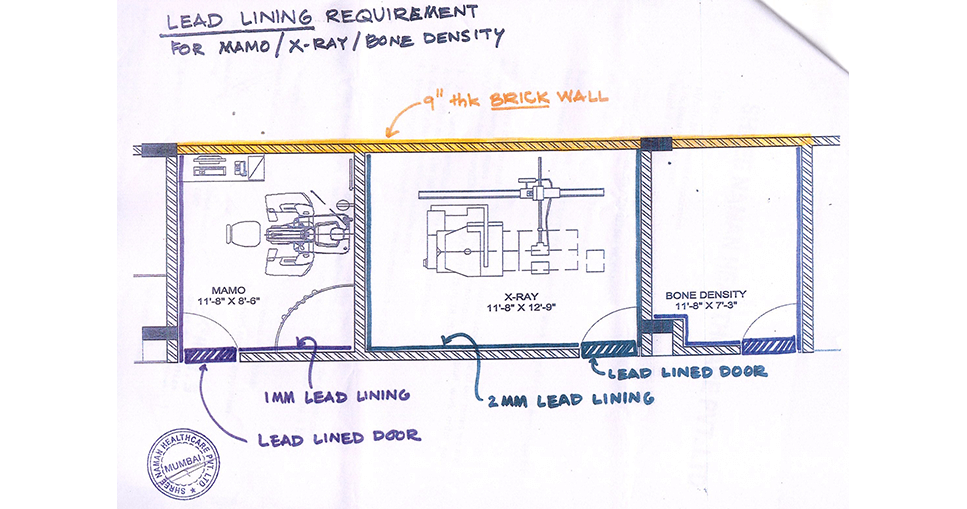

Structural Radiation Shielding we offer lead backed plasterboards or plywood and complete range of X-ray Room or Imaging Room shielding products and installation services.

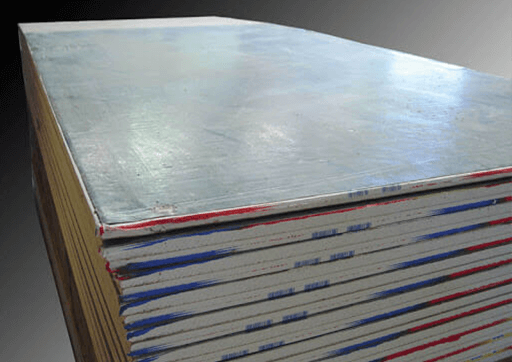

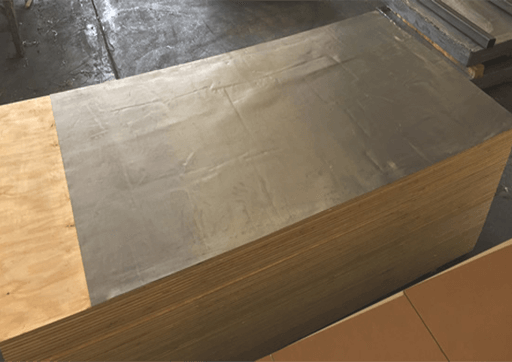

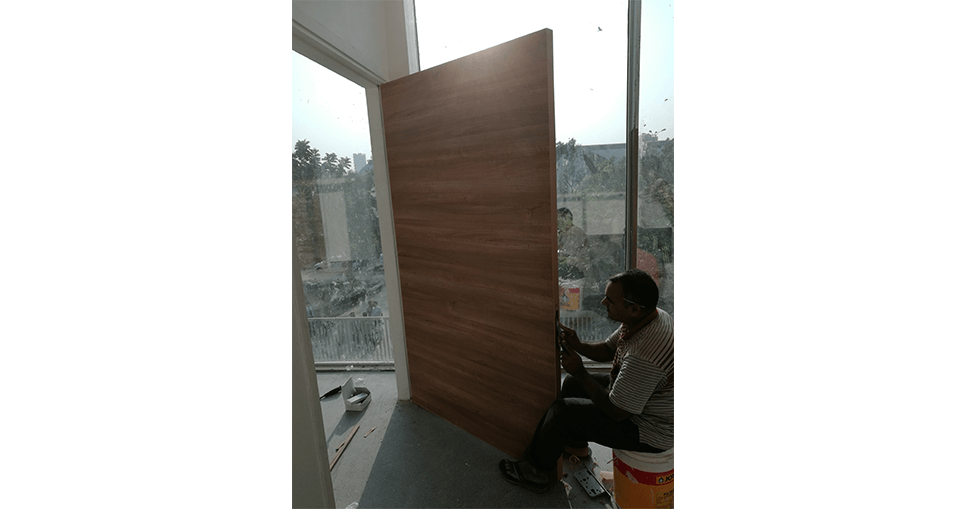

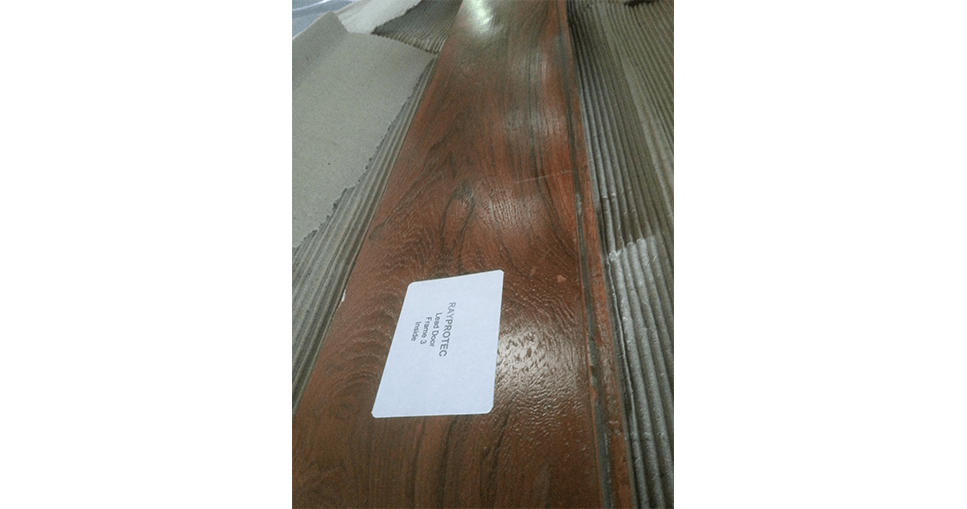

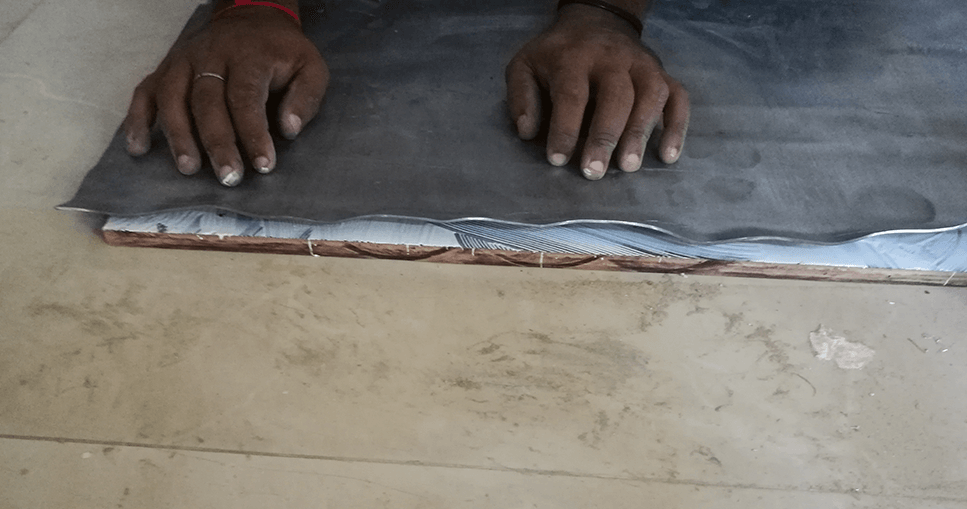

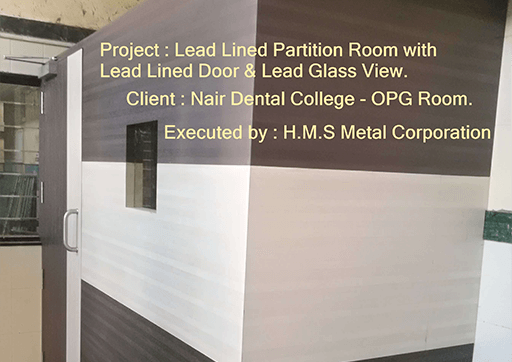

Wall, Ceiling and Floor Panels – X-ray protective lead lined panels and partitions and lead bricks.

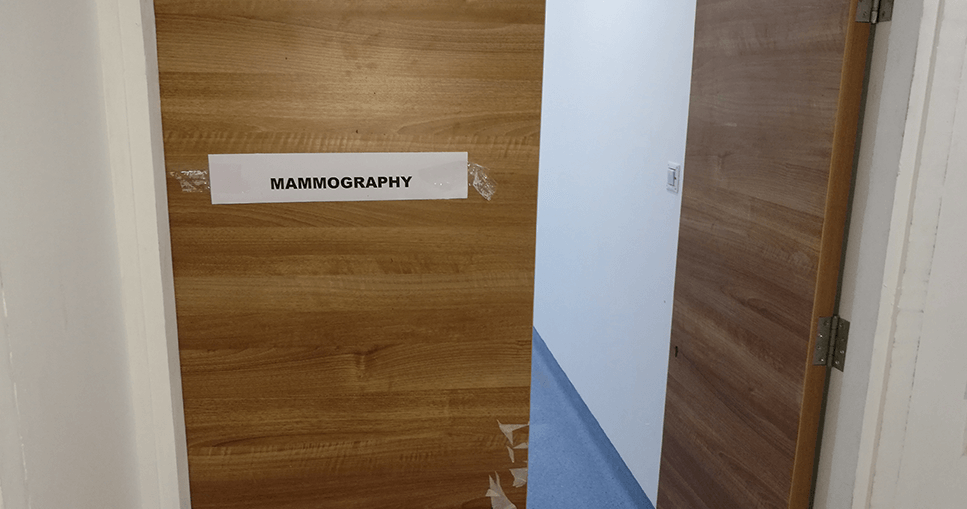

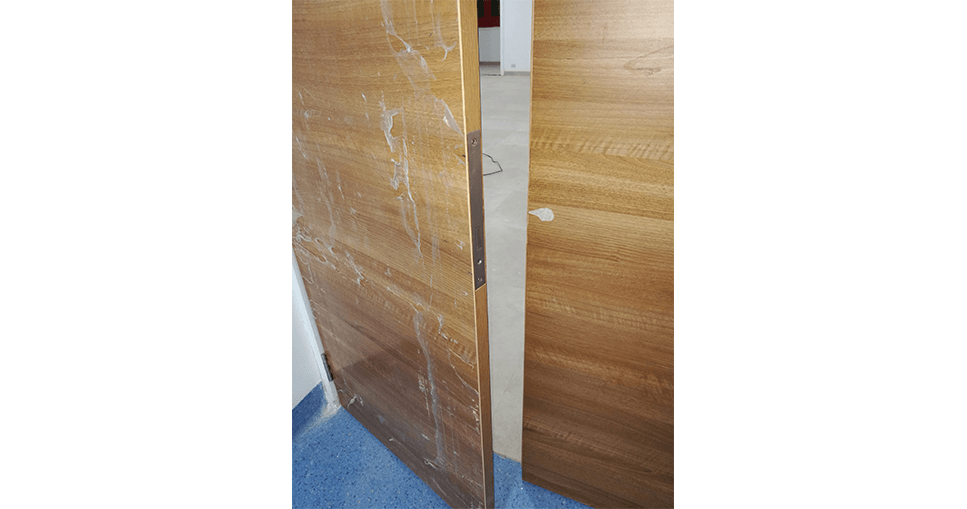

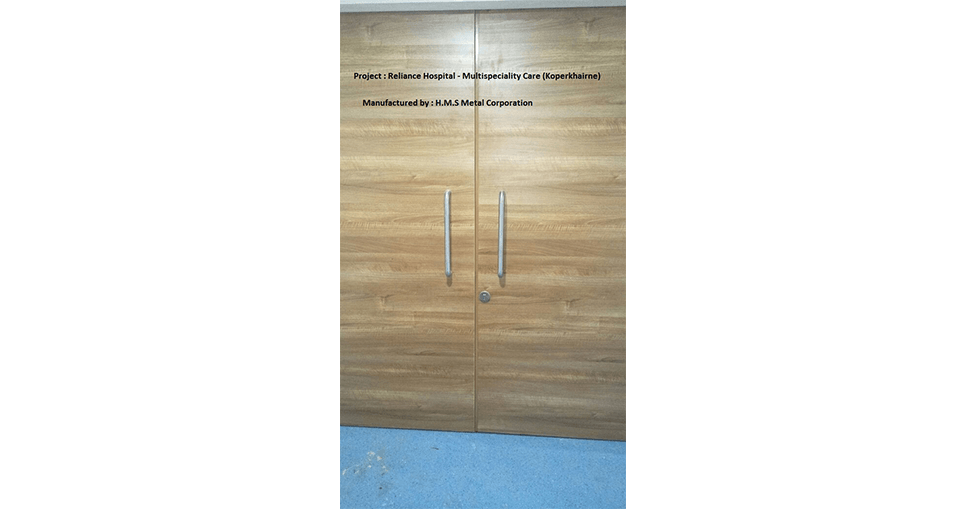

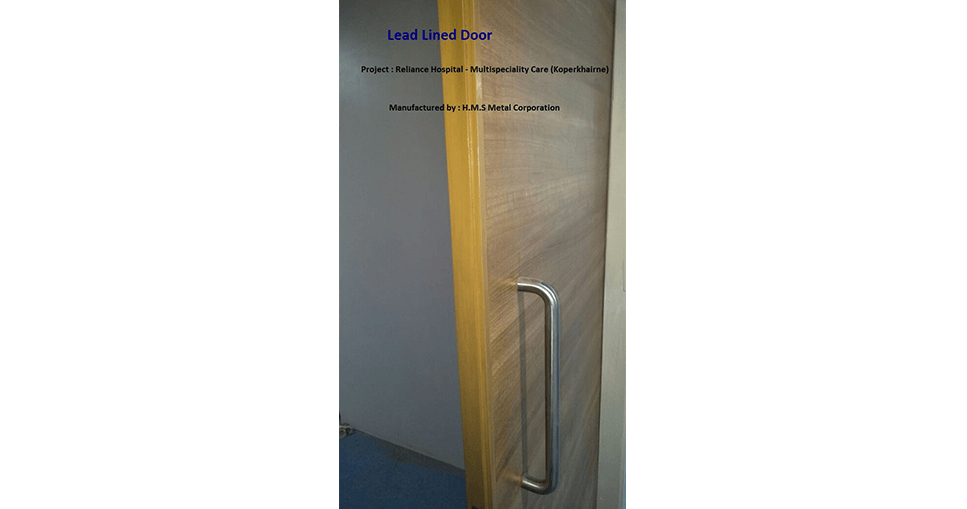

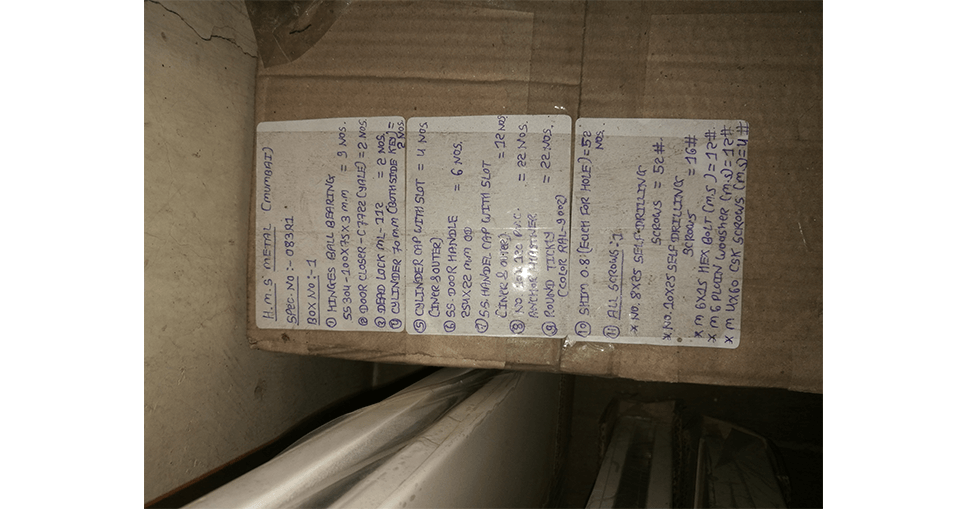

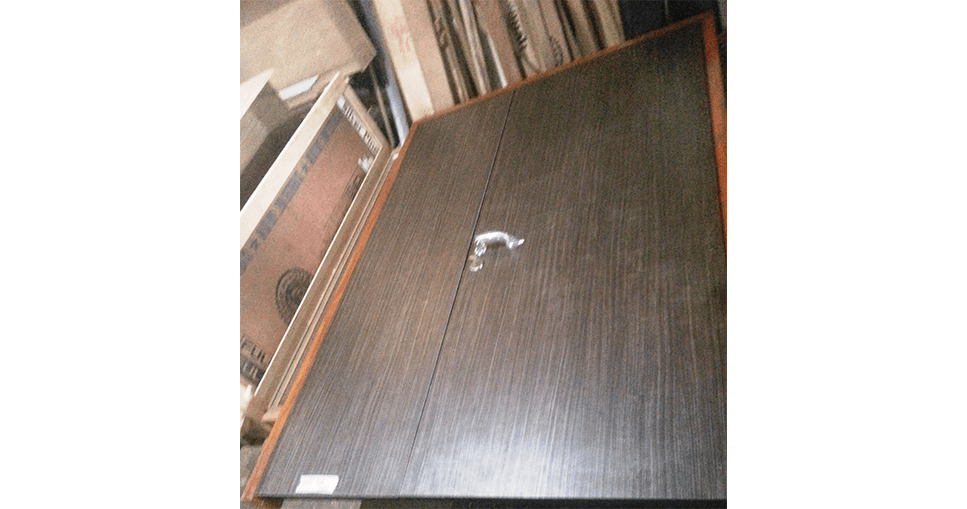

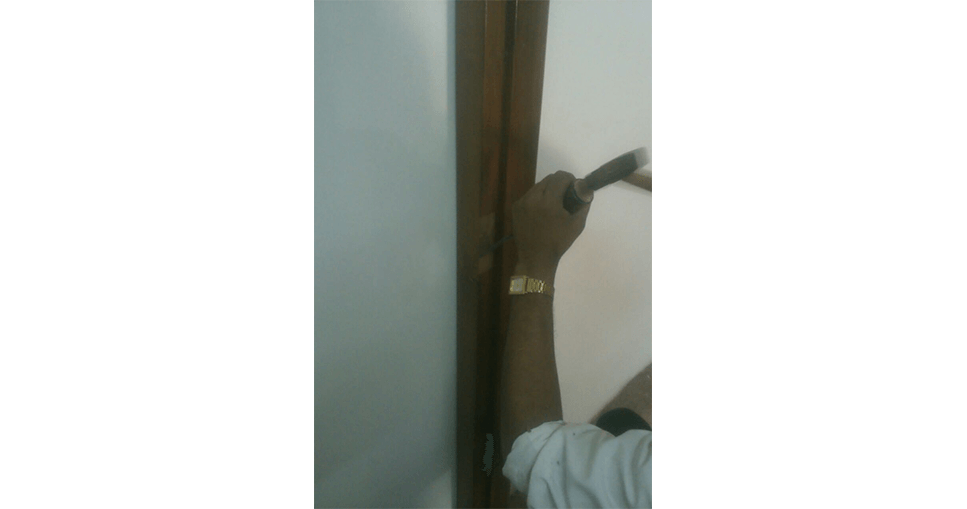

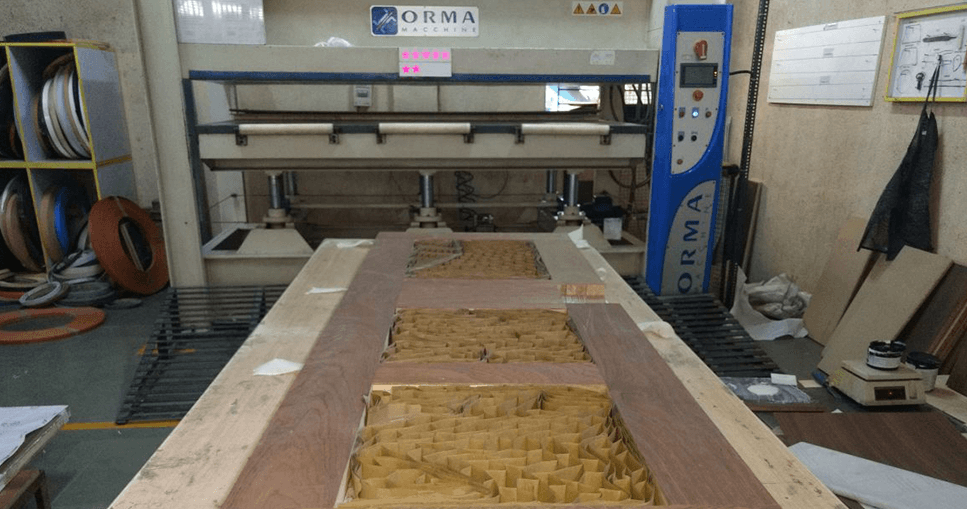

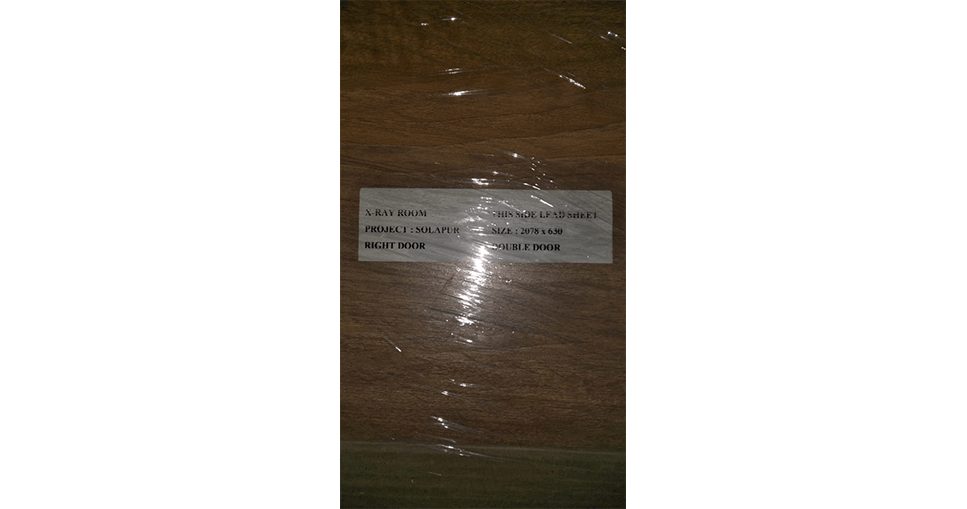

Door Sets – X-ray protective lead lined door sets, including Hinged Wooden Doors and Door Hardware.

Observation Windows – X-ray protective observation windows, including Lead Glass.

Screens – X-ray protective screens, including mobile screens and movable shield.

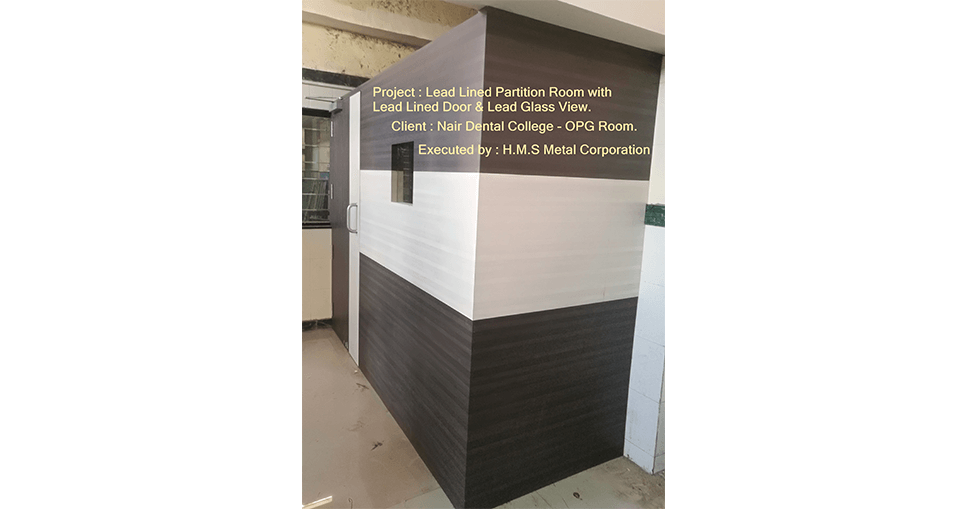

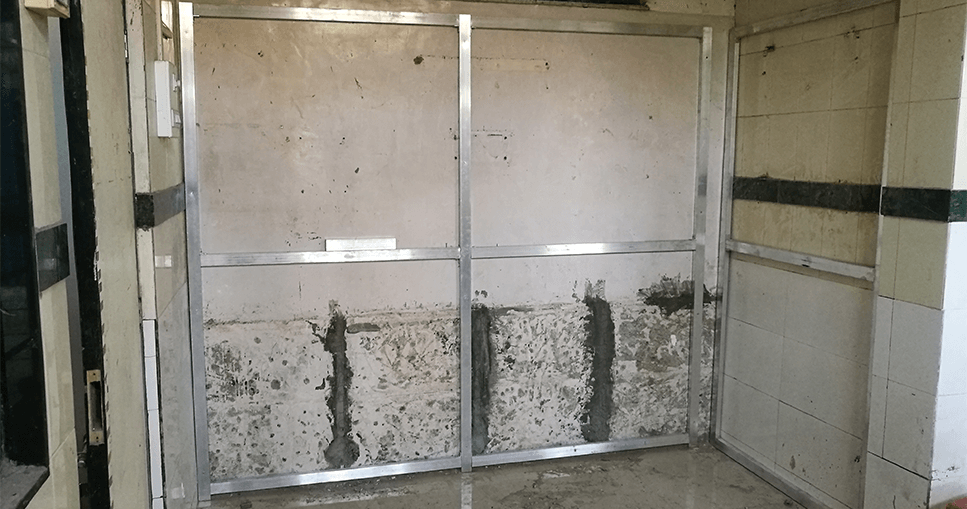

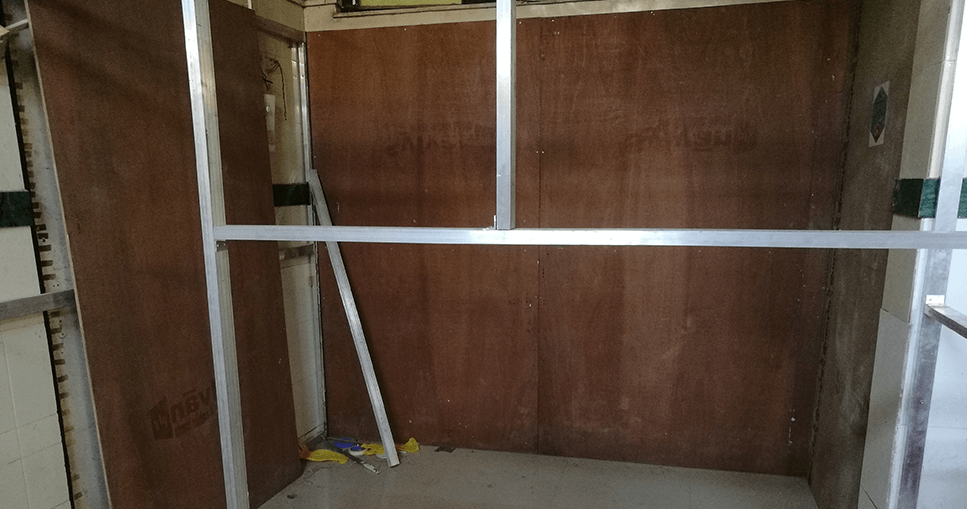

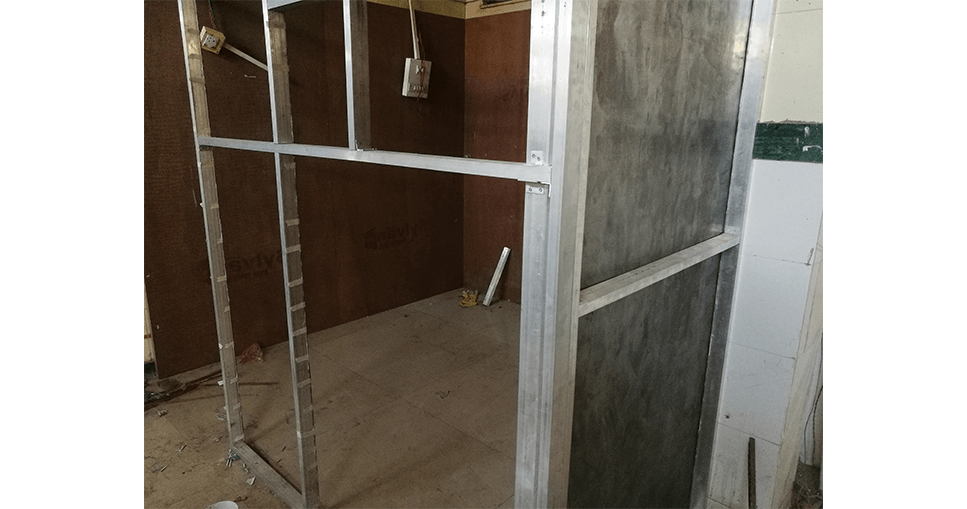

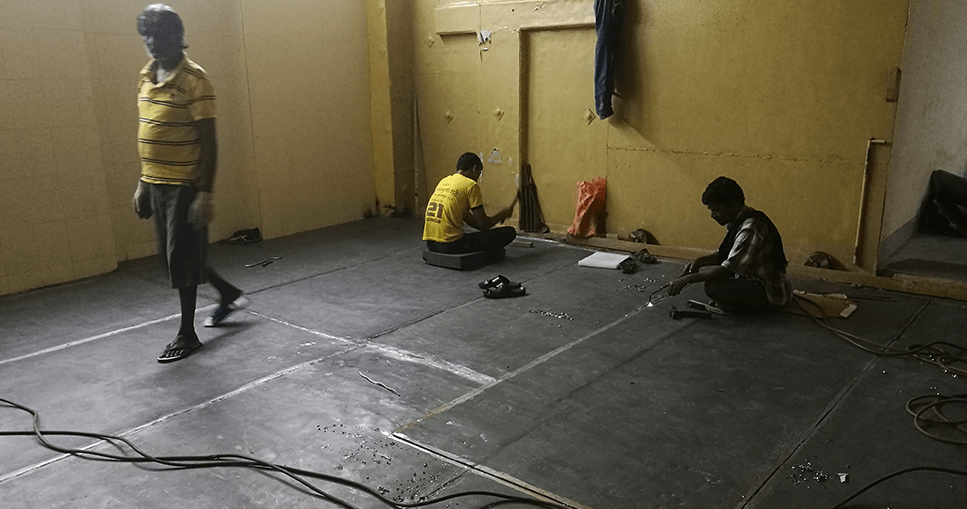

Room Construction – Lead Lined Partition Room with support of plywood or gypsum is constructed. We have successfully completed Lead Partition Room in Nair Dental College where we have used plywood for lead support.

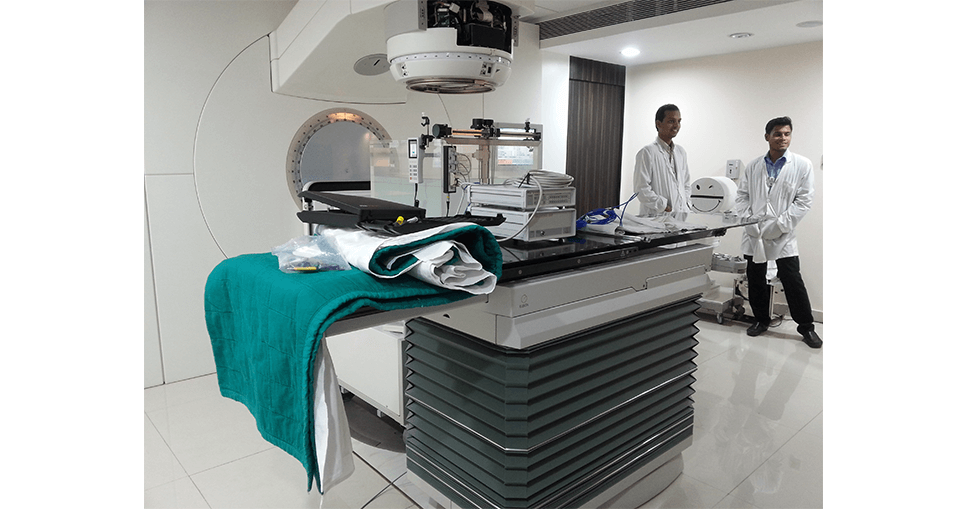

HMS Metal specializes in lead shielding products for government, commercial, industrial and medical applications.

HMS Metal provides unprecedented support for architects, designers, contractors or private customers to help facilitate the correct lead shielding needed for your specific application.

This requires protective barriers within walls, floors, ceilings, entrance doors, windows and for the staff working in a diagnostic x-ray room.

PRODUCT ATTRIBUTES

Advantages of installing plywood/gypsum board with lead lining

- Provides effective floor-to-ceiling radiation protection

- Offers design flexibility for use in walls, floors, and ceilings

- Eliminates the risk of radiation leakage when properly installed

- Available in varying thicknesses to meet a wide range of shielding requirements

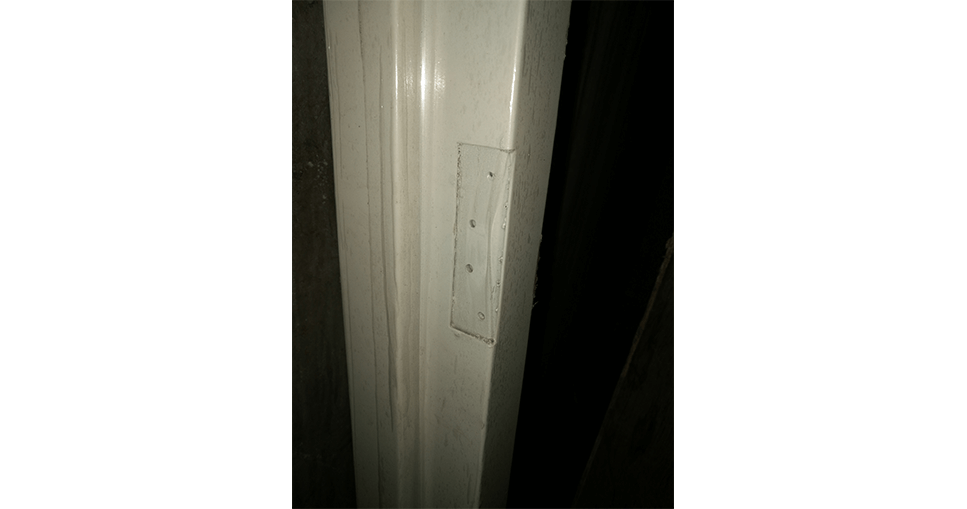

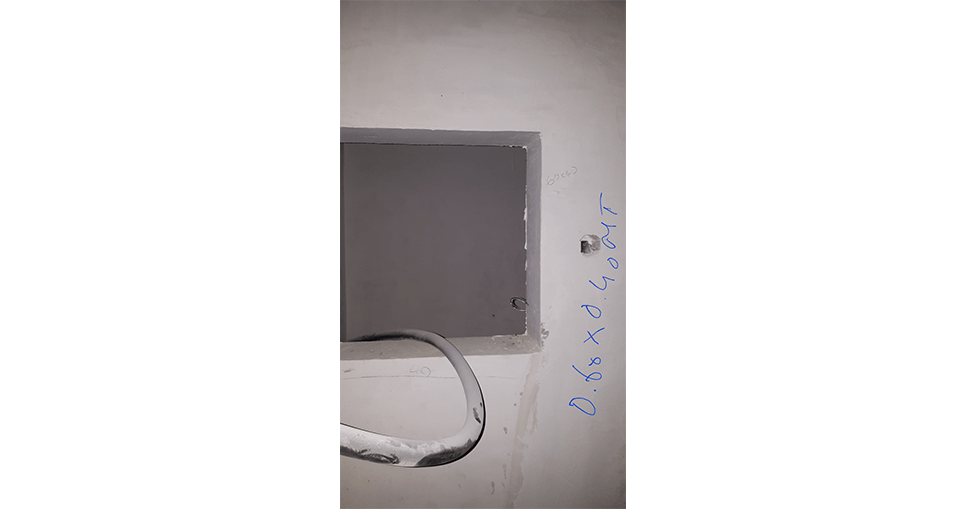

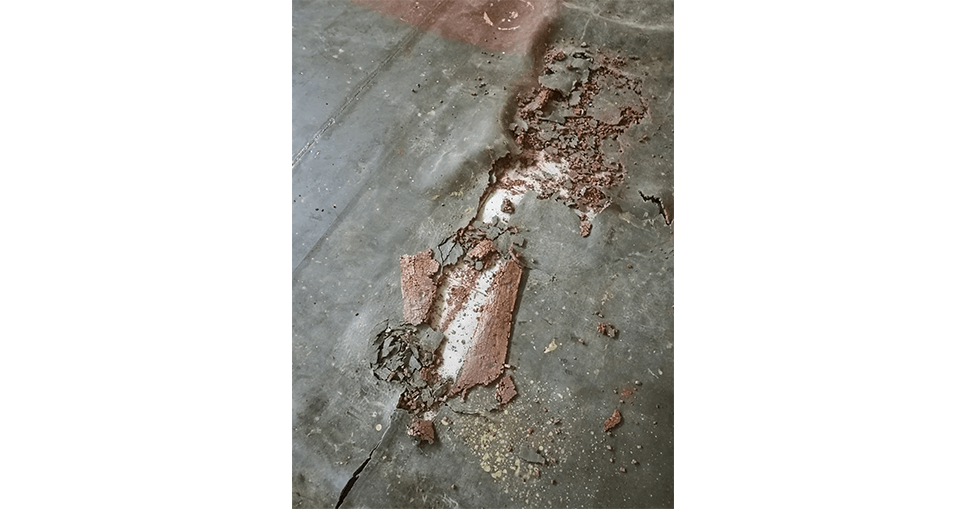

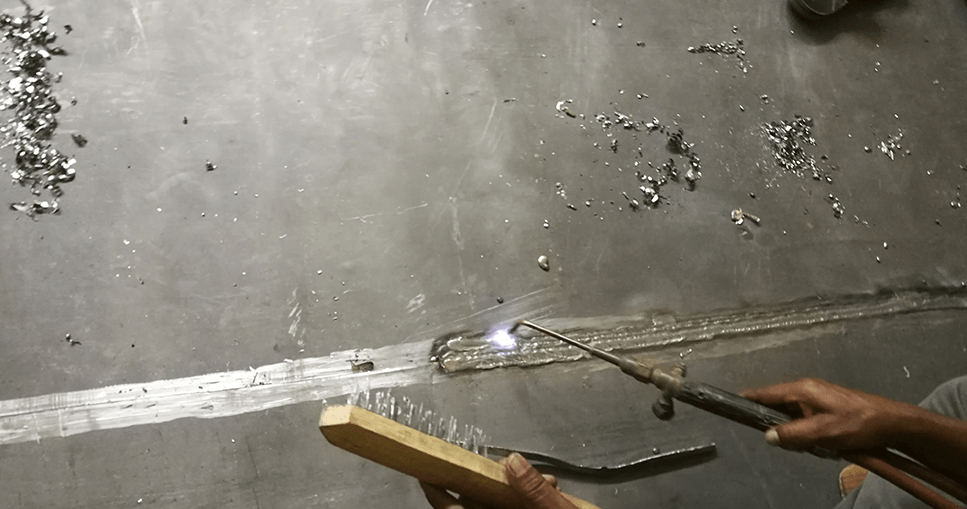

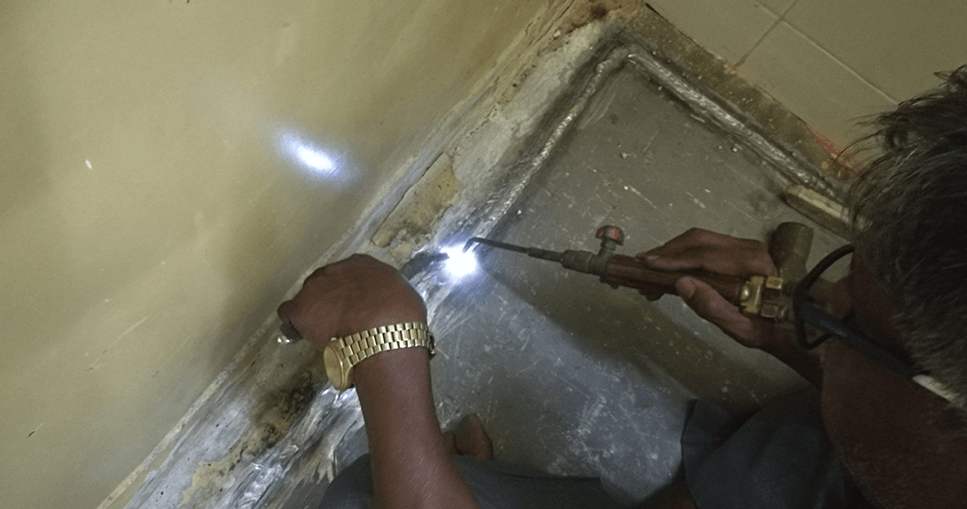

Cutouts & Penetrations

When installing lead lined plywood or drywall (lead lined sheetrock, lead lined gypsum), all cut outs, seams and penetrations will require sheet lead or lead plate to ensure continuous shielding throughout the room. Proper installation of additional lead wherever penetrations are created will eliminate potential leaks and ensure total protection.

Additional sheet lead can be supplied to easily allow for the proper shielding of penetrations such as receptacles, light switches, ducts and telephone/data cables.

Providing Sufficient Shielding from Different Types of Radiation

Different types of radiation are emitted with different levels of energy behind them, but all are caused by unstable atoms. The greater the energy of the radiation, the greater the level of shielding required to safely shield against it. When proper shielding is not provided, radiation can cause burns on the skin and at high levels, puts people at risk of radiation sickness.

- Alpha radiation (α) is comprised of very weak particles that are unable to travel more than a few centimeters when airborne and therefore requires little shielding. In fact, the outermost layer of human skin is actually enough to protect against this type of radiation.

- Beta radiation (β) particles can travel farther because of its small mass and requires more protection, such as heavy clothing or a thick piece of plastic, wood or aluminum. Certain beta radiation particles can penetrate and burn the skin.

- Gamma radiation (γ) consists of photon energy, not particles, and can travel far distances. Protection from gamma radiation requires the use of dense materials such as lead to provide effective radiation shielding. Gamma rays are biologically hazardous and can cause tissue, bone and organ damage if proper protection is not used during long periods of exposure.

- X-ray radiation are considerably stronger and have a longer wavelength than other types of radiation and requires thick, dense shielding, such as lead. Because prolonged x-ray radiation exposure can cause DNA mutations, it is classified as a carcinogen.

Important Factors for Determining Your Radiation Shielding Requirements

Radiation shielding is available in varying degrees ranging from protective vests and leaded glass barriers to rooms constructed with lead lined drywall, doors and windows. High energy radiation applications and those involving nuclear power may also require the use of lead bricks for additional shielding protection.

There are various lead shielding considerations including radiation type, equipment orientation, workload and occupancy but exposure time and distance are the most important in calculating the level of protection required for your application.

Using Exposure Time to Determine Radiation Shielding Requirements

Obviously, the longer the time spent near a source of radiation, the greater the level of exposure. Even the briefest direct exposure to gamma and x-ray radiation can be extremely hazardous, and unprotected exposure to any sort of radiation for any length of time should be avoided. Extended indirect exposure to radiation (e.g. an x-ray technician who is in a separate, but nearby, room from the x-ray source for several hours a day) also requires shielding to keep personnel safe.

The longer one must be exposed-directly or indirectly-to radiation, the greater the level of shielding required. For medical and dental patients, for example, the length of direct exposure to x-rays is very brief, therefore a lead vest is sufficient for safe shielding. However, because an x-ray technician is indirectly exposed to radiation for extended periods, stronger, more substantial shielding is necessary.

Measuring the Distance from the Radiation Source to Calculate Protection Requirements

The greater the distance from a source of radiation, the lower the level of exposure. Doubling the distance from the source reduces the level of exposure by a factor of four (i.e. at ten feet from the source, radiation exposure will be 1/4 the level present at five feet). Therefore, the closer to the source of radiation one must be, the more protection is required.

Minimum safe distances are affected by the type of alpha, gamma, x-ray or beta radiation encountered. Alpha and beta particles lack the energy to travel far, while gamma radiation is powerful enough to travel long distances. Always consult with a radiation physicist to ensure you are using the correct calculations to determine your radiation shielding requirements.

Delivery Time

Since Lead partition are made to order, ask for delivery time while placing the order.

Customer Experience

At HMS Metal the relationship we establish doesn’t end when the sale is final. In fact, we think its only the beginning. HMS Metal is looking to the future by putting you on receiving end of unmatched experience and customer service. Our desire is to be your long term single source solution for your next facility, expansion or department upgrade.

Note

The amount of lead required in lead partition must be determined by a licensed radiation shielding physicist.