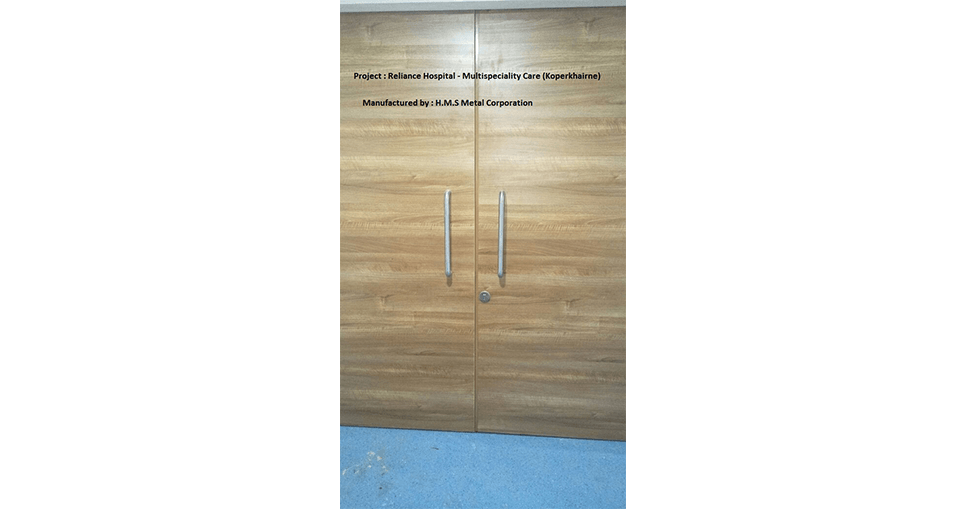

We are the GLOBAL LEADER in MANUFACTURING LEAD SHEET for hospitals, clinics & chemical industries with stringent quality and delivery requirements to over 700 domestic customers and over 85 international customers (in around 21 Countries). Our enviable clientele is the testimony of our product quality and service.

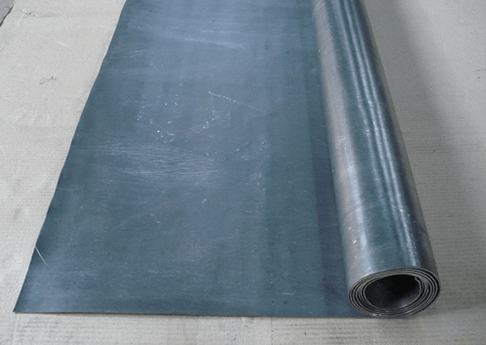

Our CE Marked & AERB approved products are manufactured in accordance to BS EN 12588 and ISO 9001:2015 compliant quality management systems. The rigorous quality checks throughout the entire process from manufacture to despatch make sure our lead sheet is free from dross, oxide inclusions, scale, laminations, blisters, and cracks.

Our Lead Sheet is supplied directly to end users, OEM, Contractors & Traders.

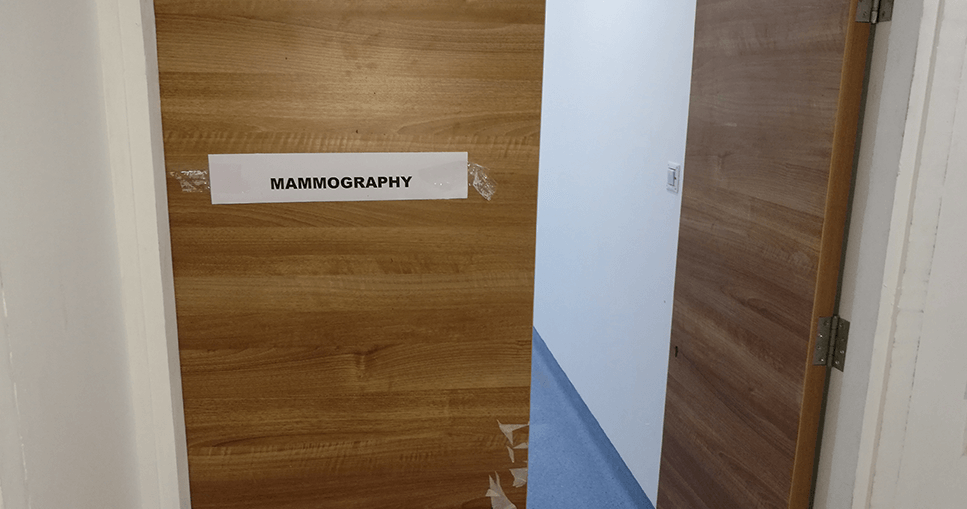

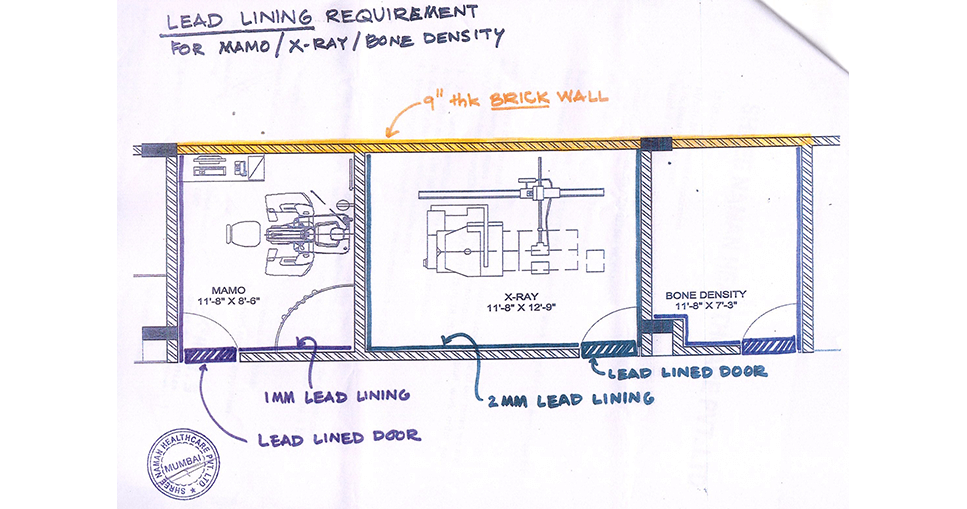

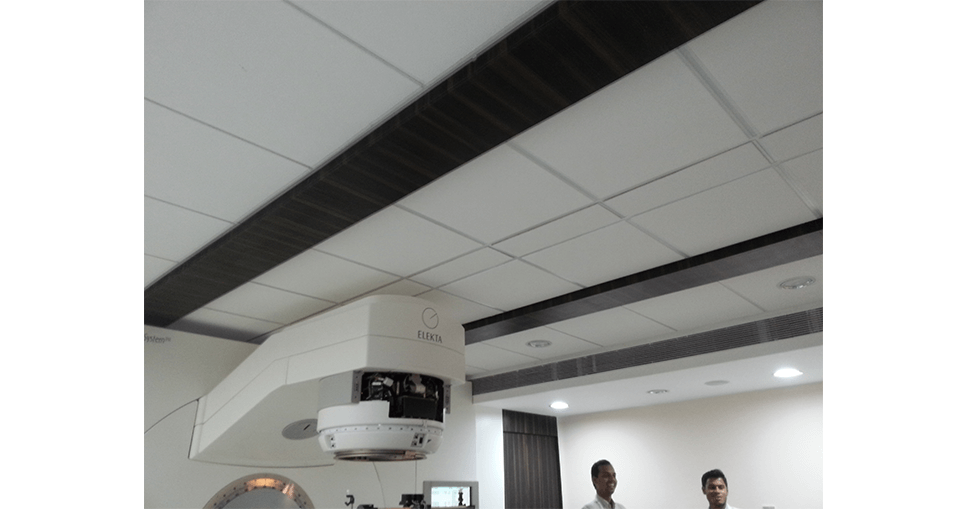

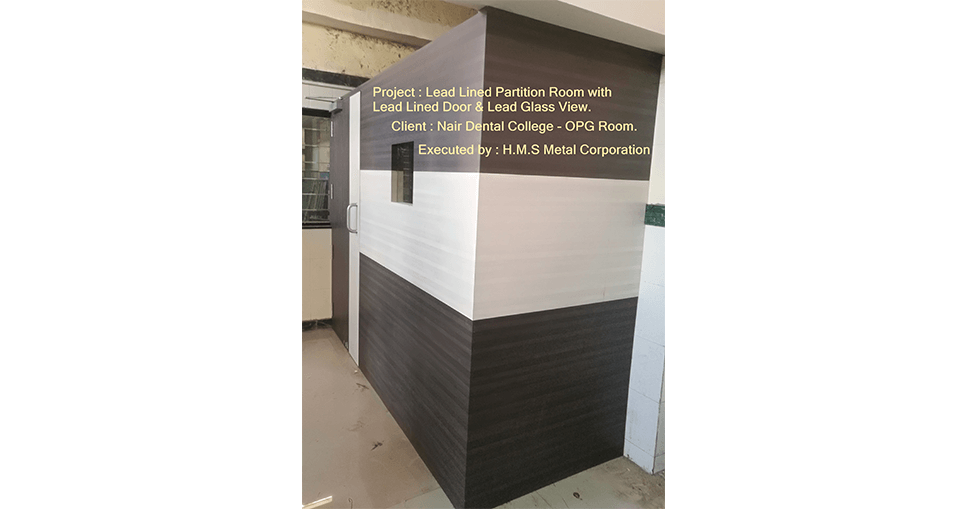

Lead Sheet is preferred material for Medical Radiation Shielding, Chemical Corrosion protection and for Acoustic insulation for used as a sound barrier material.

PRODUCT ATTRIBUTES

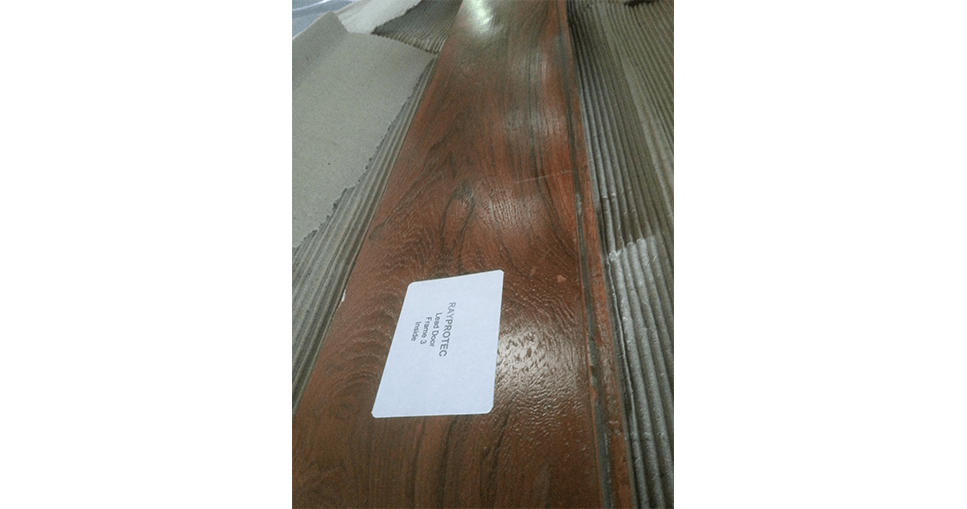

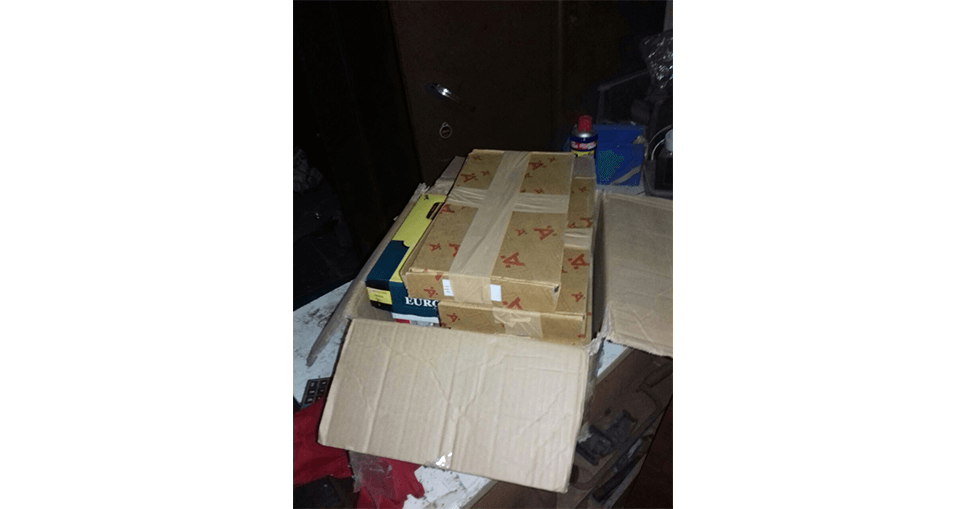

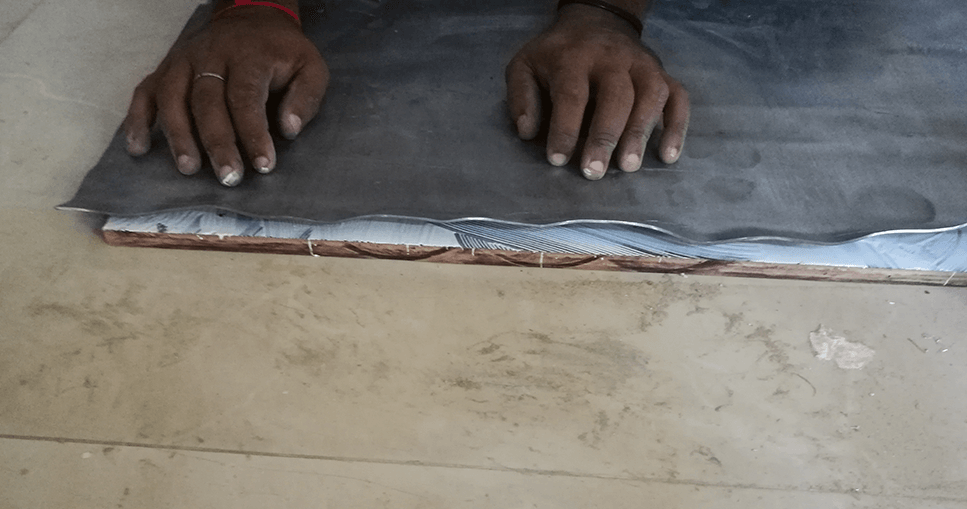

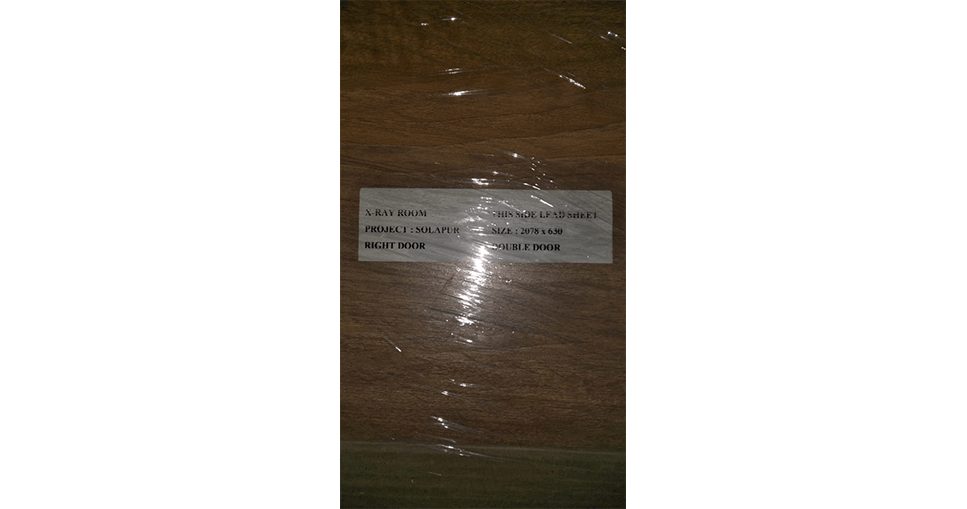

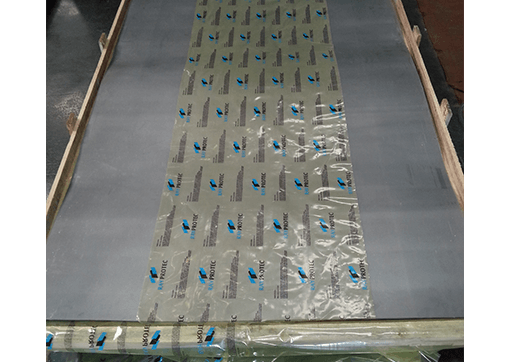

Packing

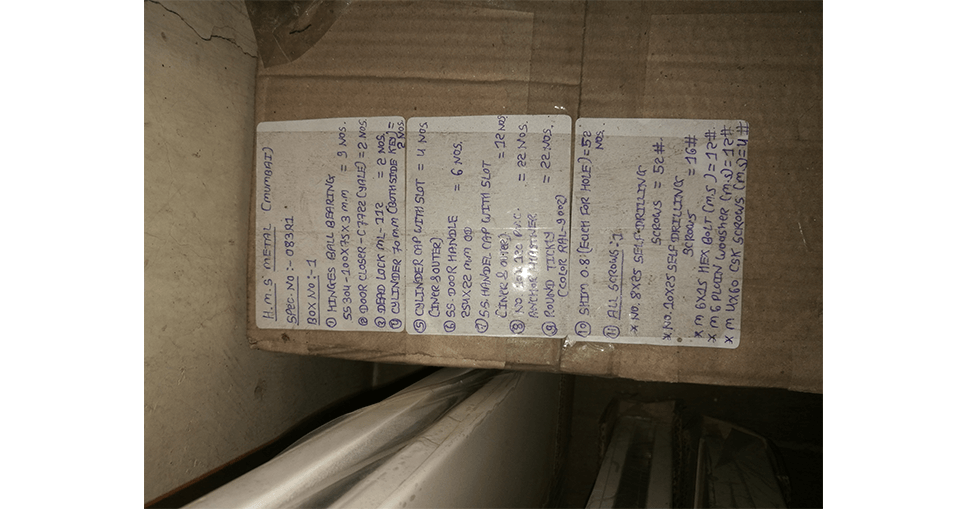

Each roll of Lead Sheet is wrapped with HDPE Plastic sheet to avoid any kind of transit damages. Further our Product Colour Code labeling and marking helps your warehouse keeper/production floor people easily label out the required size.Our export worthy packing makes sure that our product reaches you safely and without any damages in transit.

Our export worthy packing makes sure that our product reaches you safely and without any damages in transit.

Storage

Lead is one of the heaviest metals in use in the modern world. Care must be taken to ensure that if lead sheet is stored above ground level, the means of storage is strong enough to accept the weight of the product.

Irrespective of the method of storage, lead sheet must be kept in a dry environmentuntil the application phase to ensure that no unsightly staining can occur if the storage area is damp.

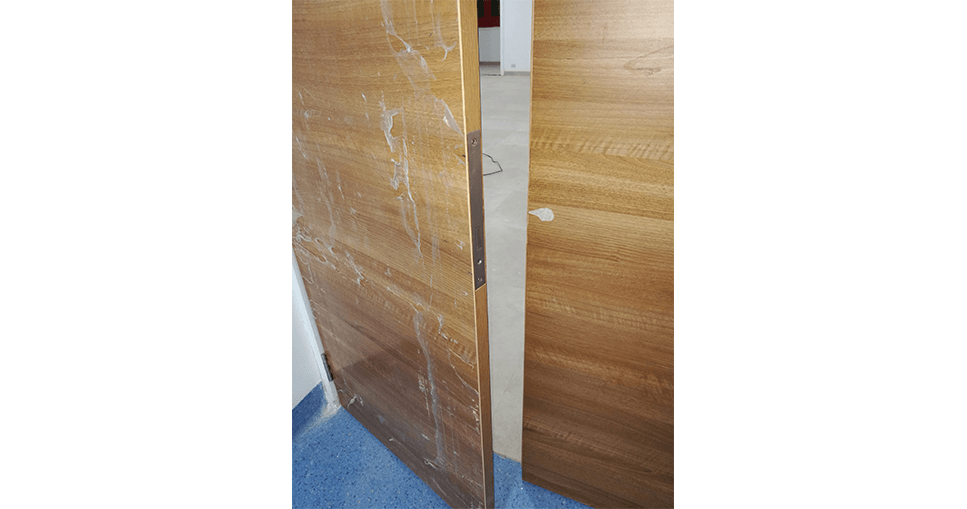

Surface of Lead Sheet can be scored or damaged if it comes into contact with rough surfaces or sharp objects.

Handling

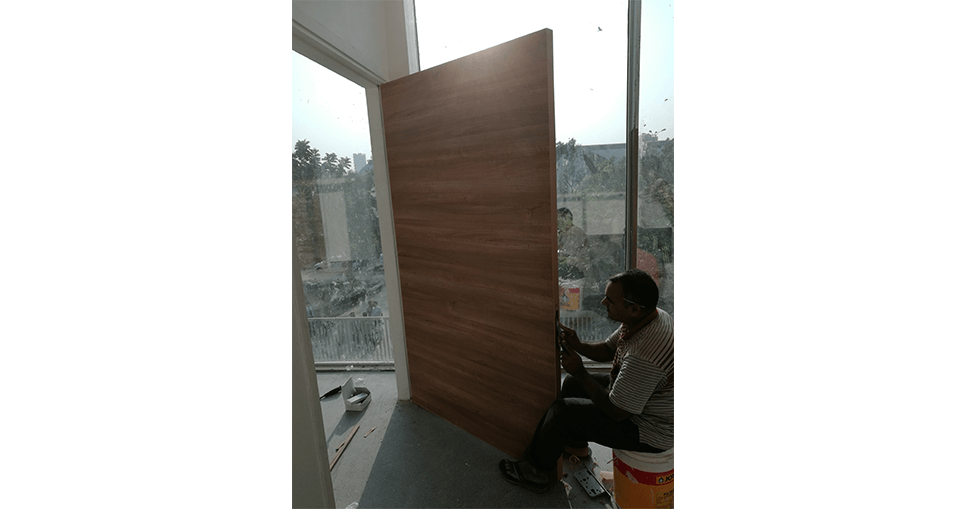

Lead is a soft heavy metal this brings advantages during application but caution must be exercised in handling. Lift with Proper lifting equipment - seek assistance where necessary.

Always ensure the safety of operatives lifting and moving Lead sheet.

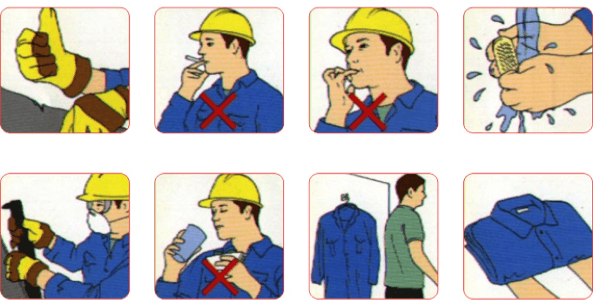

PERSONAL PROTECTIVE EQUIPMENT (PPE) to be used while handling lead.

Eye/Face Protection: Wear safety goggles.

Skin Protection: Wear protective clothing e.g. gloves, aprons, boots.

General Hygiene Considerations while handling Lead: It is good practice to

avoid breathing product; avoid skin and eye contact and wash hands after handling.

Health & Safety

Wear the appropriate protective clothing & gloves when handling Lead.

Wash your hands and forearms as soon as you finish and before you eat or drink.

For health and safety reasons it is recommend there be no exposed lead after your installation is completed. Disposal of all scrap lead must be handled in a proper environmentally & responsible manner. Check with your local by-laws for the proper way of disposing of the remaining scrap lead material. Installation should comply with requirements of local regulatory agencies and standards specified.

Delivery Time

Standard size are always available for immediate deliveries. Ask for delivery times when dealing with customised orders.

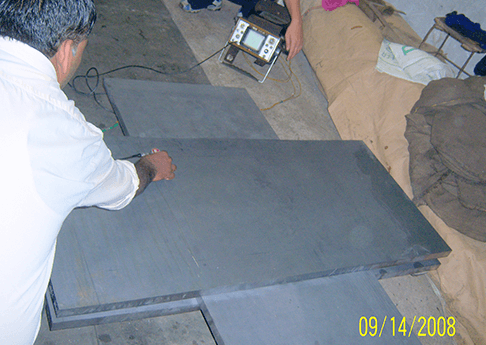

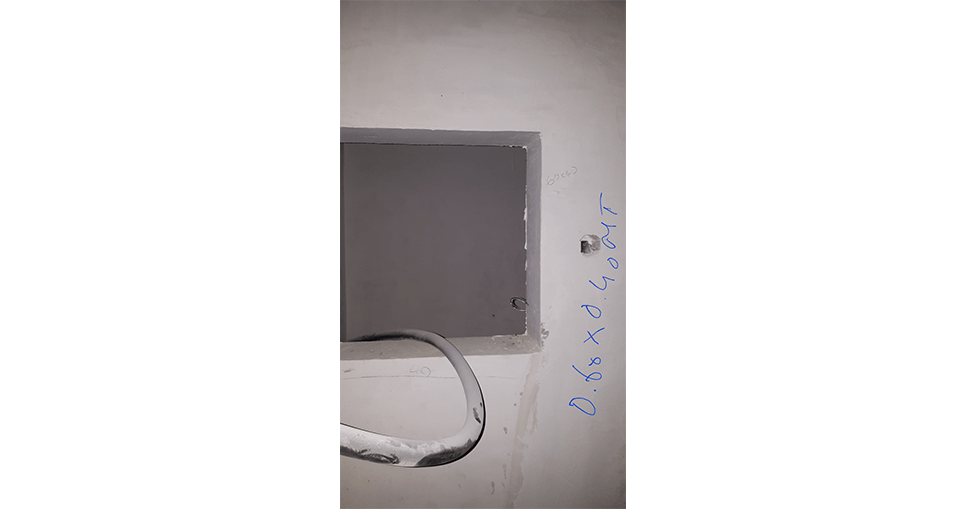

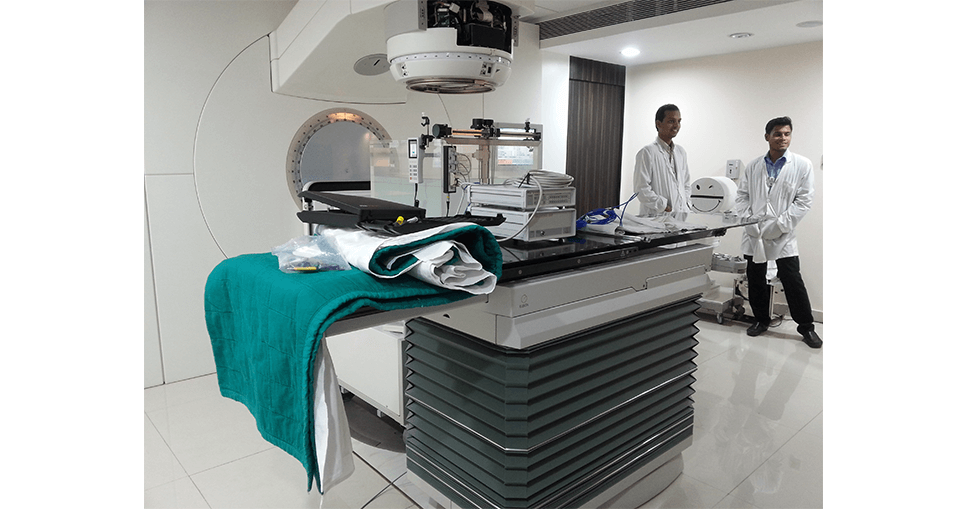

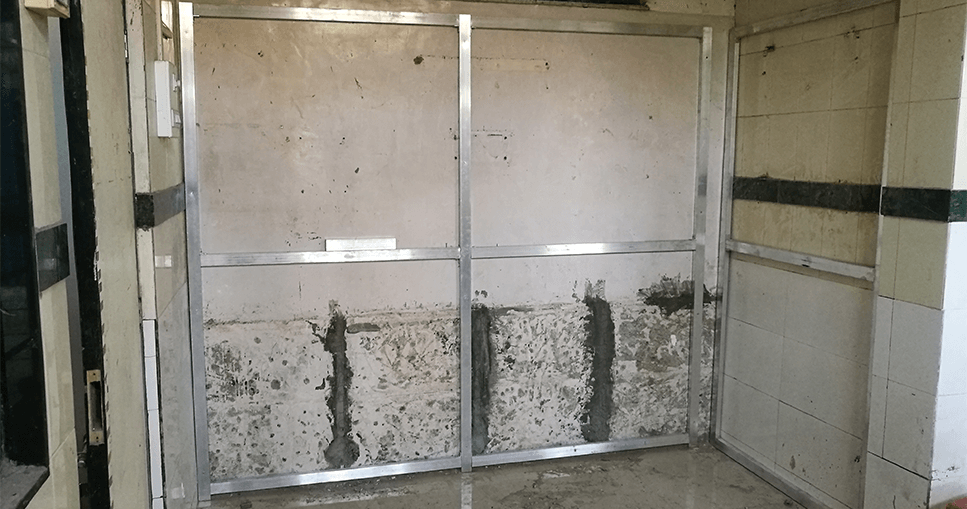

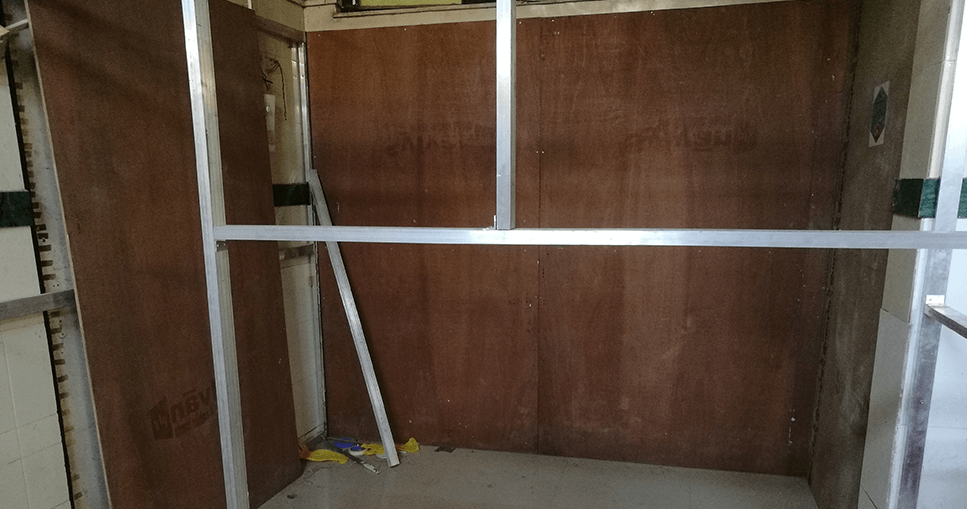

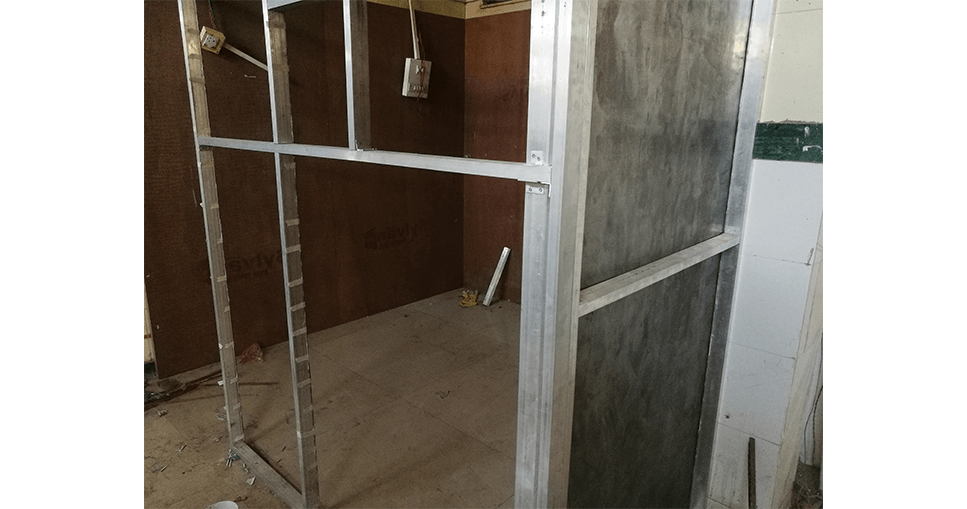

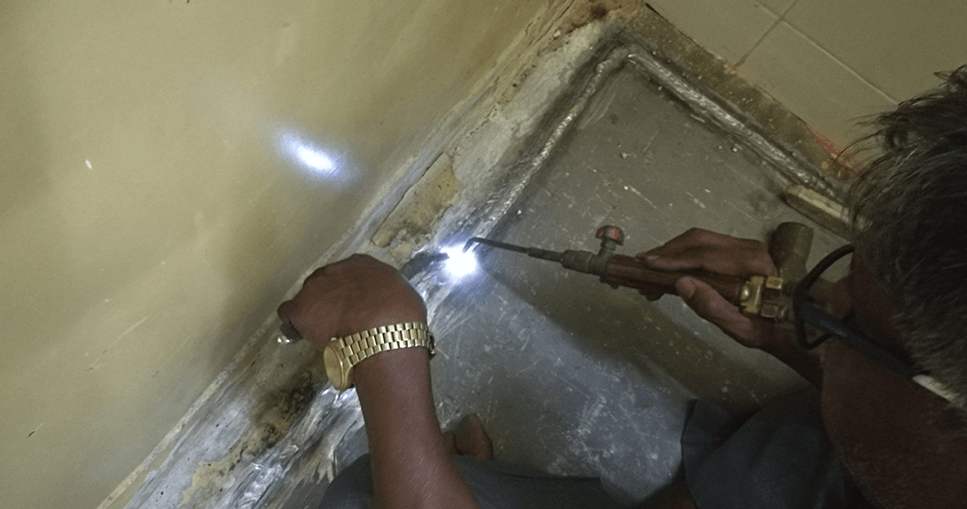

Execution

Lead must be protected from public contact after installation for both environmental and health reasons. Lead sheet, plate and brick are normally installed behind other materials and away from exposure to the public. Installers should be trained in safe handling of lead and must observe proper techniques for installation and cleanup.

Recycalibility

Rolled lead sheet is totally recyclable. Scrap material is recovered from end of life and channeled back to the manufacturers where it is carefully refined and use. To its proven performance, lead is an environmentally friendly product and it is 100% recyclable. Thus lead has a small impact on global warming.

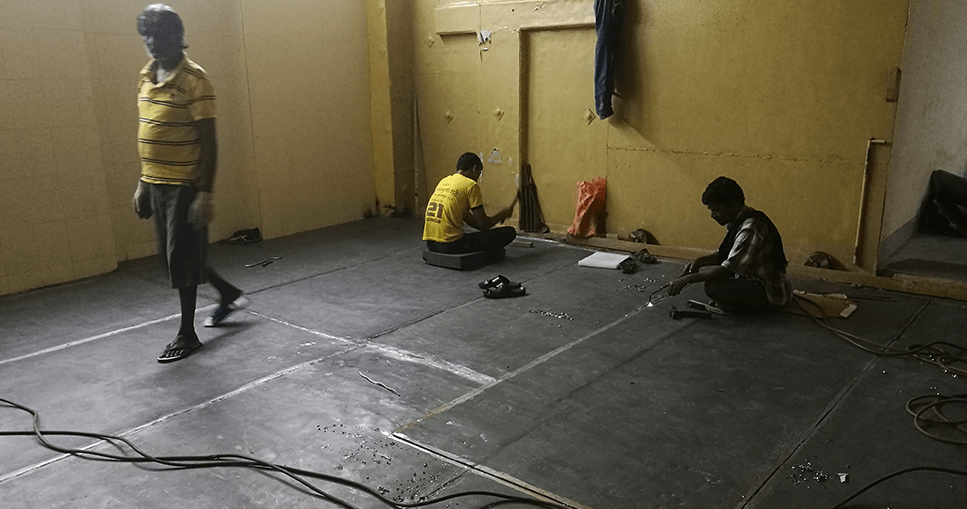

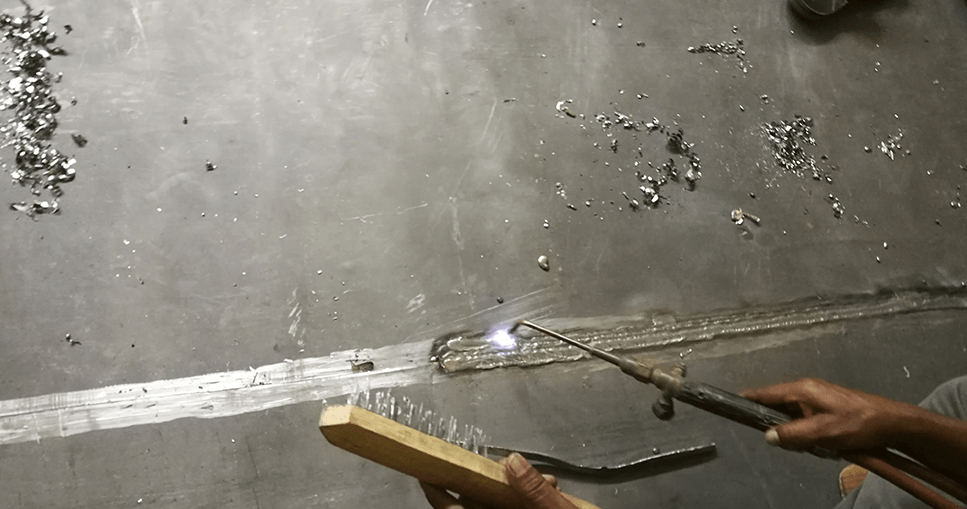

MANUFACTURING PROCESS

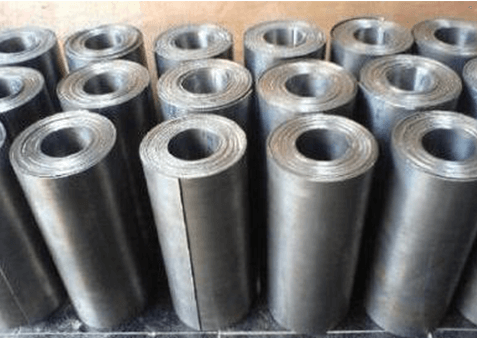

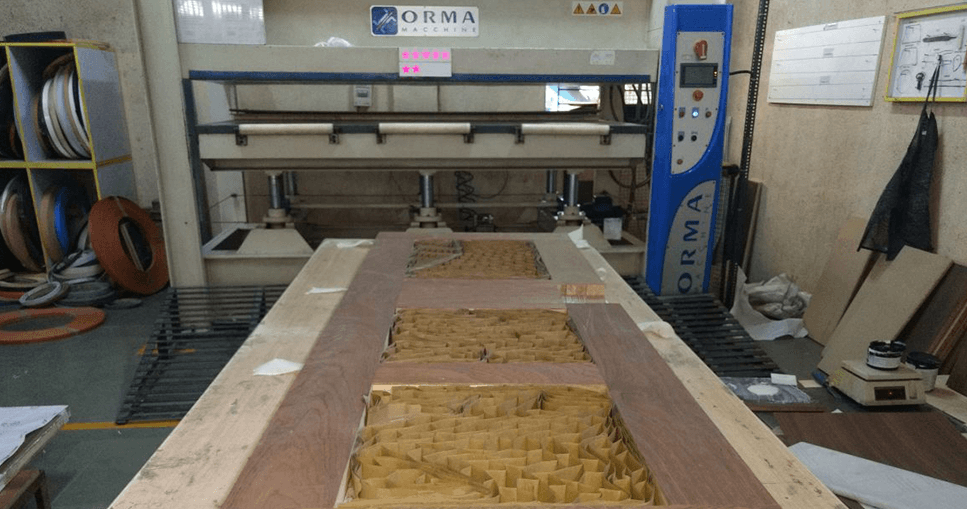

Lead sheet is formed by passing a slab of refined lead back and forth on a rolling mill between closing rollers, to a predetermined thickness. The sheet is then slit to width and cut to length for final packing and distribution. Such is the consistency of the process that lead sheet will not vary in thickness by more than +/-5% at any given point.

Melting

Re-rolling

Cutting

Packing