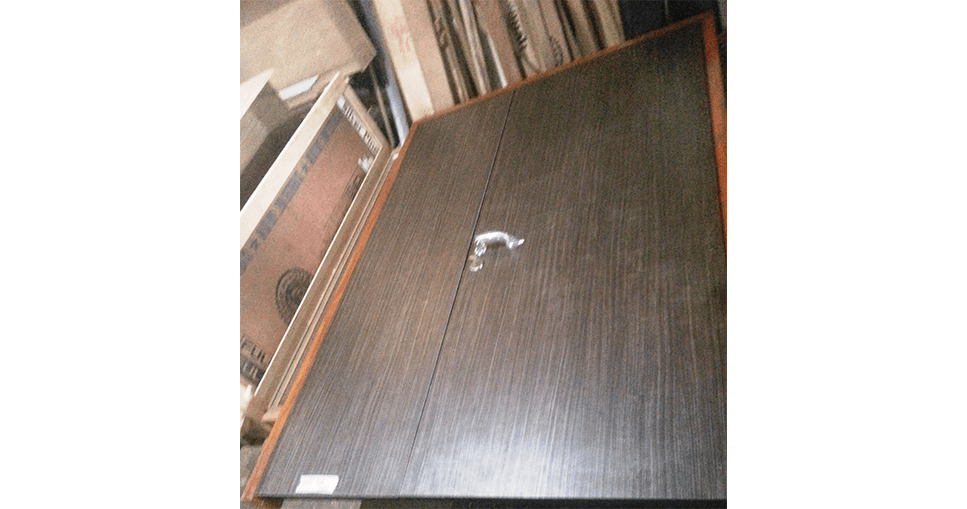

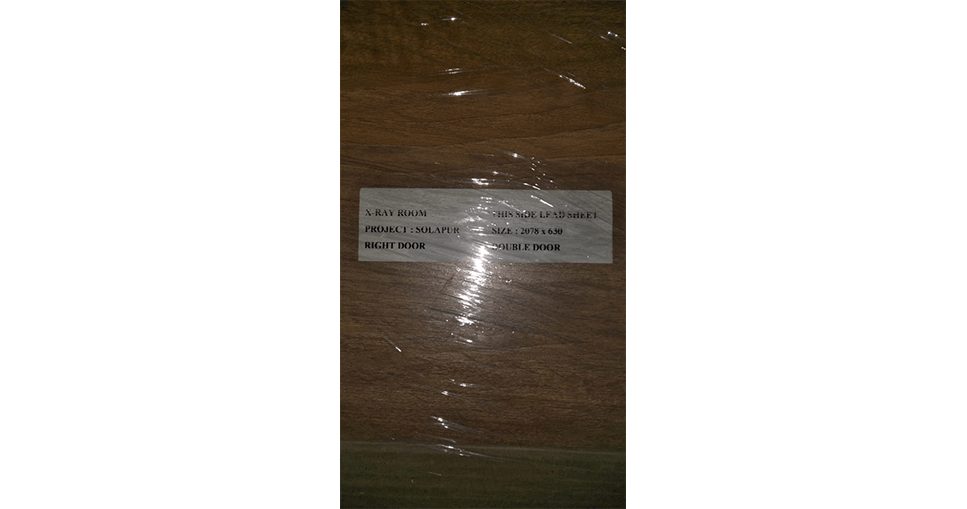

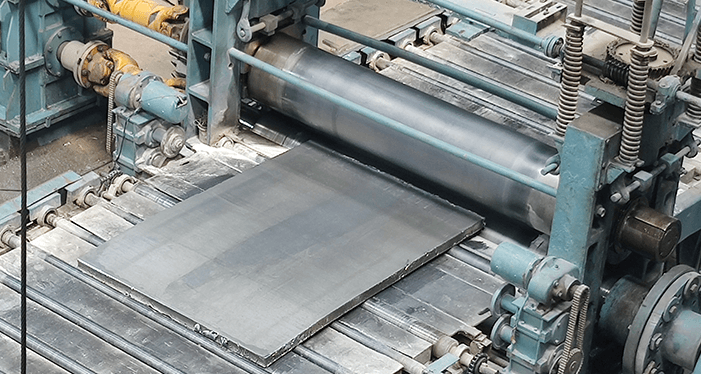

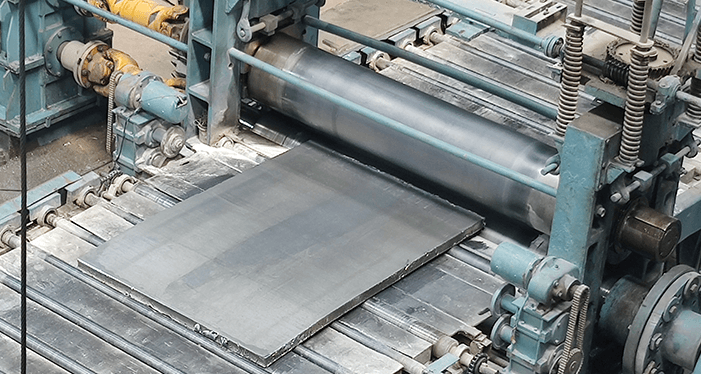

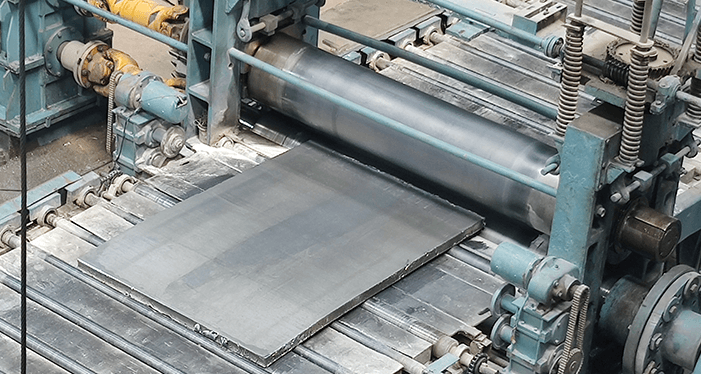

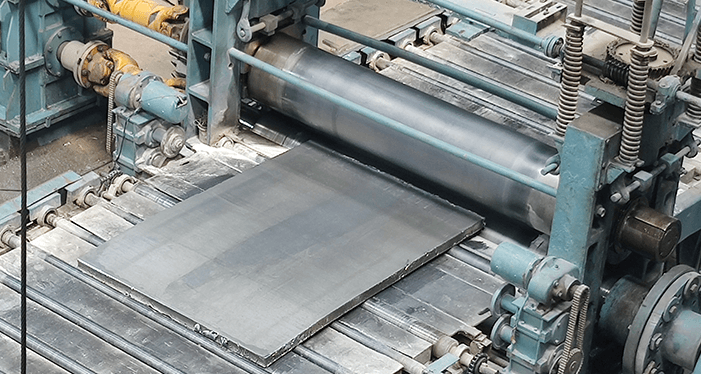

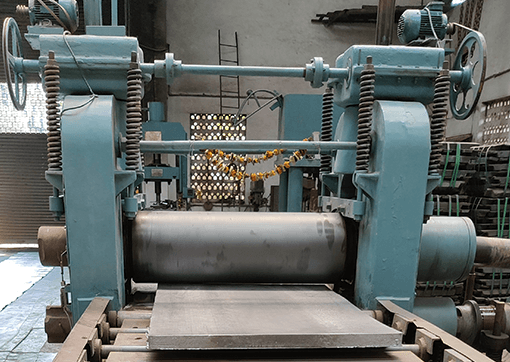

At HMS Metal, our diverse production facilities include capabilities of producing Rolled Lead Sheet, Extruded Lead Pipe/wire/rod/strips/channels/profile, Full in-house facilities for producing Lead Anodes/Bricks/Shots and other products of lead & to custom fabricate any products of lead as per your drawing/sample/photos.

DOWNLOAD BROCHUREOur Facility

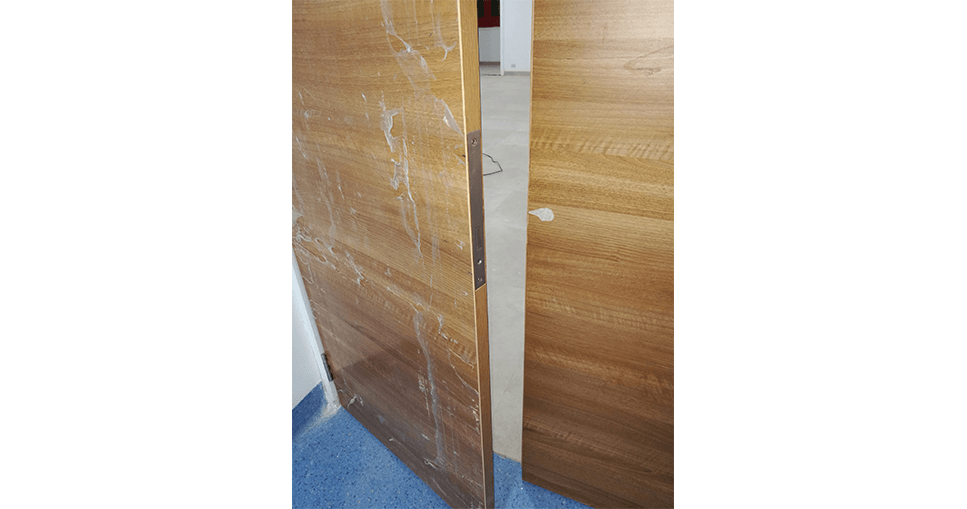

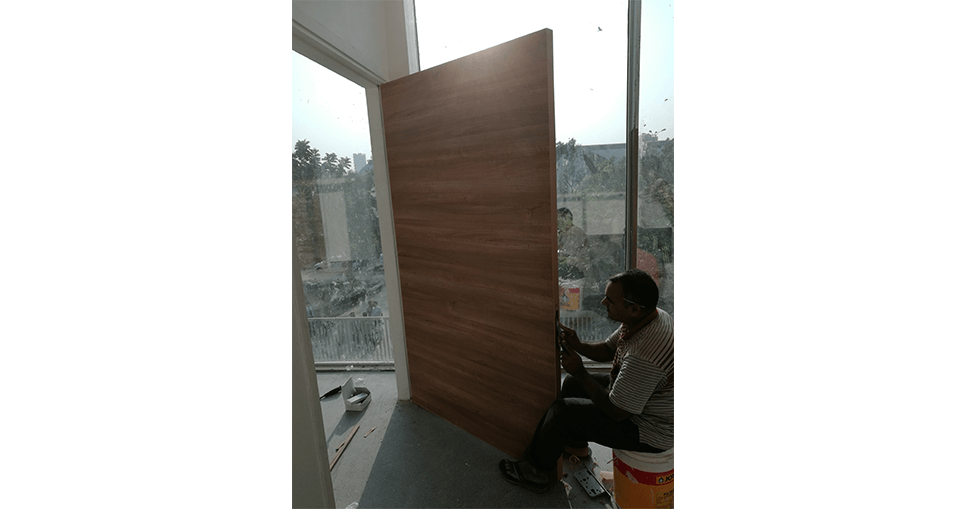

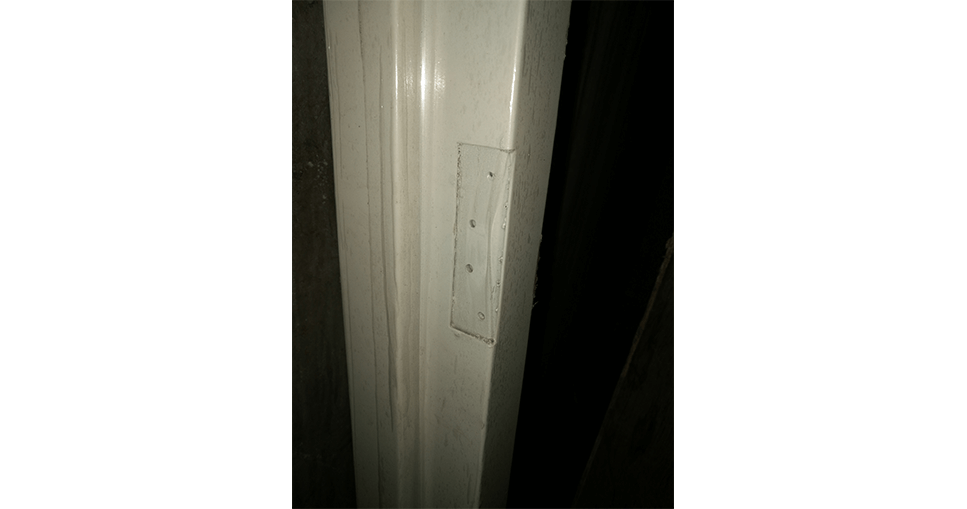

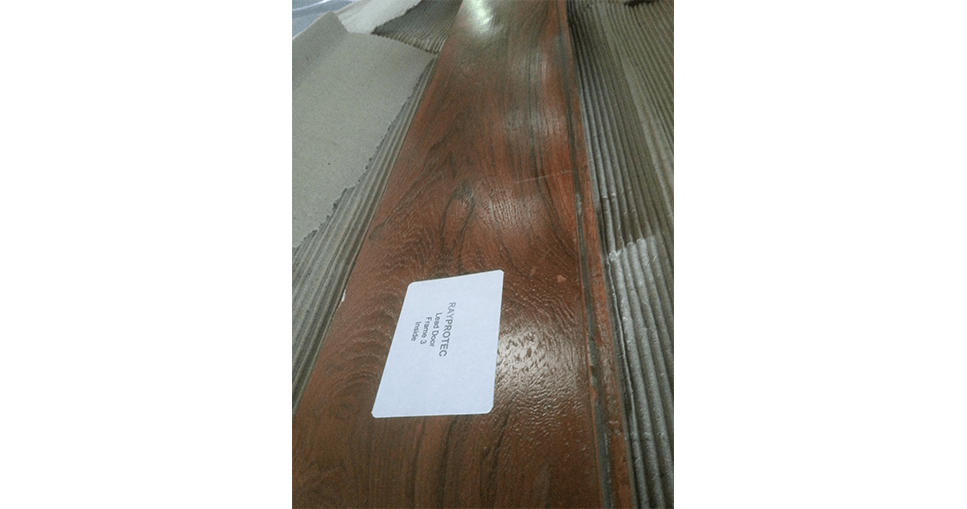

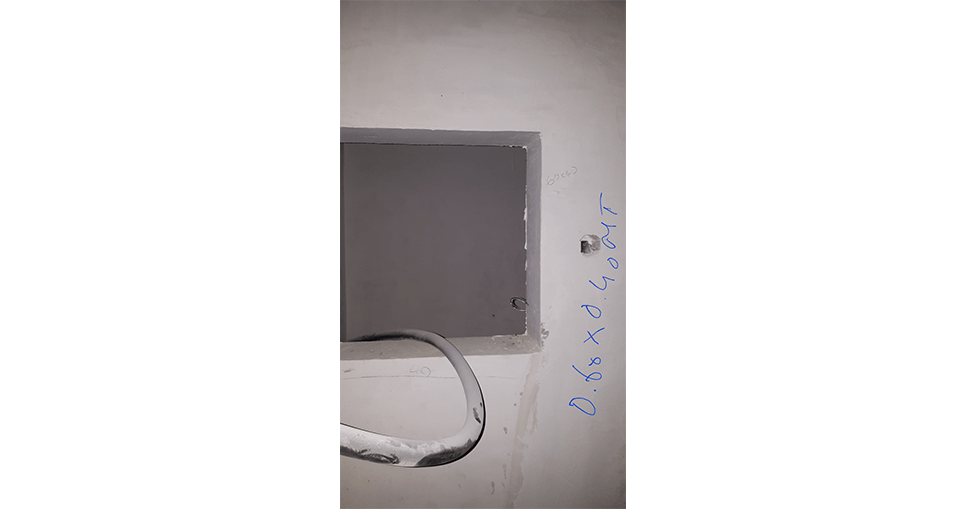

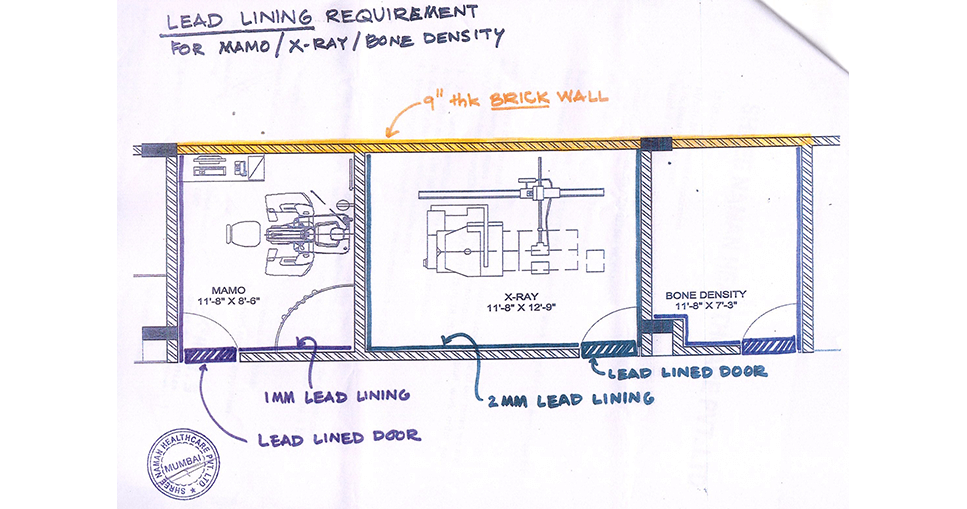

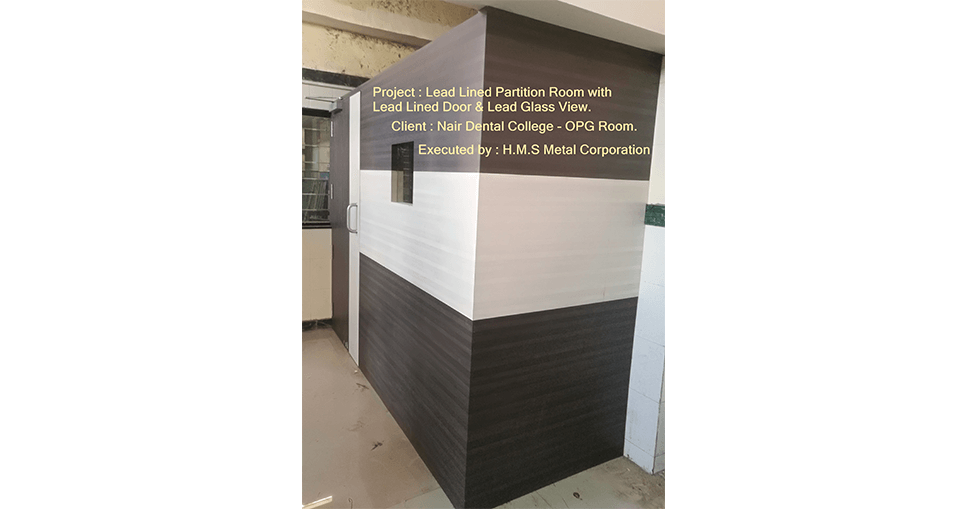

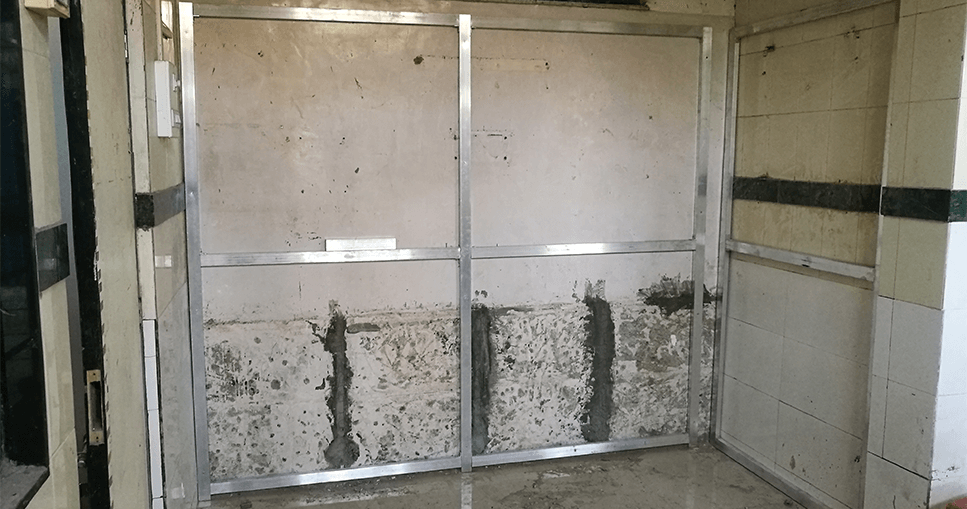

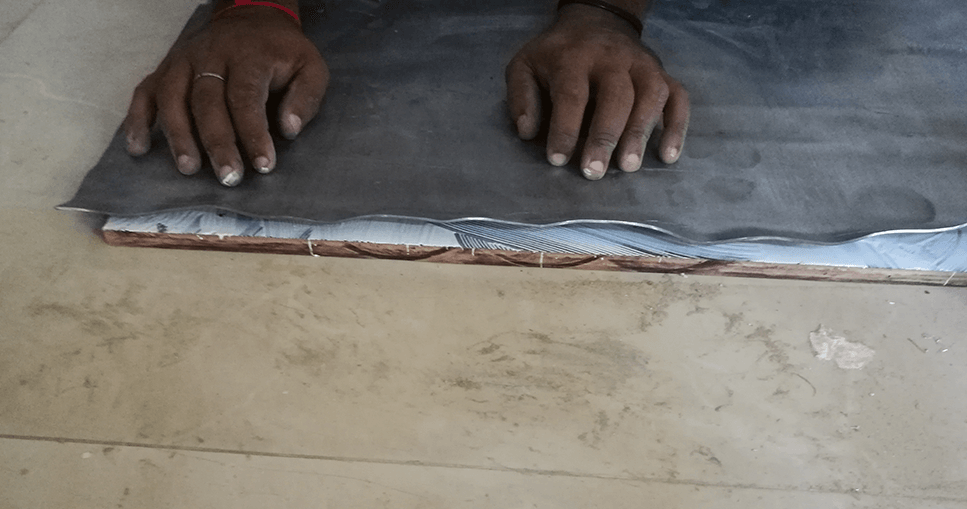

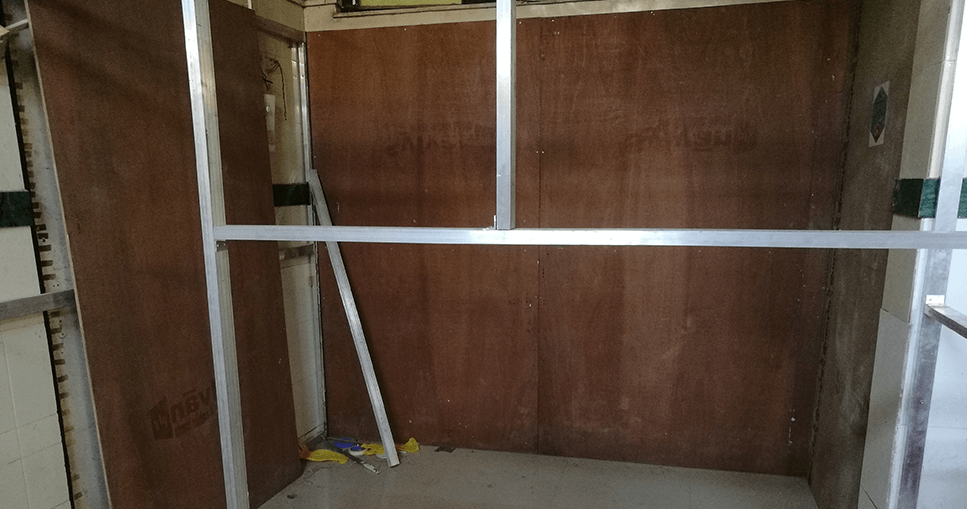

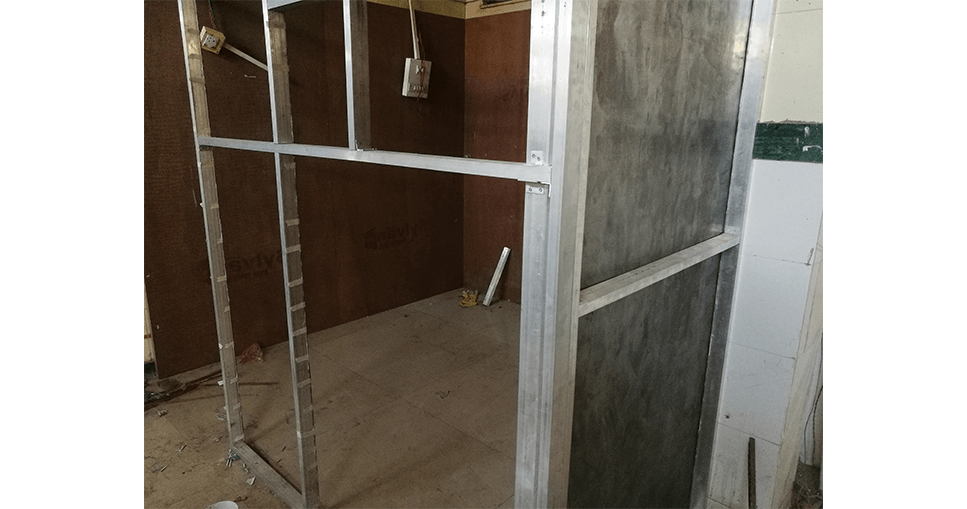

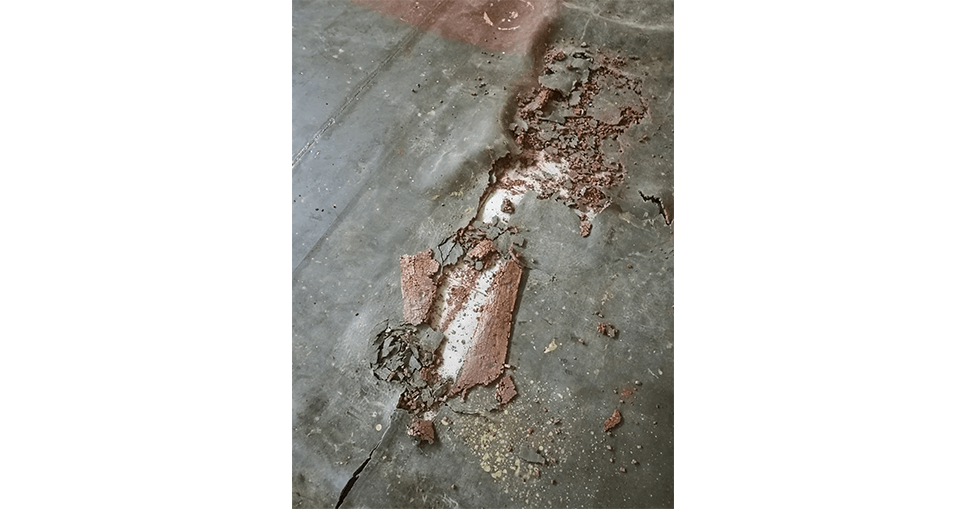

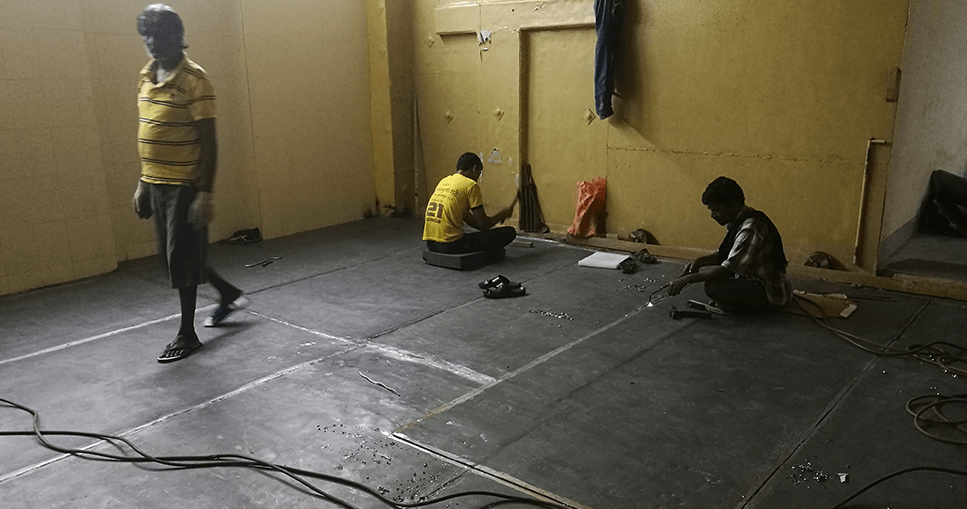

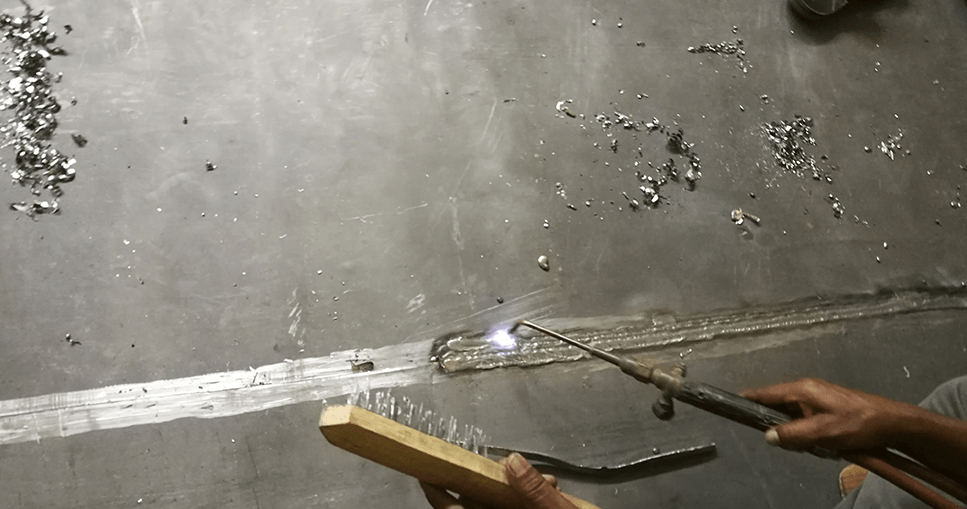

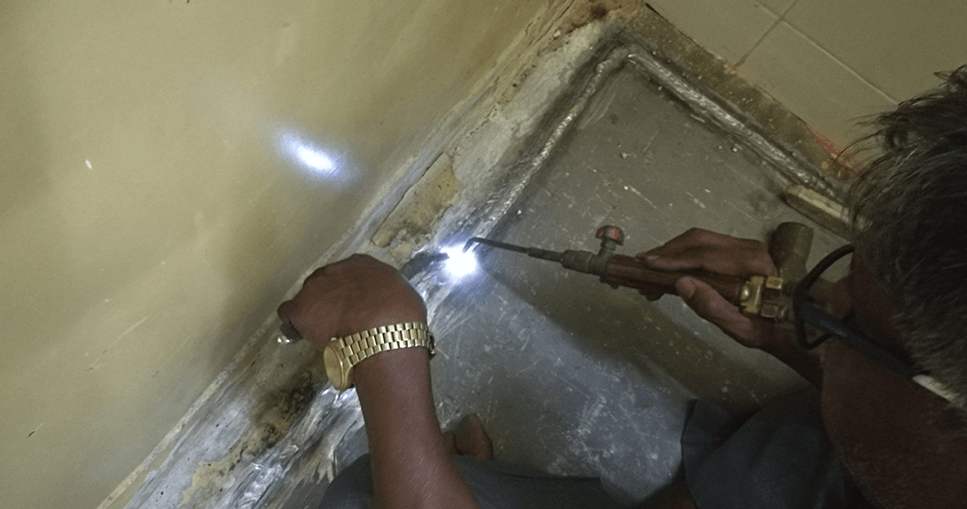

We have full facility for Lead Forming (Bending / Cutting / Drilling / Stamping etc), Lead Burning, Lead Lining, Lead Bonding and Machining

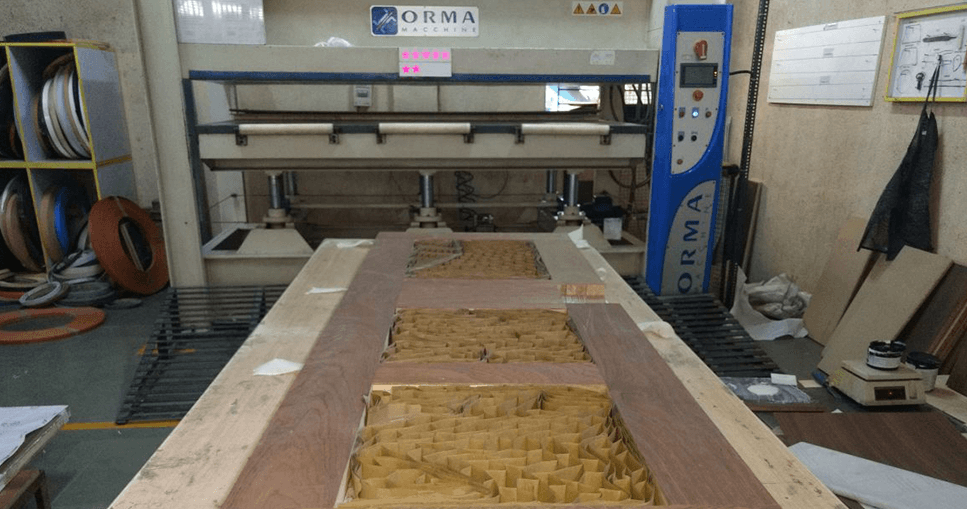

We have numerous dies in stock to help expedite your order and save you money.

Custom Works

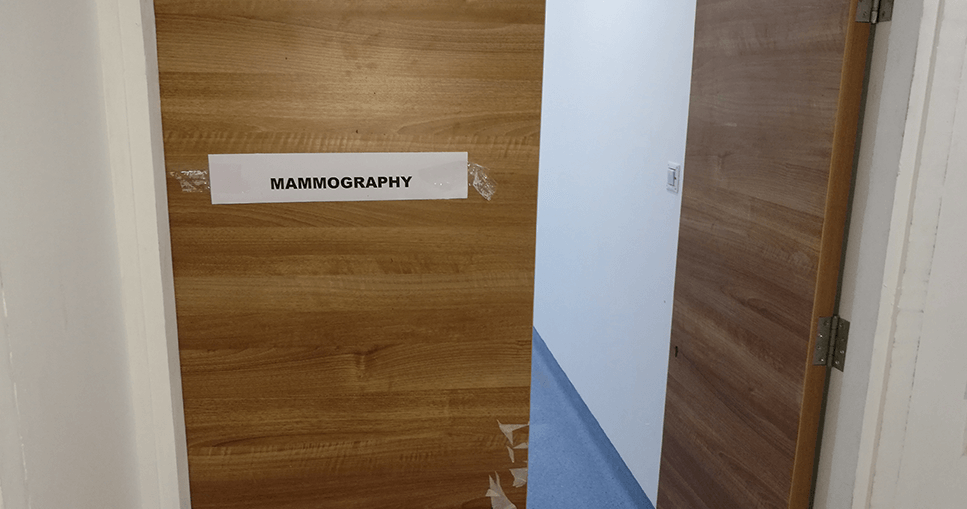

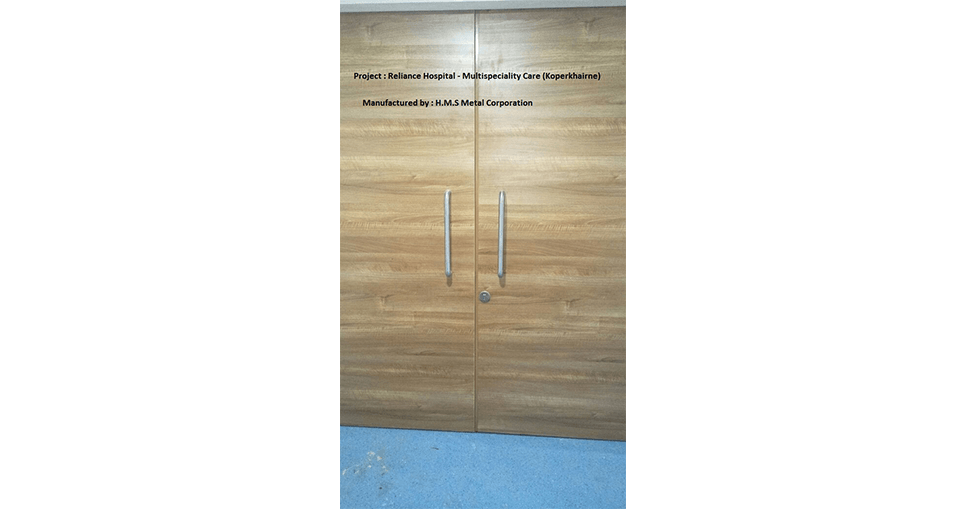

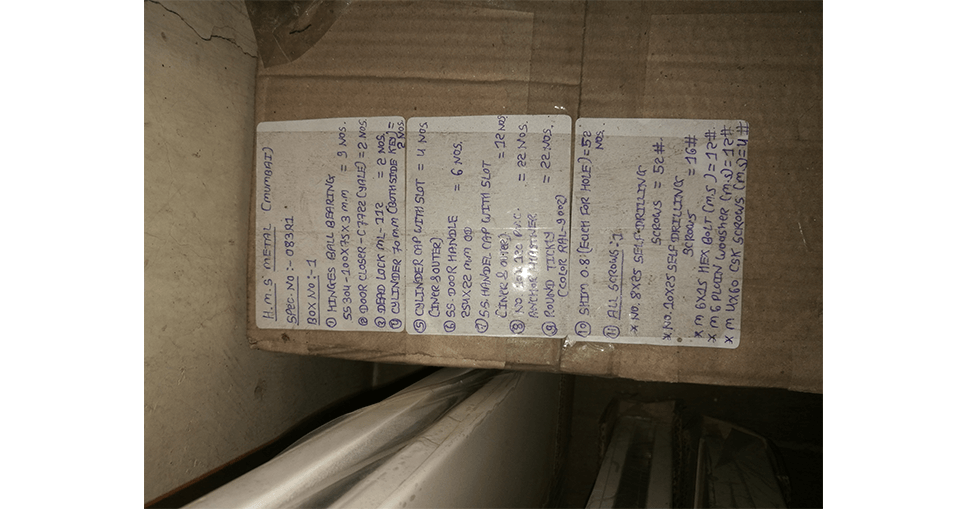

We specialize in custom work be it “Custom Lead Machining” “Custom Lead Assemblies” “Custom lead Products” “Custom Lead Fabrication”- you let us know what you need and we will find a way to get it done.

DOWNLOAD BROCHUREOur Experience

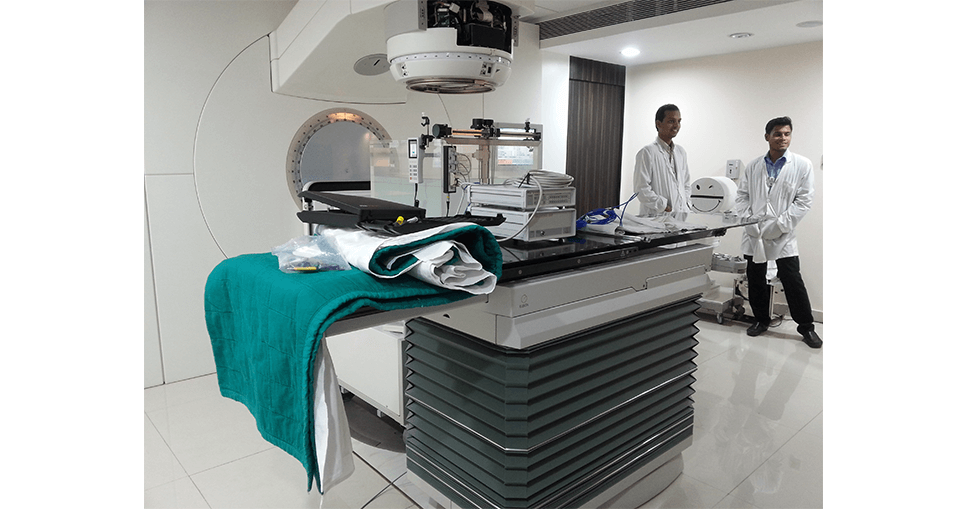

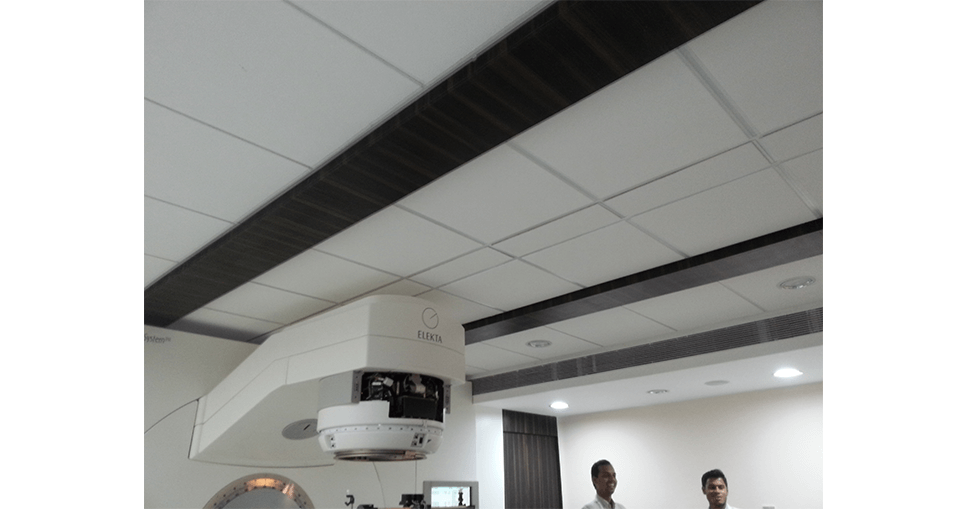

Our facilities combine experienced and passionate with innovative technology to produce quality lead products. We are certified for our manufacturing standards by leading Indian agencies and global classification societies, including the Bhabha Atomic Research Centre, Radiation Safety Systems Division, Radiation Standards Section, Govertment of India.

DOWNLOAD BROCHUREOur Sustainability

As an industry leader, we are committed to supporting and protecting our people, communities and the environment. We are fully focused on responsible production and strive to minimise our environmental footprint by reducing our energy, waste and carbon emissions. Our factory has Solar System Installed which is truly renewable energy source.

DOWNLOAD BROCHUREPROCESS CAPABILITY

- Two melting pots.

- Two Rolling mill producing flat sheet or coil.

- Three Hydraulic extrusion machine for producing Lead Pipe, Rod, Wire & Strip.

- Lifting capacity from 2 cranes.

- Lathe machine, Drill Press Machine.

- Huge Inventory of dies & mould for various casting works.

- Tools for lead burning, lead lining, lead bonding & lead poring.

- Hand Pallet Trolley & other equipment for movement of material and for loading material safely into vehicle.

HEALTH & SAFETY

HMS Metal is committed to the reduction of workplace accidents, to the control of lead-in-blood levels and to the provision of a safe working environment for all employees.

Lead in its metallic state does not present a health risk provided that a few simple precautions are

followed:

- Wear appropriate personal protection equipment, such as safety gloves and boots

- Always wash your hands and forearms as soon as you finish handling Lead and before you do anything else. This applies even when wearing gloves.

- Do not eat, drink or smoke after handling Lead until you have washed your hands.

- When sweeping a Lead storage area, wear a protective dust mask and damp down any dust.

TRULY GLOBAL

Our production facility is based in Mumbai, India which gives us truly global and cost effective manufacturing capability, it also demonstrates the commitment that HMS Metal has made to the regions in which we work, and our customers.

HMS Metal is a highly flexible organisation, willing to work with our customers to optimize solutions. We manufacture as per Customer required size, quantity, alloy type, Material Standard such as ASTM, DIN, IS, BS ANSI etc.

We offer a range of standalone related services for manufacturing our entire Production range.