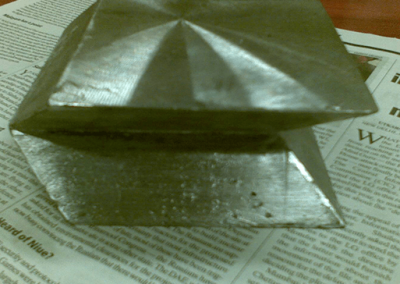

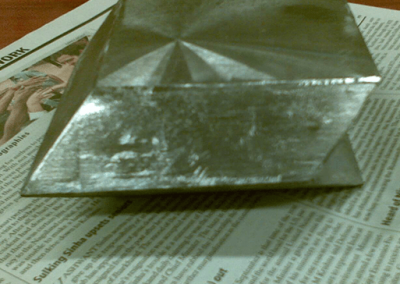

We can Fabricate Lead Bricks (cast interlocked bricks or extruded straight bricks) used in various radioactive shielding applications.

Available as straight or interlocking chevron-type in a wide range of sizes, thicknesses and shapes to suit your application. - Lead bricks offer maximum protection against x-ray beta and gamma radiation - straight lead bricks can be cut on size in any direction without the fear of losing the interlocking capability.

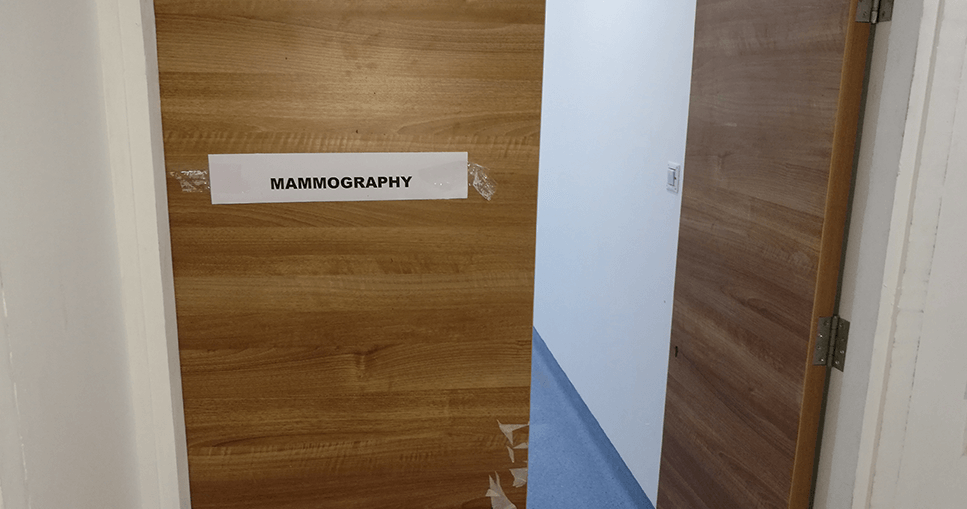

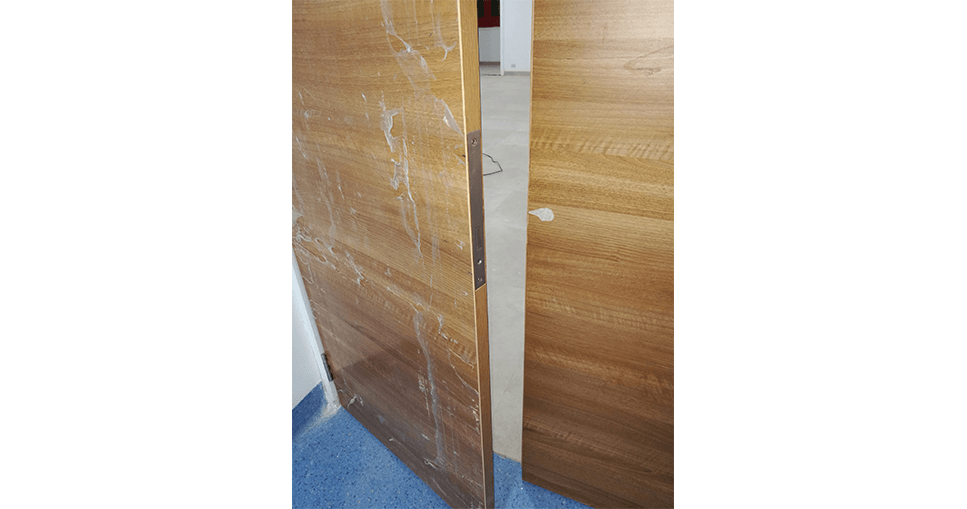

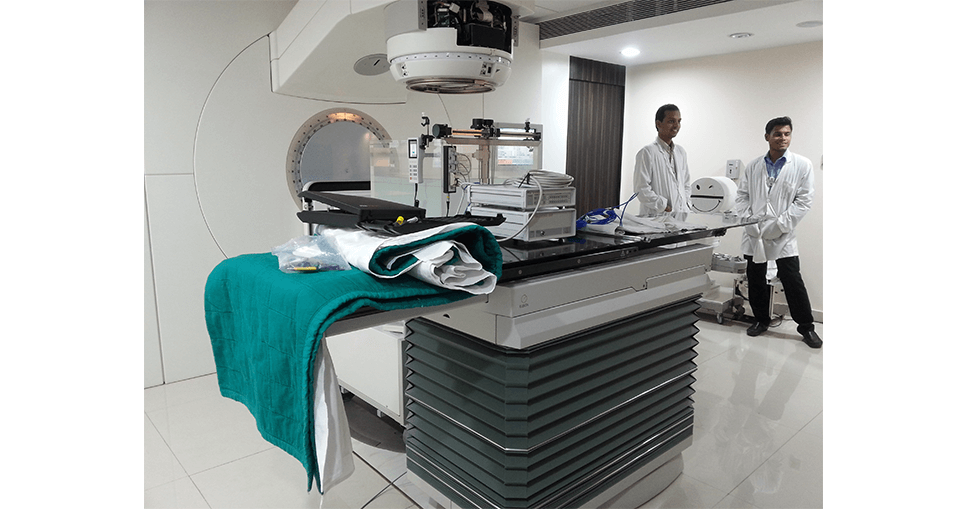

Our Lead Bricks are supplied to various contractors who undertake Radioactive shielding jobs.

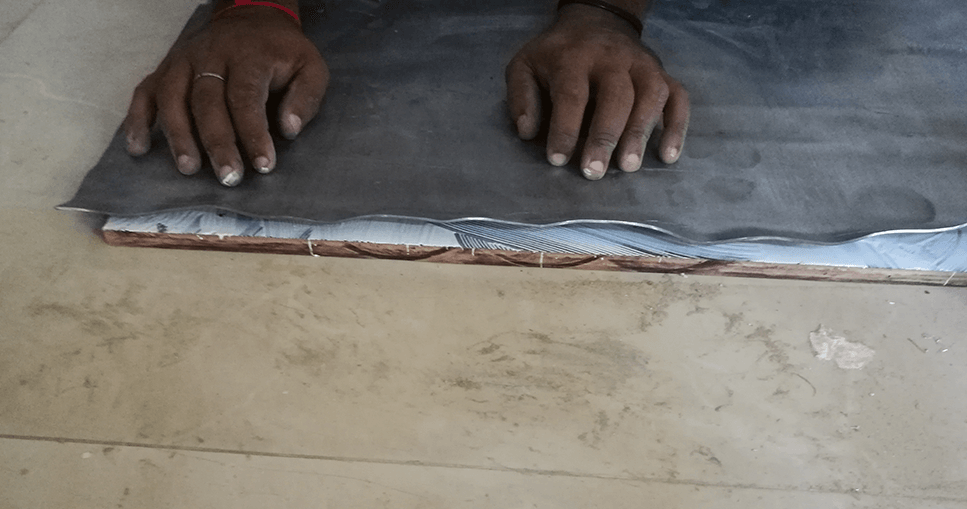

Lead brick shielding provides the best choice for construction where temporary or permanent shields or storage areas are required, offering you the flexibility in your design and construction choices. Lead bricks are ideal for adding additional shielding to existing rooms and can be used in new construction as a method to reduce wall or ceiling thickness to achieve space savings. Easy to stack, unstack and relocate, lead bricks provide maximum protection wherever needed. Produced from the highest quality lead, each brick surface is relatively flat, clean and smooth and have a non-porous surface allowing a perfectly flush fit, even at sharp right angles.

PRODUCT ATTRIBUTES

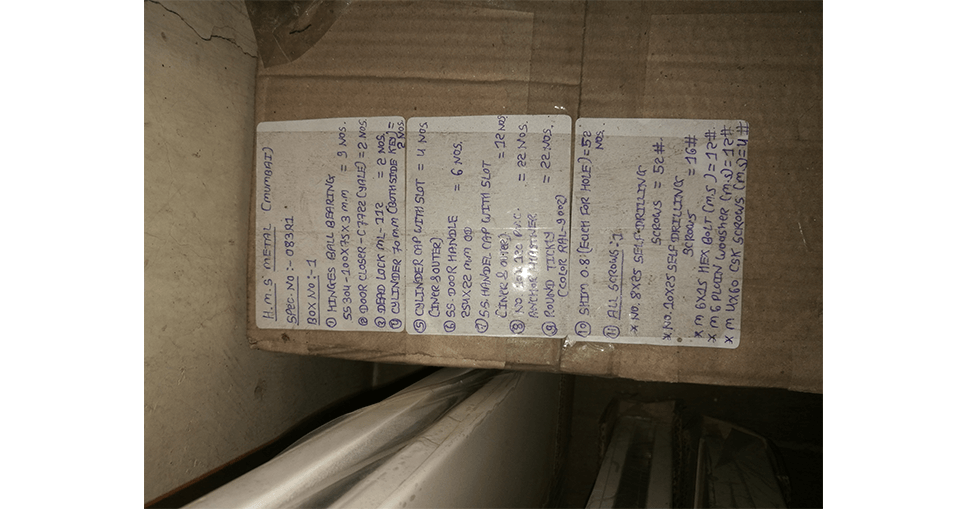

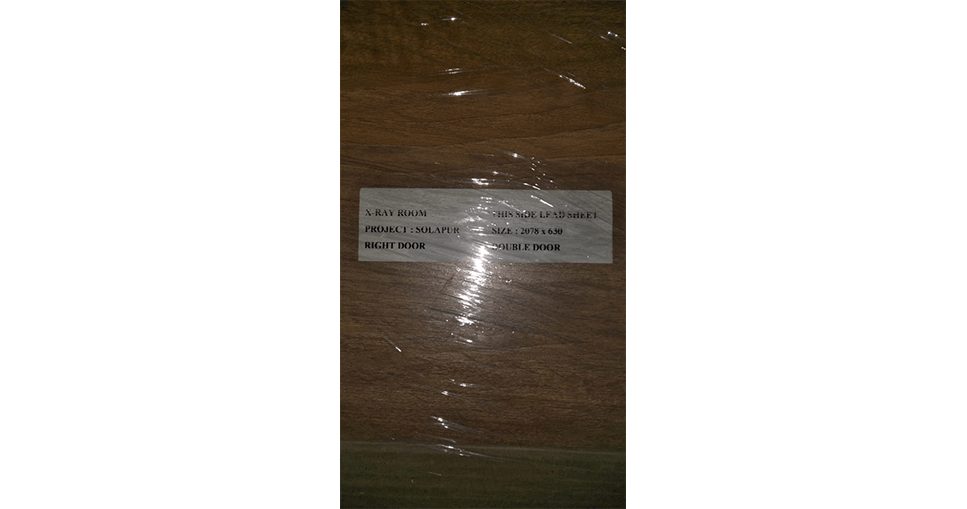

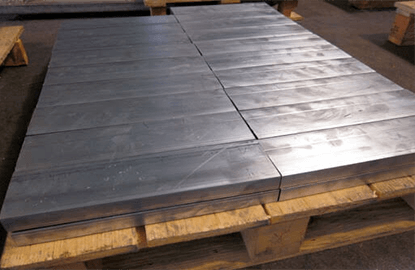

Packing

Lead Bricks are supplied in Wooden Caret box for to avoid any kind of transit damages.

Our export worthy packing makes sure that our product reaches you safely and without any damages in transit.

Required Order Information

When preparing to order, please have the following requirements available:

Size

Type of brick

Quantity

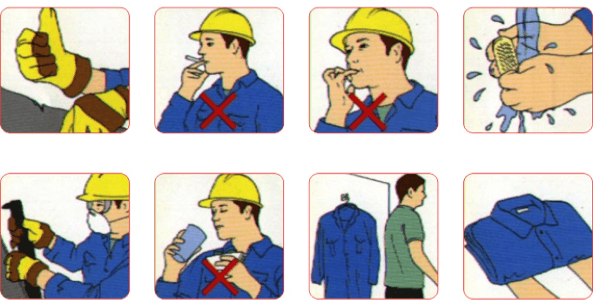

Handling

Lead is a soft heavy metal this brings advantages during application but caution must be exercised in handling. Lift with Proper lifting equipment - seek assistance where necessary.

Always ensure the safety of operatives lifting and moving Lead sheet.

PERSONAL PROTECTIVE EQUIPMENT (PPE) to be used while handling lead. Eye/Face Protection: Wear safety goggles.

Skin Protection: Wear protective clothing e.g. gloves, aprons, boots.

General Hygiene Considerations while handling Lead: It is good practice to: avoid breathing product; avoid skin and eye contact and wash hands after handling.

Health & Safety

Wear the appropriate protective clothing & gloves when handling Lead.

Wash your hands and forearms as soon as you finish and before you eat or drink.

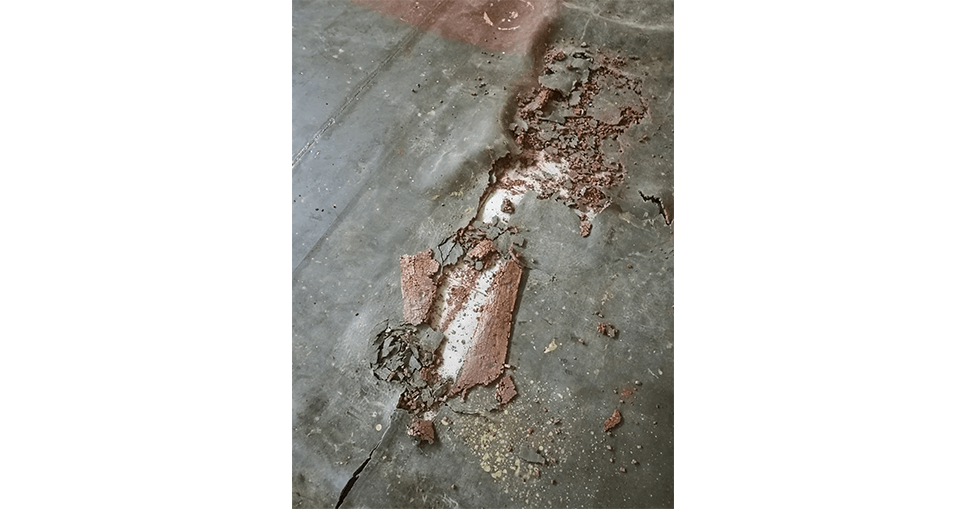

For health and safety reasons it is recommend there be no exposed lead after your installation is completed. Disposal of all scrap lead must be handled in a proper environmentally & responsible manner. Check with your local by-laws for the proper way of disposing of the remaining scrap lead material. Installation should comply with requirements of local regulatory agencies and standards specified.

Delivery Time

As Lead Bricks are custom made to size/drawing/sample. Ask for delivery times when ordering

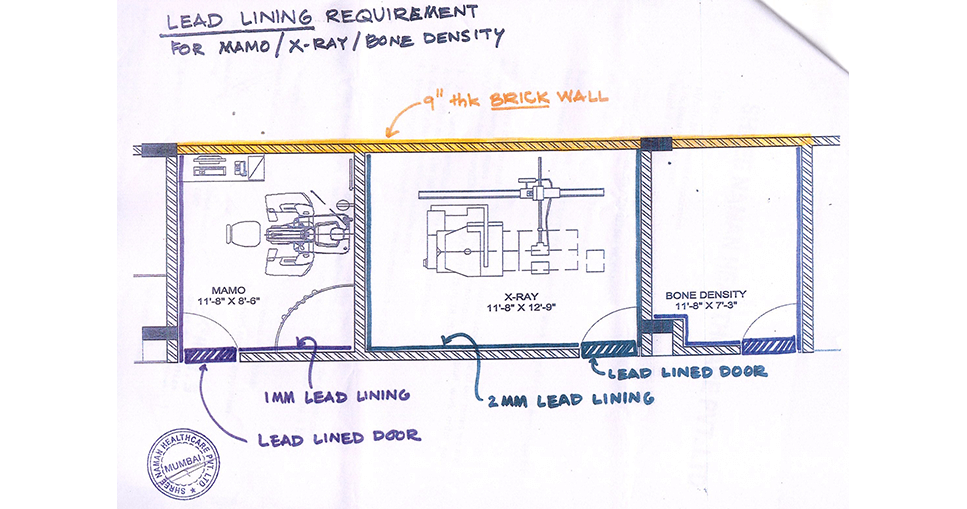

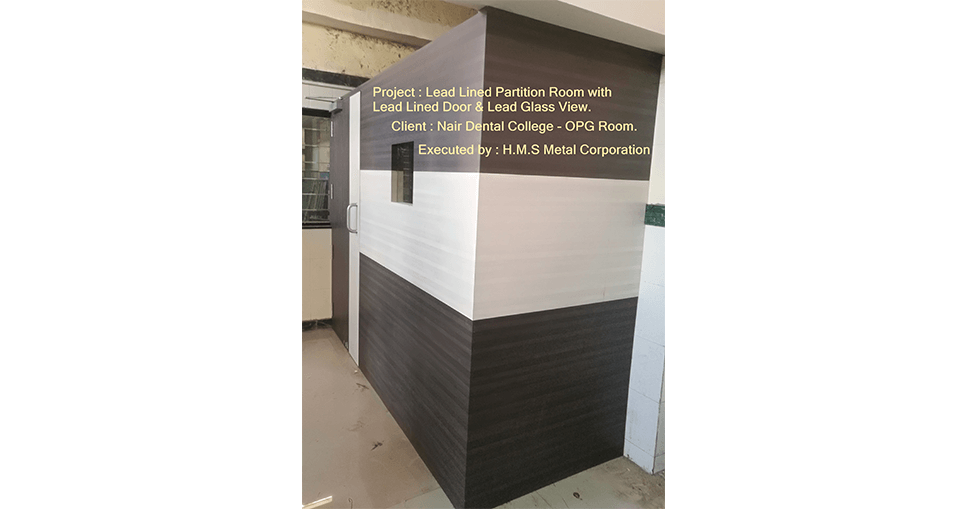

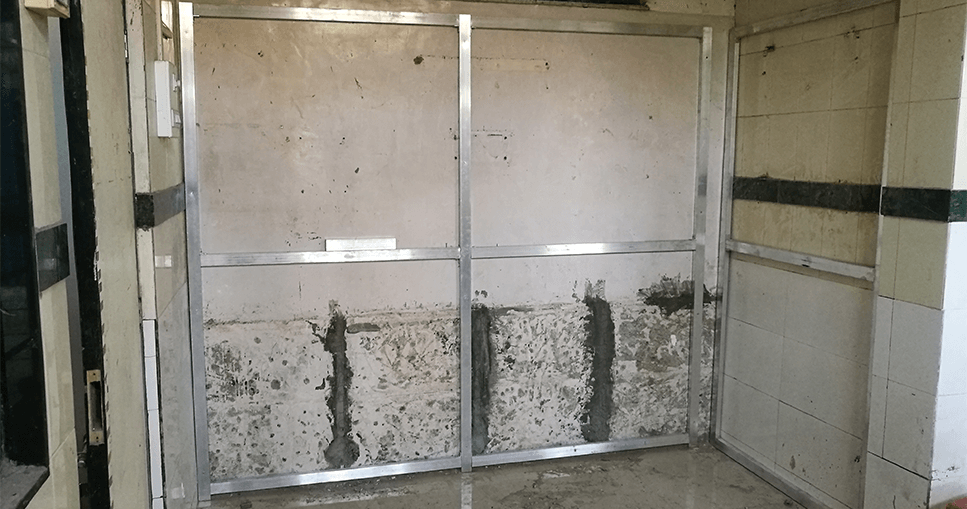

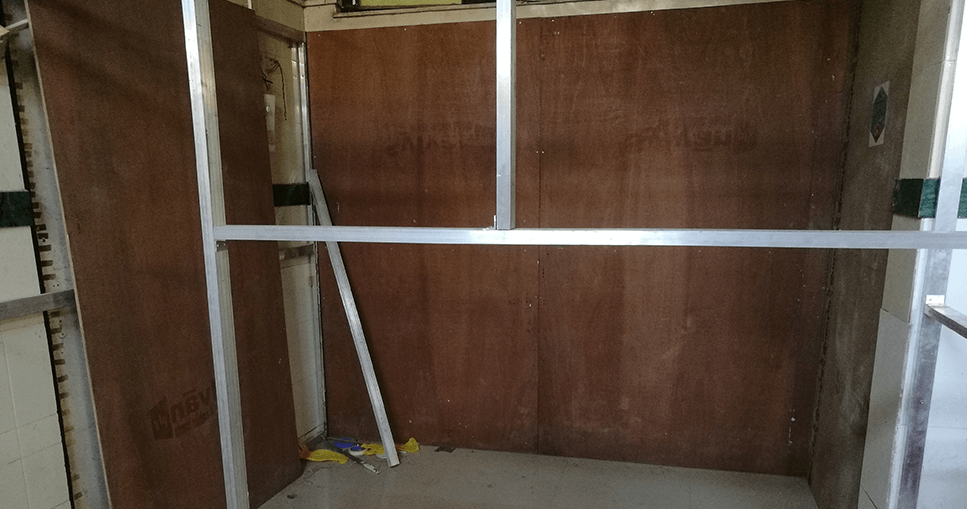

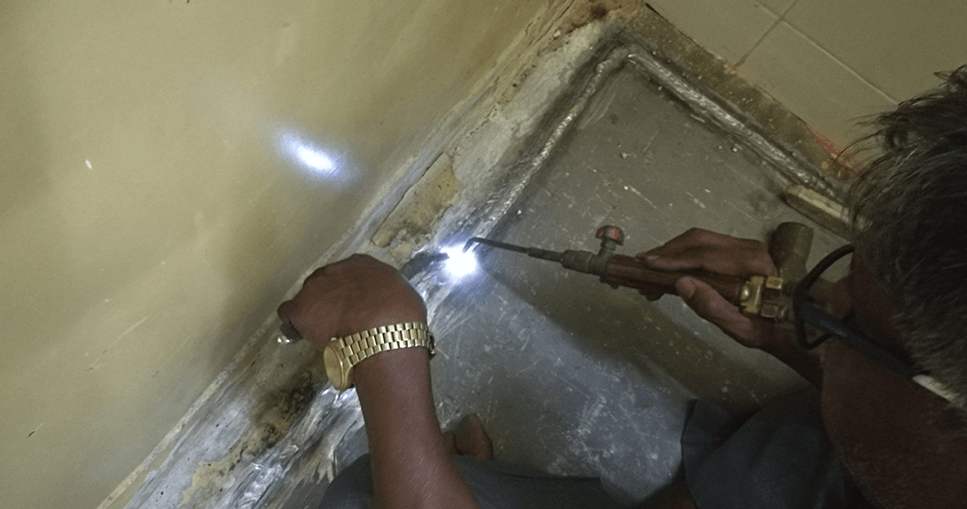

Execution

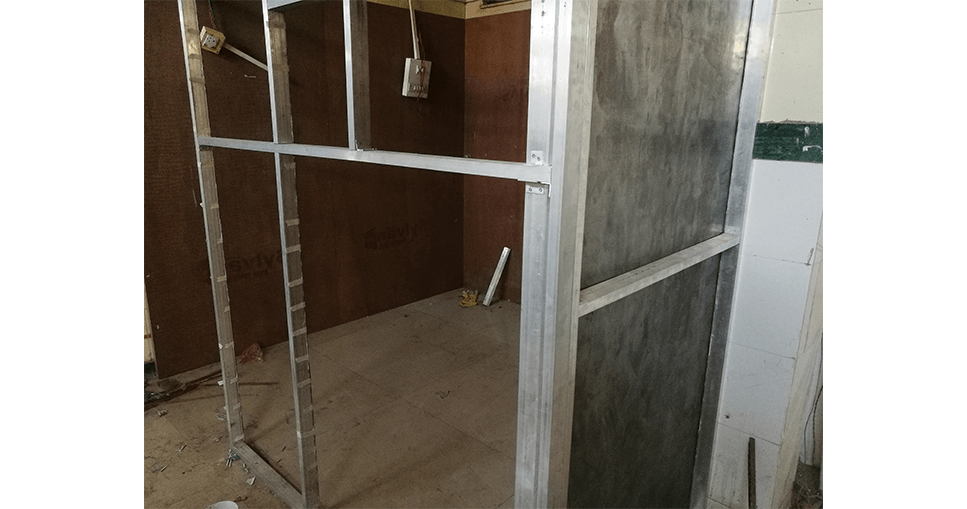

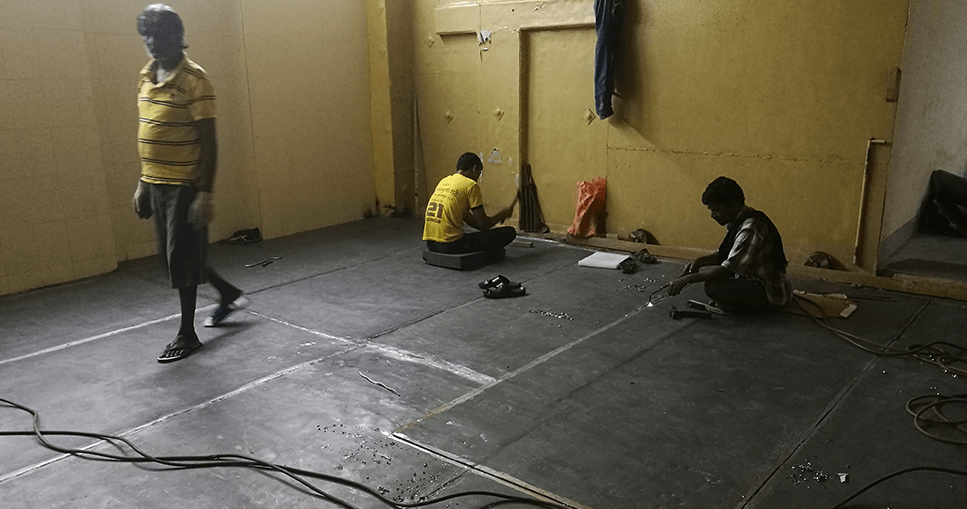

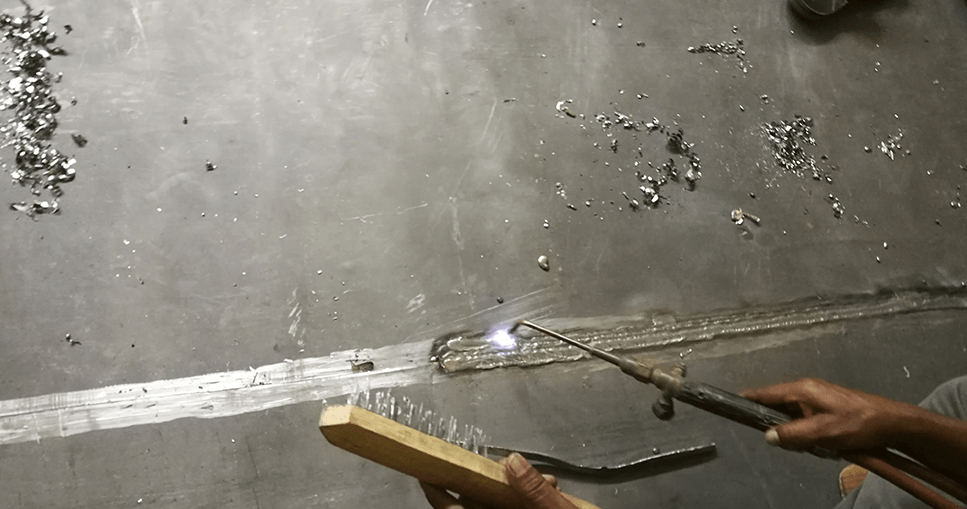

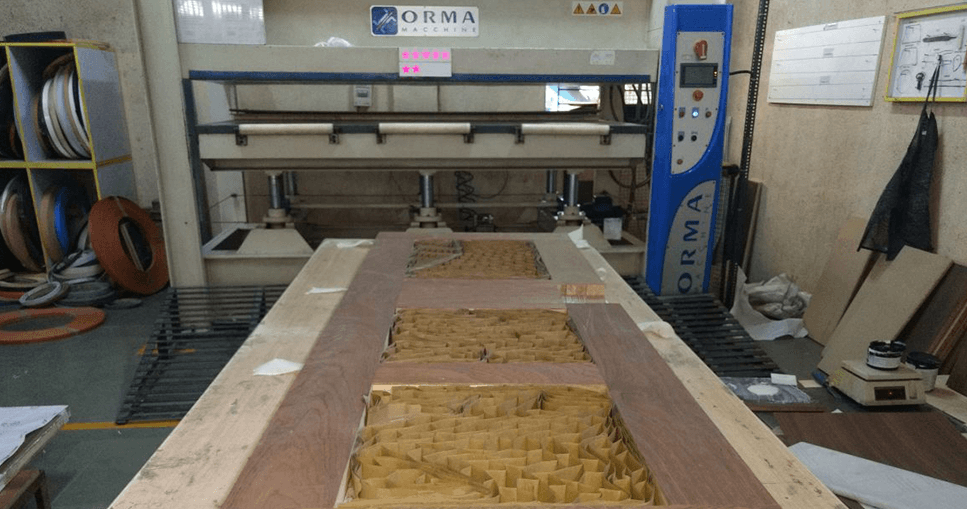

When installing lead bricks, the best method of installation is to have the lead bricks sandwiched between two rows of studs or steel tubing, or between a concrete wall and a row of studs. Installation of the lead bricks using this sandwich method enables conduit and cabling to be run without concern for cutting through the lead brick wall. In all cases, the design of the lead brick wall should not allow for any penetrations in the wall as this causes issues logistically, financially and with safety.

Recycalibility

Disposal of all scrap lead must be handled in an environmentally responsible manner. Consult the factory for information and assistance in any aspect of installation when this need arises.